What is liquid silicone rubber?

In today’s guide, you will learn the benefits of liquid silicone rubber (LSR). Besides, we will provide detailed technical information on LSR. It is a high-performing, long-lasting material that can reliably perform in a variety of harsh environments, enabling the development of safe, adaptable and more sustainable products.

Dow’s portfolio (one of our certified brands) includes specific LSR formulations marketed under multiple brands. Within the range, you can find Injection-molding grades, coating grades, a 3D printing grade, electrical grades, optical grades as well as LSR color masterbatches. It is important to note that these meet safety standards and requirements for food contact, water contact and infant care applications.

Why choose liquid silicone rubber?

Liquid silicone rubbers offer a “magic combination” of properties, process and performance to help extend design possibilities for small parts, intricate designs, high precision and overmolding.

- It is composed of two parts in a 1:1 ratio

- They are easily mixed

- They are quickly heat-cured

Some of the key features of cured LSRs include: good mechanical properties and excellent resistance to weathering as well as extreme temperatures and aging. Moreover, fluoro liquid silicone rubber (F-LSR) combines excellent fuel and oil resistance with LSR processing economy

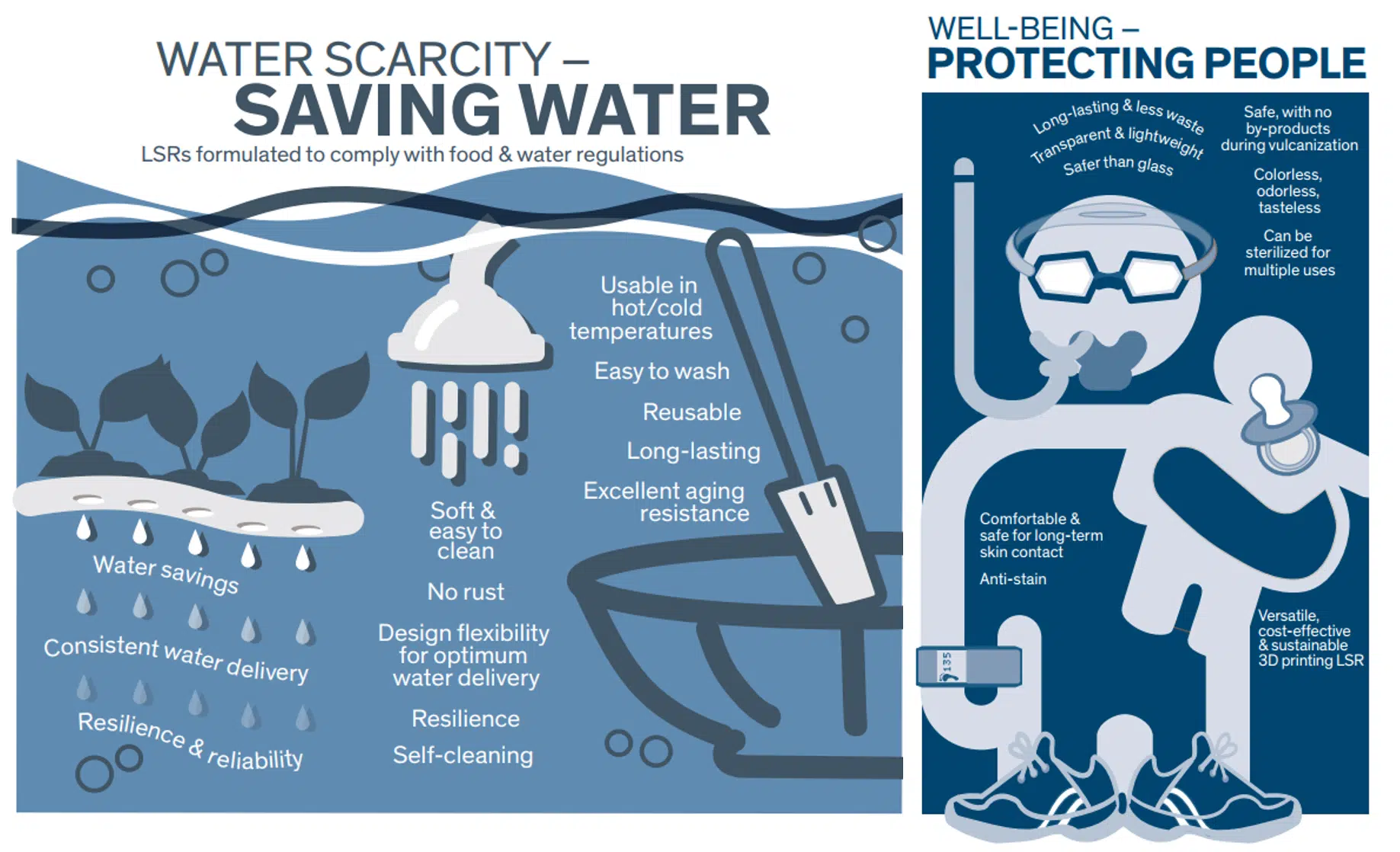

Implementing liquid silicone rubber for a more sustainable world

As manufacturers, we have a responsibility to use the most respectful and harmless materials to the environment. Dow is committed to delivering solutions that address world challenges, as we aspire to redefine the role of business in society.

For that reason, with our world-leading operations performance we address natural resource efficiency, supply chain optimization, environmental stewardship, and human health and safety. And just as important to us is delivering breakthrough innovations that enable our customers to address the needs of a rapidly changing world.

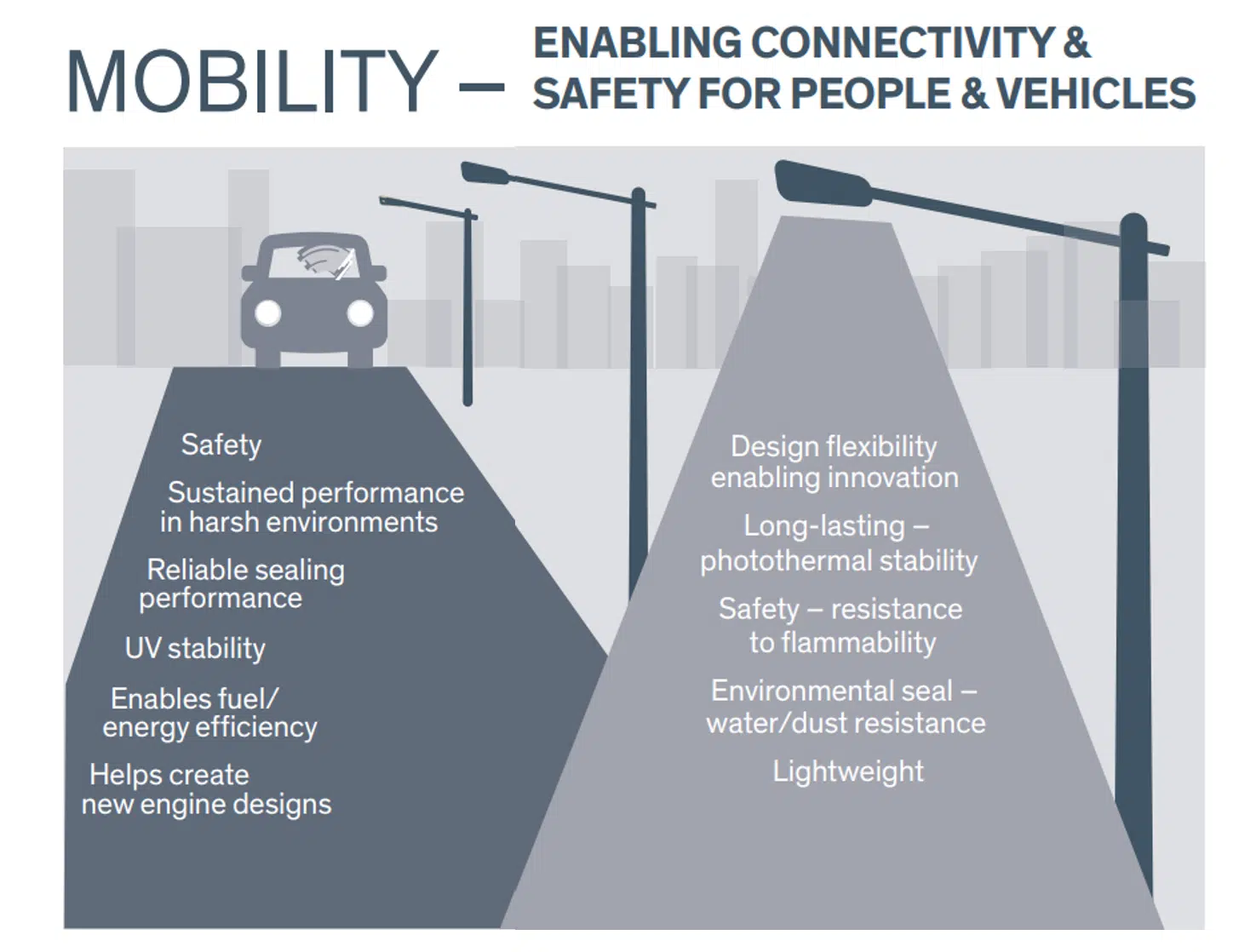

How LSRs are contributing to everyday life in an ever-more-challenging world (H3)

Liquid silicone rubbers produce less waste and require less energy for processing. Some of its key benefits are the following:

- Design flexibility, enabling innovation

- Long-lasting photothermal stability

- Safety, as it is resistant to flammability and to long-term contact

- Environmental seal, as it is water and dust resistant

- Transparent and lightweight

- Versatile and cost-effective

- Colorless, odorless and tasteless

- It can be sterilized multiple times

General purposes of Liquid Silicone Rubbers

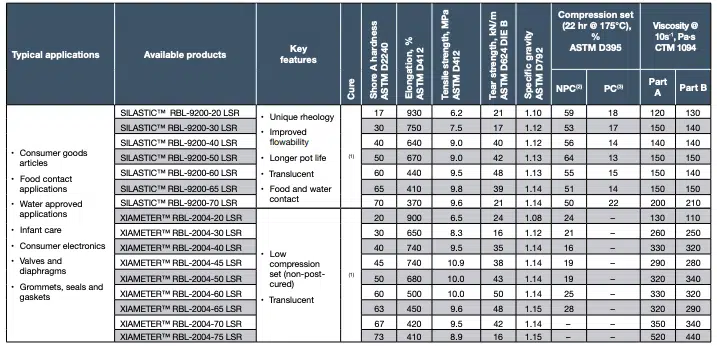

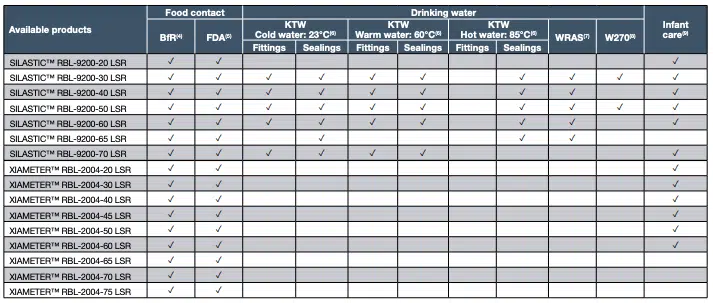

SILASTIC™ RBL-9200 series LSR elastomers and XIAMETER™ RBL-2004 series LSR elastomers are general-purpose injection-molding materials suitable for a wide range of typical silicone rubber applications.

Regulatory compliance

Non-post-cure (NPC) LSRs

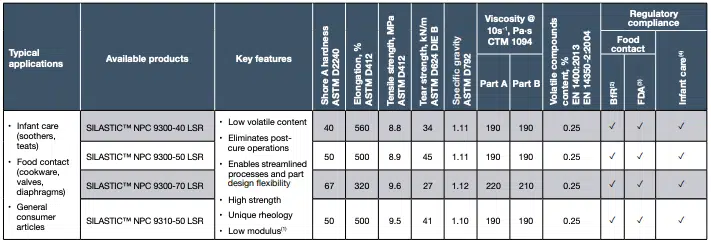

SILASTIC™ NPC 9300 series LSRs are low-volatility, high-strength silicone elastomers formulated to meet the requirements of food and infant care regulated applications without the need for post-cure.

Low-temperature-cure (LTC) LSRs

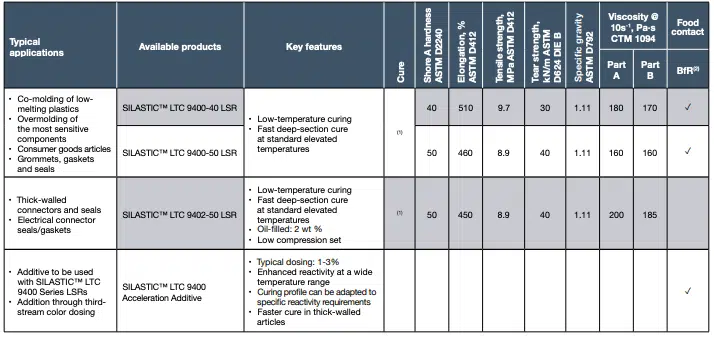

SILASTIC™ LTC 9400 series LSRs are low-temperature-curing, high-strength elastomers that enable fast temperature activation in a wide temperature range.

Oil-bleeding LSRs

A selection of oil-filled, self-lubricating LSRs is available as SILASTIC™ 920x-yy series LSRs and SILASTIC™ CV 920x-yy Series LSRs. For both, x = oil content and yy = durometer hardness. The two series of LSRs offer a choice of standard and controlledvolatility grades.

Oil-resistant LSRs

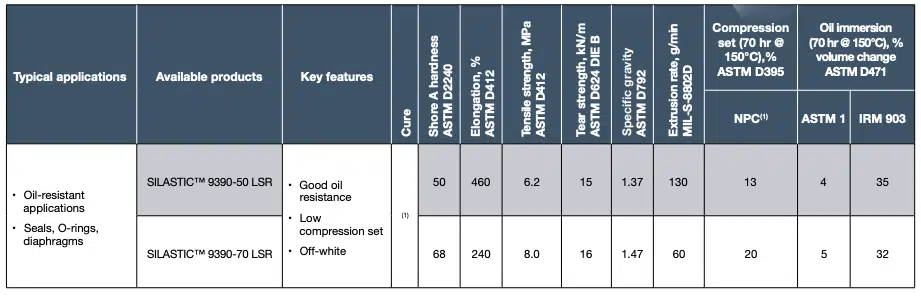

SILASTIC™ 9390 series LSRs provide good oil resistance in an off-white, injection-molding-grade elastomer for a range of air- and fluid-sealing applications.

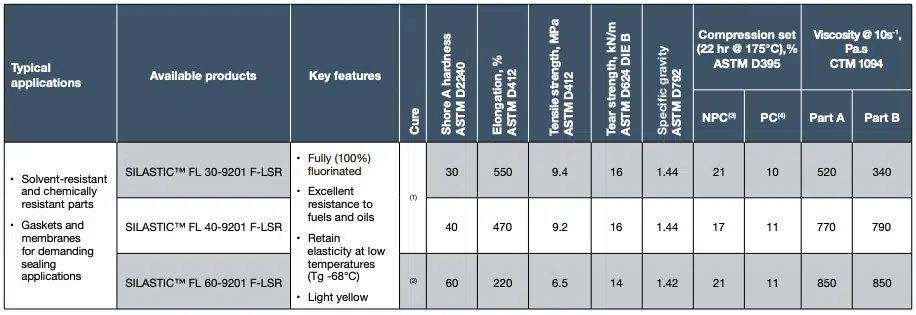

Fluoro liquid silicone rubbers (F-LSRs)

SILASTIC™ brand F-LSRs are designed for use in harsh environments involving fuel, oil or aggressive fluids. With xx = durometer hardness, these F-LSRs are available as the fully (100%) fluorinated SILASTIC™ FL-xx-9201 series. These F-LSRs combine the fluid resistance of fluorosilicone rubber with the processing ease of liquid silicone rubber using standard injection-molding equipment.

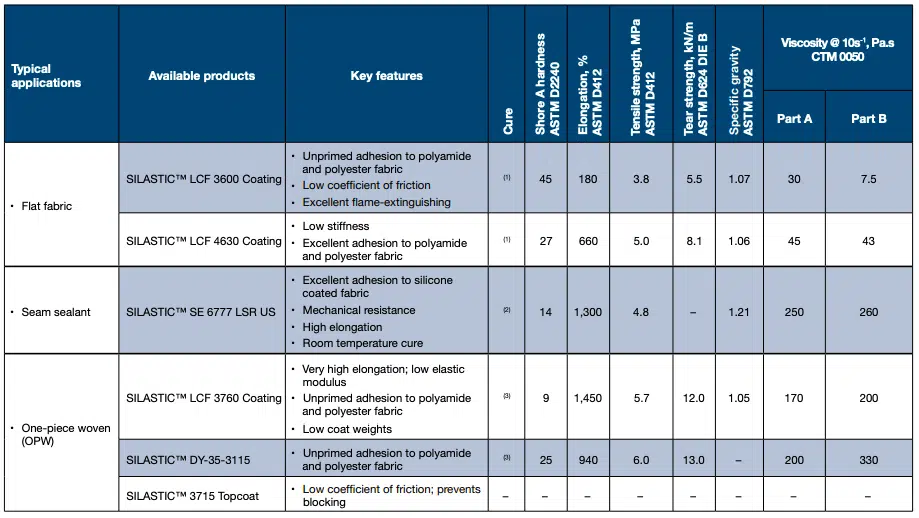

LSRs for airbag coating & sealing

LSRs for airbag coating applications includes selection of low- to medium-viscosity products designed for use on flatfabric (cut-and-sewn) and one-piece-woven (OPW) airbag designs. An engineered SILASTIC™ seam sealant is available for use on cut-and-sewn airbags.

LSRs for sleeving applications & general-purpose coating

LSRs for sleeving applications provide a range of elastomers suitable for electrical and thermal protection of wires and cables. These LSRs are available in low to medium viscosities to meet a wide range of processing requirements.

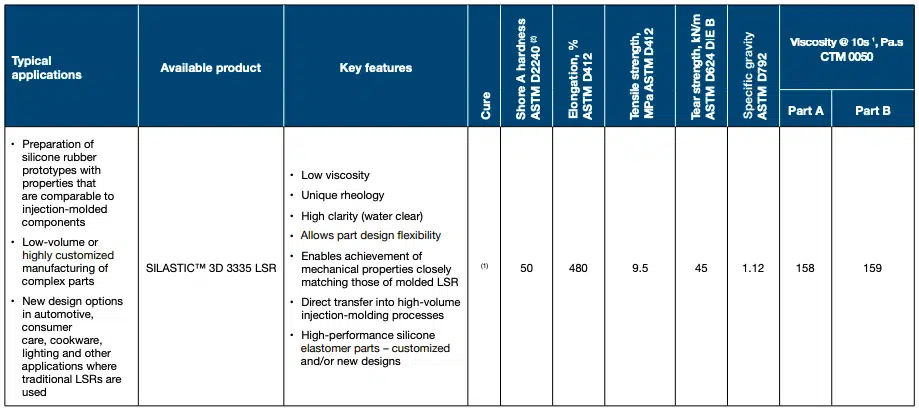

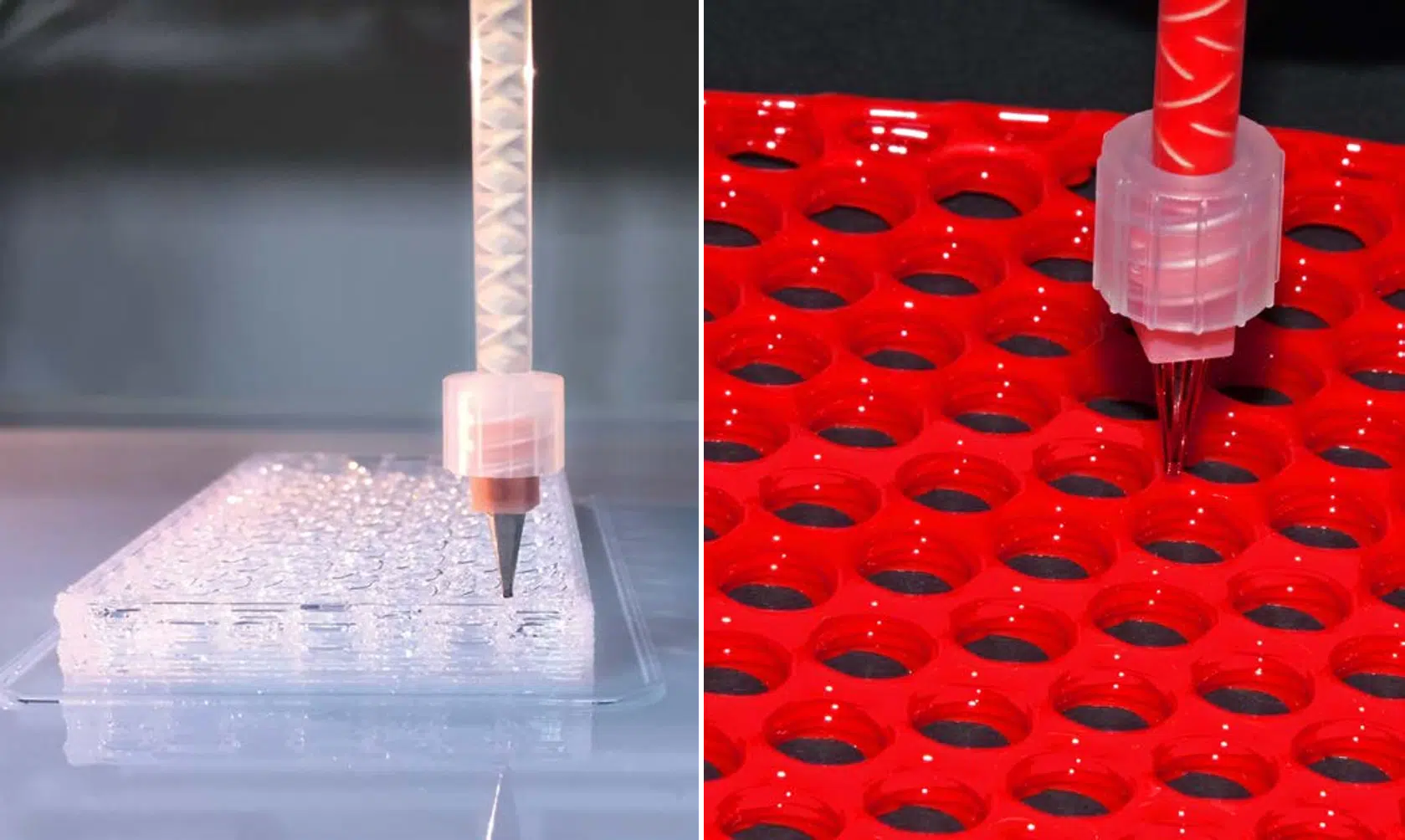

LSRs for 3D printing

SILASTIC™ 3D 3335 Liquid Silicone Rubber is a 1:1 mix LSR designed for Liquid Additive Manufacturing (LAM) 3D printing. It combines the performance benefits of silicone rubber with the design and processing advantages of additive manufacturing. The material is very transparent, which is ideal for applications where clarity and transparency are vital attributes. Compatible color packs and precision dosing equipment also give designers the ability to 3D-print this high-performing LSR in a range of standard colors.

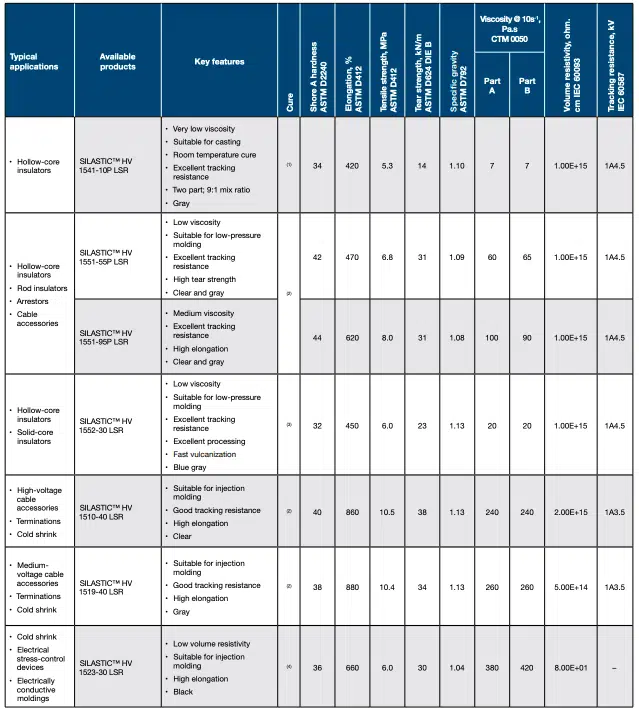

Electrical-grade LSRs

Electrical-grade LSRs provide a selection of specialty elastomers for power transmission and distribution applications.

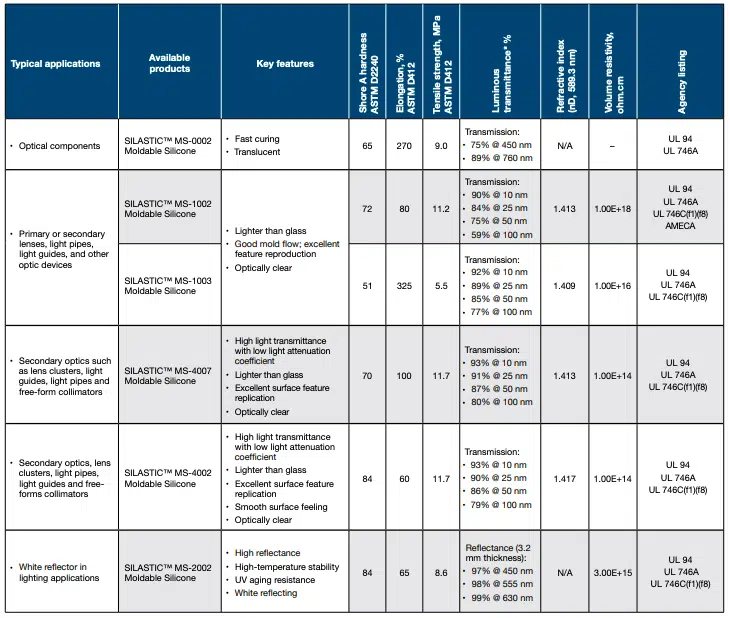

Moldable optical silicones

New-generation LED lighting concepts with silicone optical resins from Dow help increase design freedom and energy efficiency from high-performance buildings to outdoor-area illumination to advanced automotive styling. Compared to organic options, these specialty silicone liquid resins can maintain outstanding optical properties without yellowing with age under high temperatures.

LSR color masterbatches

LSR color masterbatches consist of heat-stable, cadmium-free coloring pigments dispersed in crosslinkable fluid. The XIAMETER™ brand options from Dow are specifically designed and formulated for addition to LSRs using dedicated metered mixing equipment. All are translucent LSR with 2% color masterbatch.