Reliable performance while withstanding washout by water and aggressive cooling fluids

Manufacturers use increasingly aggressive cooling fluids in clamping mechanisms, such as lathe spindles, so lubricants must be highly resistant to reduce downtime and minimise relubrication cycles. This is just one of the potential applications for Molykote P-1042, due to its unique characteristics whenever you need to withstand very high loads and the presence of water or chemicals this product is the solution.

MOLYKOTE® P-1042 Adhesive Grease Paste offers:

Performance needs

- High load-carrying capacity

- Outstanding resistance to washout by water and metalmachining emulsions

- Tribo-corrosion avoidance

- Stick-slip prevention

- Excellent protection against galling

Advantages

- Provides the desired and prolonged level of clamping force

- Reduced downtime and re-lubrication

- Hazard-free no risk phrases

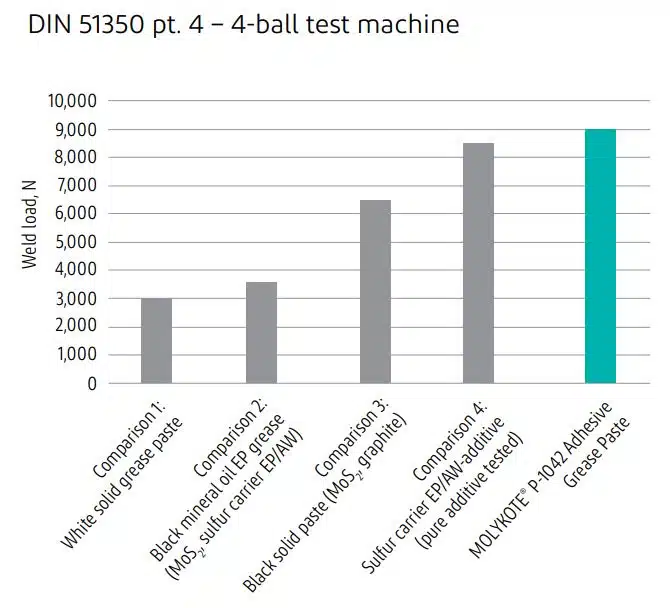

High load-carrying capacity

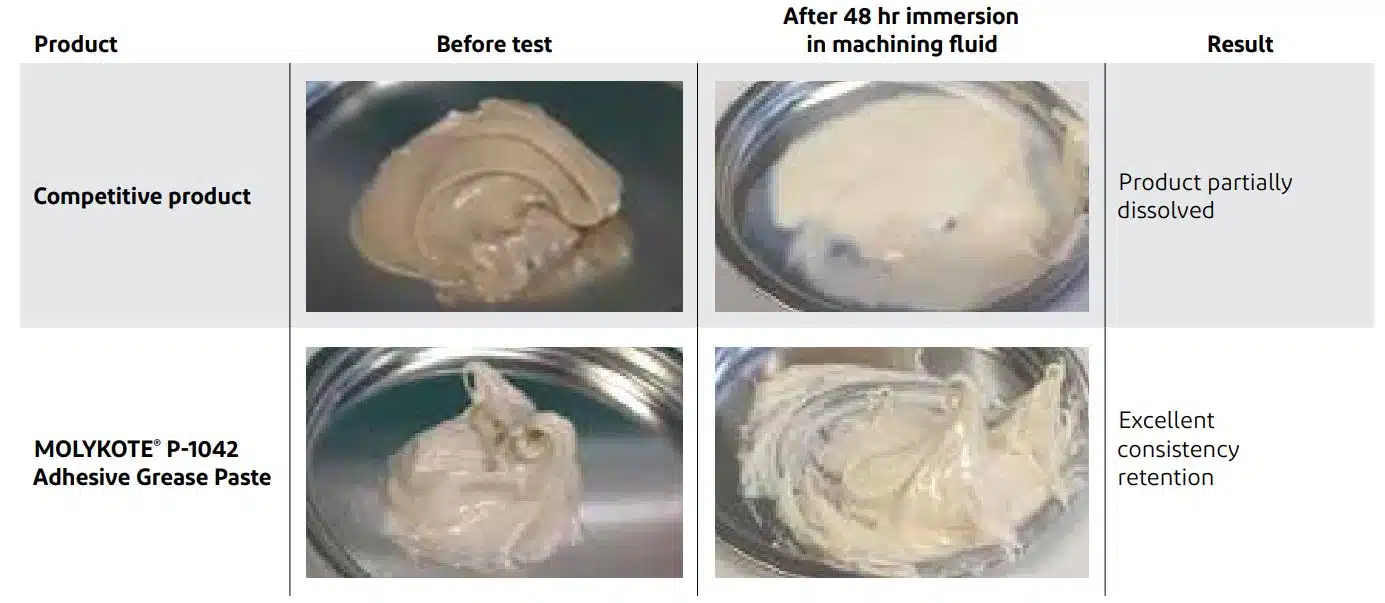

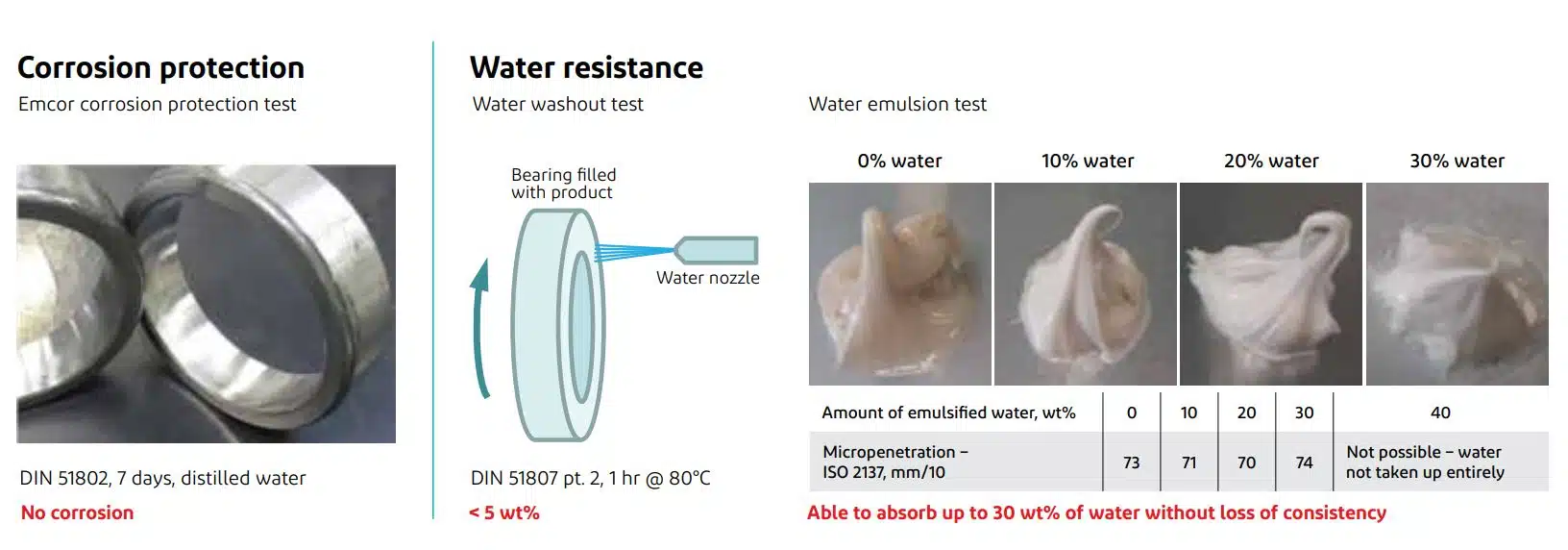

Outstanding resistance to washout by water and metal-machining emulsions

As manufacturers use more aggressive cooling fluids in metal machinery and clamping mechanisms – such as lathe chucks – highly washout-resistant lubricants with reliable tribological performance are a requirement to reduce downtime and minimize relubrication cycles.

MOLYKOTE® P-1042 Adhesive Grease Paste is a light-colored grease-paste fortified with solid lubricants, designed for sliding surfaces exposed to high-pressure loadings and subjected to the influence of water or metal-machining emulsions. With a patented formula specifically designed to properly lubricate clamping mechanisms, MOLYKOTE® P-1042 Paste enables manufacturers to deliver consistent clamping force on lathe chucks. Additionally, MOLYKOTE® P-1042 Paste does not experience hardening issues during service.

Static machining fluid compatibility test

Grease submerged in machining fluid emulsion at 23°C and occasionally stirred by hand to test whether it can be dissolved in the emulsion

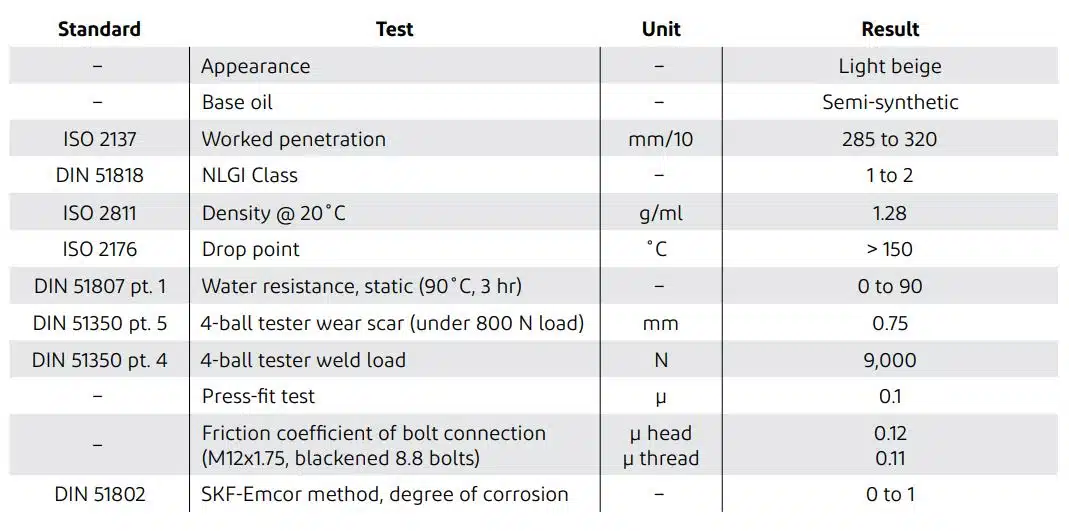

Typical properties

Specification writers: These values are not intended for use in preparing specifications. Please contact your local MOLYKOTE® sales representative prior to writing specifications on this product.