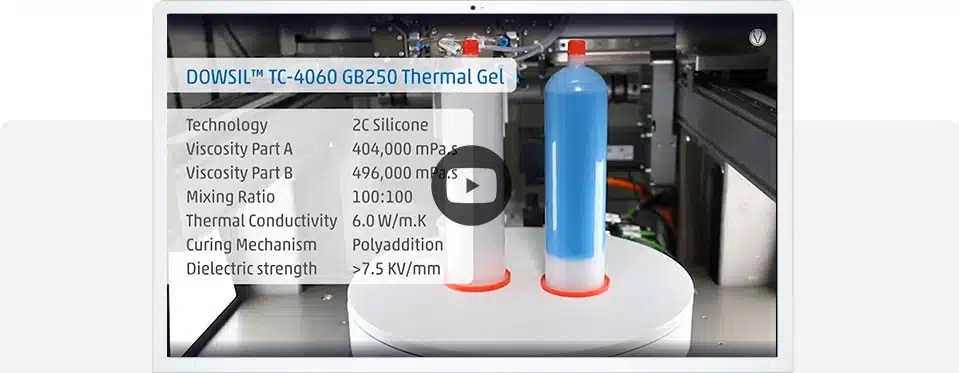

DOWSIL™ TC-4060 GB250 Thermal Gel

DOWSIL™ TC-4060 GB250 Gel is a new, high thermal conductivity material suitable for the protection of automotive electronics and telecommunication devices where heat dissipation is critical.

Key benefits:

- High thermal conductivity 6 W/m.K

- Soft, stress relieving, shock damping

- Excellent dispensing

- Long-term stability in high-temperature and high-power environments

- Glass bead 250µ to control thickness

High power density applications

Automotive electronics

- Power electronics

- Converter/inverter

- OBC

- ECU

Telecommunication devices

- Telecom power supply units

- High frequency devices (5G)

SILICONES PORTFOLIO

DOWSIL™ TC-4060 Gel / DOWSIL™ TC 4060 GB250 Gel

2K Thermal gel for automotive and telecommunications applications

- Thermal conductivity ~ 6W/mK; very easy to dispense, soft, low VOC

DOWSIL™ TC-4551 CV Gap Filler

2K Gap filler for automotive power applications

- Thermal conductivity ~5 W/mK, vertical stability before and after curing; very low VOC

DOWSIL™ TC-3060 Gel

1K Cold storage (-10°C) thermal gel for telecom applications

- Thermal conductivity ~6 W/mK, printable

DOWSIL™ TC-7006* Gum

1K RT storage thermal gum for 5G

- Thermal conductivity 6.4 W/mK, self-curing material with excellent vertical stabilit

| Test | Property |

| Two-part; Mix ratio – 1:1 | |

| CTM 0538 | Color: Part A – White Part B – Blue |

| ASTM D 2556 | Viscosity mPa-Sec: Part A 1s-1 390.000 Part A 10s-1 140.000 |

| ASTM D792 | Specific gravity (g/cm3) Parts A and B: 3.5 |

| ASTM D 2556 | Viscosity mPa-Sec: Part B 1s-1 460.000 Part B 10s-1 140.000 |

| ASTM D 2556 | Viscosity (Mixed 1s-1) mPa-Sec: 426.000 |

| ASTM D 5289 | Cure time: At 22°C 24 hours At 80°C 30 minutes |

| Test | Property |

| ASTM D 1824 | Pot life at 22°C : 80 minutes |

| ASTM D 2440 | Durometer Shore 00 after 24 hrs. at 25°C: 55 after 1 hr. at 110°C: 58 |

| E-Modulus by DMA; 0.2 MPa | |

| CTM 0137 | Tensile strength 0.05 MPa |

| ISO2 22007-2 6.5 W/m.K ASTM D 2440 5.6 W/m.K |

Thermal conductivity 6.5 W/m.K 5.6 W/m.K |

| Coefficient of Thermal Expansion 233 ± 59 ppm/°C | |

| ASTM F 2466 | D3-D12 Volatile siloxane content <100 ppm |

| ASTM D 149 | Dielectric strength 8.5 kV/mm |

| ASTM D 257 | Volume resistivity 4×1012 Ω*cm |

| DAK-TL2 | Dielectric constant 10MHz – 20GHz: 7.78 |

| UL 94 | V-0 Flammability rating |

| IEC-60112 | Comparative tracking index >600 V |

| Shelf life <40°C (104°F) 270 days |

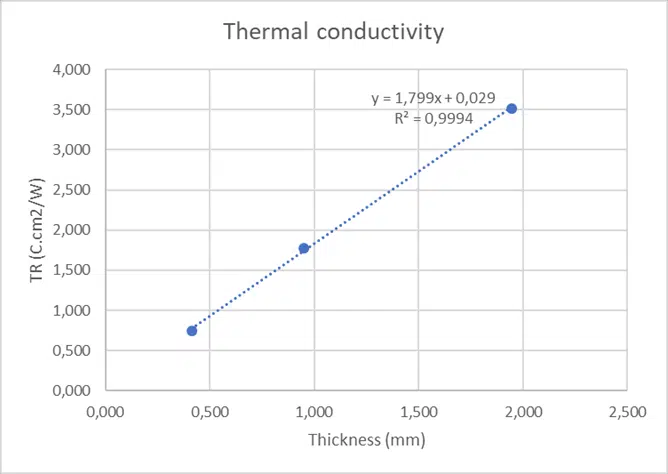

THERMAL CONDUCTIVITY

- Hot Disk: 6.5 W/mK

- ASTM D5470: 5.6 W/mK

Thermal resistance

| Thickness (mm) | Rth – (°C x cm 2/W) |

| 0,413 | 0,747 |

| 0,949 | 1,776 |

| 1,944 | 3,513 |

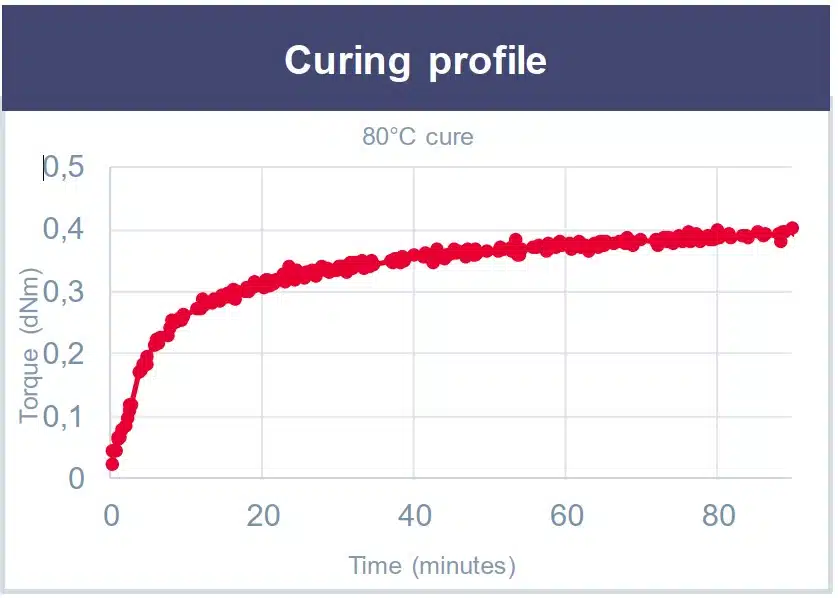

OPEN TIME AND CURING PROFILE

Open time

- 80 minutes at room temperature after mixing

- 24 hours for full cure at room temperature (up to 70 hours in hermetic confinement)

- Accelerated with 30 minutes at 80°C

- Fully cured in 1 hour at 100°C

SLUMP RESISTANCE VERSUS VERTICAL STABILITY

- Uncured material doesn’t resist vertical position

- Cured product survives all aging protocols

DOWSIL™TC-4060 Gel flipped immediately after dispensing. Picture taken after five minutes

HIGH PURITY MATERIAL

Total D3-D12 content below 100 ppm

| Client sample |

2 mm for 2 hrs at RT / 24 hrs at 25°C – 50% RH |

Part A 30 ml |

Part B 30 ml |

| D3 (ppm) | <LOD* | <LOD | <LOD |

| D4 (ppm) | <LOD | <LOD | 7 |

| D5 (ppm) | <LOD | <LOD | 6 |

| D6 (ppm) | <LOD | <LOD | <LOD |

| D7 (ppm) | <LOD | <LOD | <LOD |

| D8 (ppm) | <LOD | <LOD | <LOD |

| D9 (ppm) | <LOD | <LOD | <LOD |

| D10 (ppm) | <LOD | <LOD | <LOD |

| D11 (ppm) | <LOD | <LOD | <LOD |

| D12 (ppm) | <LOD | <LOD | <LOD |

| * Below limit of detection (<LOD) | |||

Ionic species below 5 ppm (Na below 10 ppm)

| Element | DOWSIL™ TC-4060 Gel (1) |

DOWSIL™ TC-4060 Gel (2) |

| Fluoride | 0.49 | 0.49 |

| Chloride | 0.33 | 0.33 |

| Nitrite | ND (0.1) | ND (0.1) |

| Sulfate | ND (0.1) | ND (0.1) |

| Bromide | ND (0.1) | ND (0.1) |

| Nitrate | 0.64 | 0.51 |

| Phosphate | ND (0.1) | ND (0.1) |

| Lithium | ND (0.1) | ND (0.1) |

| Sodium | 5.8 | 5.2 |

| Ammonium | 0.29 | 0.29 |

| Potassium | ND (0.1) | ND (0.1) |

| Magnesium | ND (0.1) | ND (0.1) |

| Calcium | 0.00 | 0.00 |

| Results reported in ug/g | ||

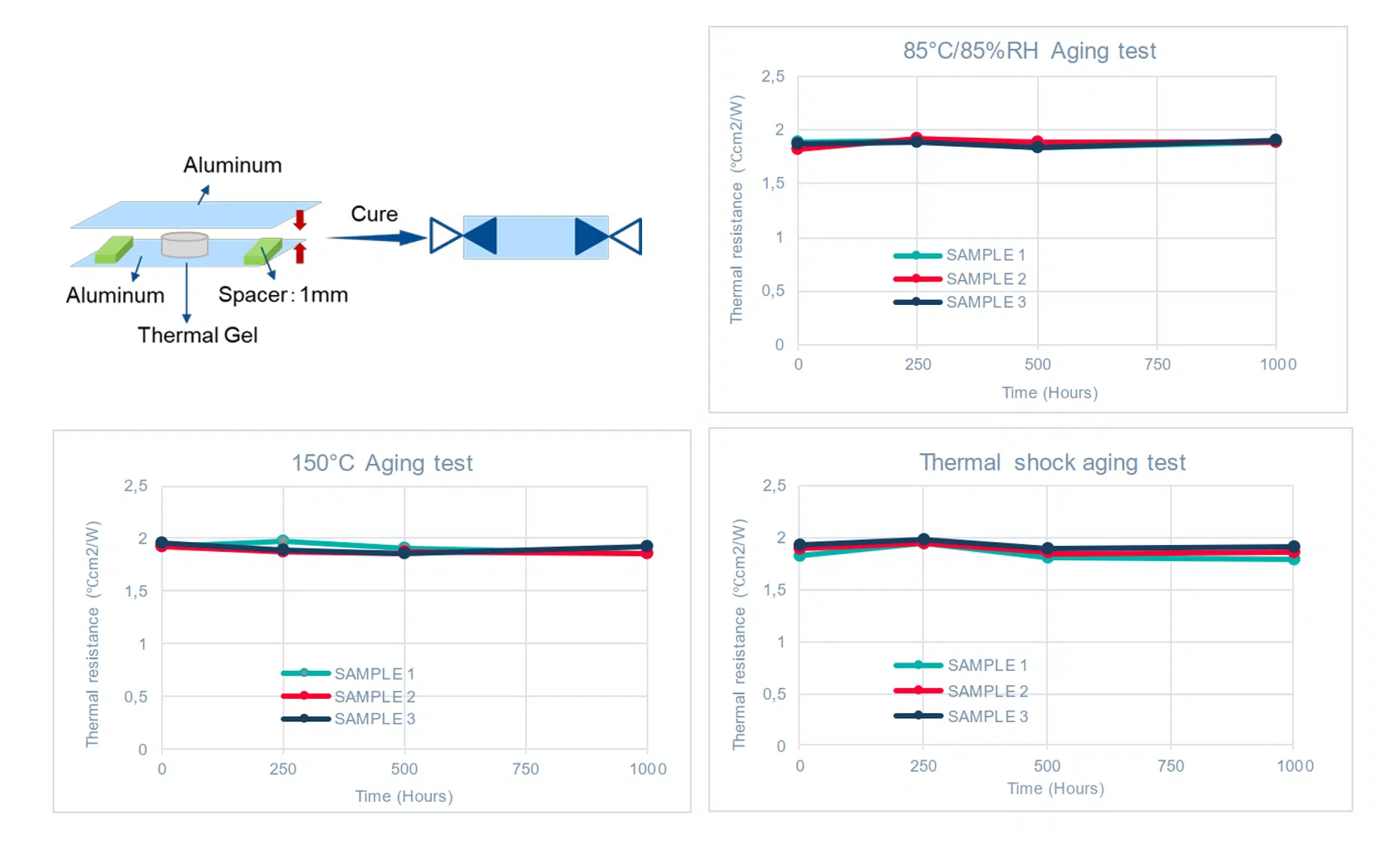

THERMAL-CONDUCTIVITY AGING

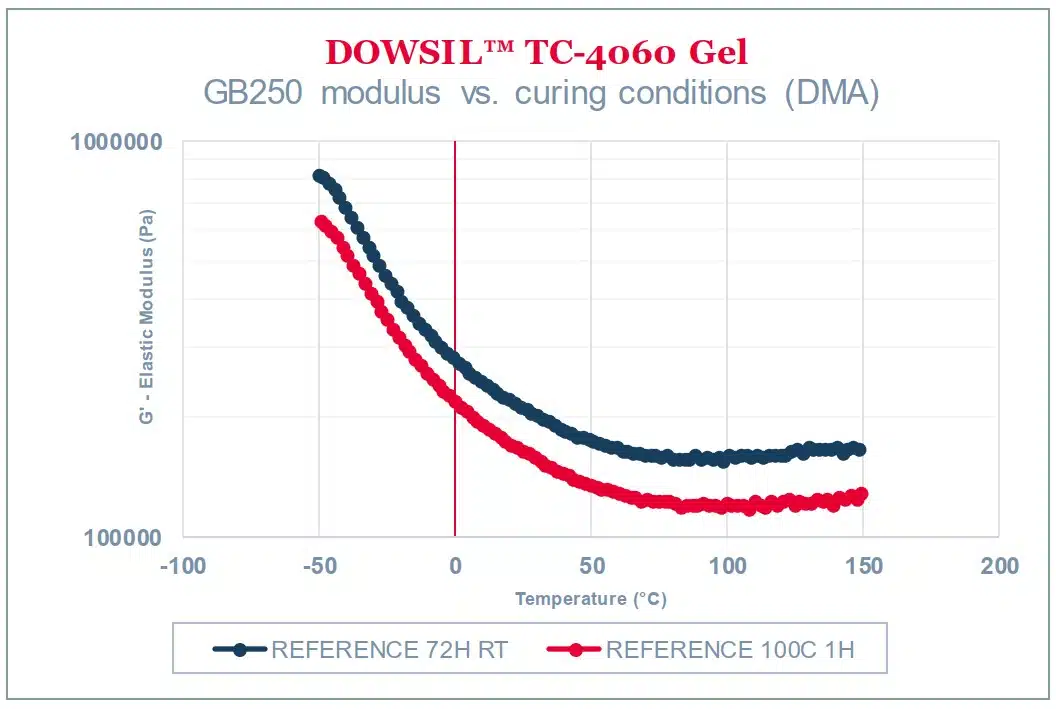

E-MODULUS BY DMA AND CTE

Dow internal test method

| CTE by TMA | Value |

| -40 to 150°C | 233 ± 59 ppm/K |

| -40 to 80°C | 201 ± 44 ppm/K |

Very minor E-modulus changes during aging test. CTE in range for thermally- conductive silicones.

More information in this video

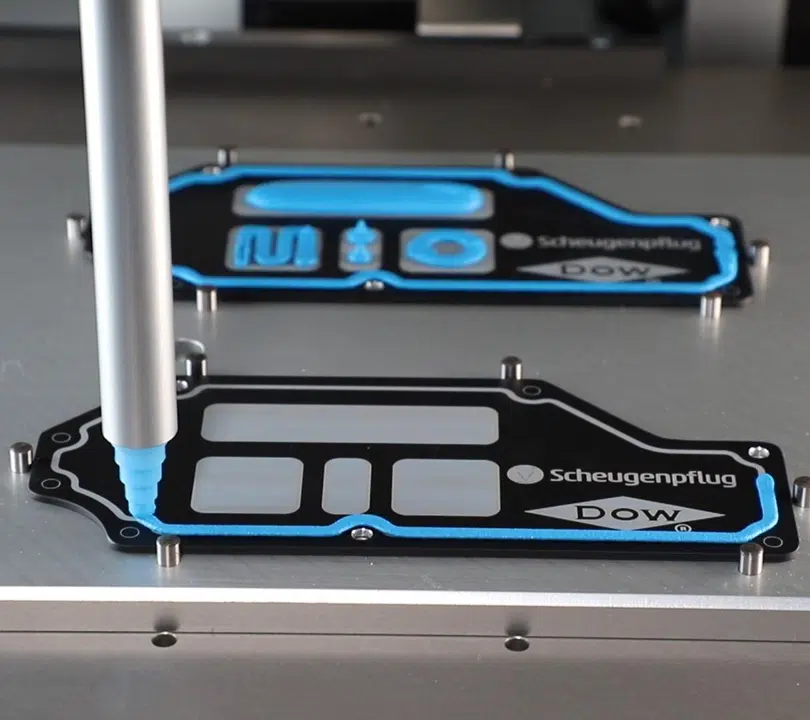

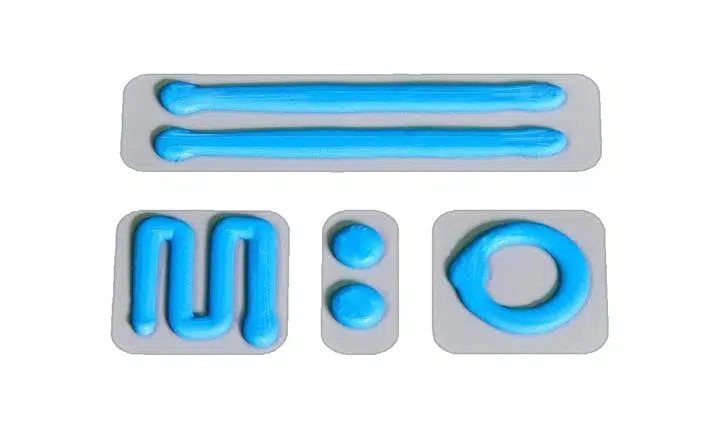

- Excellent dispensing performance at fast rate

- Dispensing speed 1.0 ml/sec

– Higher dispensing speed possible depending on machine conditions - CMK > 2.0 for 0.2 ml

- Helps reduce cycle time

- Allows intricate design geometries

Dispensing equipment (Scheugenpflugon video)

- A90 C – Compact Material Feeding System

- DosP DP803 2C/01 – Volumetric Piston Dispenser

- DispensingCell DC803 – High Performance Multifunctional Cell

Source: Dow Thermally-Conductive Composites Paper