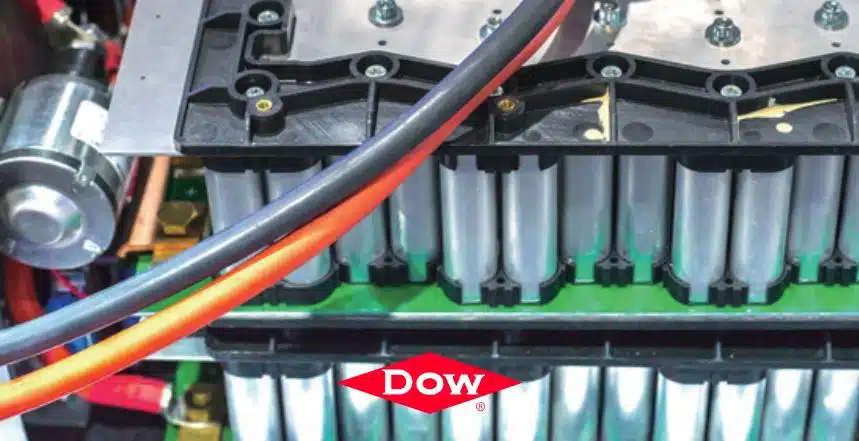

The transition to electric mobility is reshaping the automotive industry, with electric vehicle (EV) batteries at the center of this transformation. While most discussions focus on electrochemistry and lithium-ion innovations, the structural and thermal management systems within the battery pack are equally critical. High-performing adhesives and thermally conductive gap fillers provide the mechanical stability and heat regulation that modern EV batteries require. Without these materials, battery life, safety, and overall vehicle performance would be at risk.

Dow, one of DGE’s brands, through its MobilityScience™ platform, has developed the VORATRON™ portfolio of polyurethane systems, offering adhesives and gap fillers designed specifically for next-generation EV batteries. These technologies address the dual challenges of structural bonding and thermal management, enabling the automotive industry to move toward safer, lighter, and more efficient battery designs.

Advancements in EV Battery Assembly

EV battery architecture has evolved rapidly over the past decade. Early designs relied on cell-to-cell bonding, where individual lithium-ion cells were connected and stabilized within a module. As energy density and performance requirements increased, manufacturers adopted cell-to-module and later cell-to-pack designs, which reduce weight and improve integration efficiency.

The next step, already under exploration, is cell-to-chassis bonding. In this configuration, the battery is not just a power source but a structural component of the vehicle itself, integrated into the chassis. This approach reduces redundant weight, increases rigidity, and maximizes energy efficiency. However, it also places extreme demands on adhesives, which must withstand mechanical stress, vibration, and thermal cycling over the lifetime of the vehicle.

Here, polyurethane adhesives and gap fillers provide a crucial foundation. They ensure strong, long-lasting bonds and stable thermal management, allowing EV manufacturers to push design boundaries without compromising safety or durability.

High-Performance Battery Adhesives

VORATRON™ MA 8200 Series

The VORATRON™ MA 8200 Series represents a breakthrough in polyurethane-based battery adhesives. These systems are engineered to provide outstanding bonding strength for virtually any type of EV battery design, whether cell-to-cell, cell-to-module, or cell-to-pack.

Key technical advantages include:

- Exceptional bonding strength: cross tensile strength above 10 MPa on aluminum-to-aluminum and PET-to-PET substrates. This ensures reliability under mechanical stress and harsh operating environments.

- Customizable thermal conductivity: ranging from 0.3 to 2.0 W/mK, adhesives can be tuned to balance heat dissipation with mechanical stability.

- Flexibility and elasticity: systems can achieve up to 90% elongation at break, making them highly resistant to vibration and mechanical fatigue.

- Durability in harsh conditions: performance remains stable even after prolonged exposure to humidity, temperature fluctuations, and mechanical stress

Optimized for Assembly and Manufacturing

The MA 8200 adhesives are two-part, room-temperature curing systems, which simplifies production and ensures consistent quality. Their optimized rheokinetics enable smooth application during assembly, while low-abrasion properties reduce wear on dispensing equipment, cutting maintenance costs and downtime.

For manufacturers, these features translate into:

- Faster and safer assembly processes.

- Lower equipment wear and improved uptime.

- Reliable adhesion across different substrates and configurations.

This combination of strength, adaptability, and manufacturability positions polyurethane adhesives as essential components of modern lithium-ion battery packs.

Gap Fillers for Thermal Management

The Role of Gap Fillers

As EV batteries achieve higher energy density, effective thermal management becomes increasingly vital. Excess heat can cause cell degradation, reduced performance, or in worst cases, safety risks such as thermal runaway. To counter this, thermally conductive gap fillers are used to attach battery cells to cooling plates, creating a pathway for efficient heat dissipation.

VORATRON™ GF-1000 and GFA Series

Dow’s VORATRON™ GF-1000 and GFA Series gap fillers provide high-performance thermal conductivity combined with easy processing and assembly line efficiency.

Performance highlights include:

- Thermal conductivity up to 3.1 W/mK, ensuring rapid heat transfer from cells to cooling plates.

- Low squeeze force (<120 N), minimizing stress during assembly and enabling low-energy manufacturing processes.

- Shear-thinning rheology, which improves dispensing accuracy, prevents air entrapment, and ensures complete coverage.

- Mechanical balance: Hardness between 75–85 for durability, paired with elongation values up to 60% for flexibility.

The GF-1002 formulation, for example, is specifically engineered for low-energy battery pack assembly. Its shear-thinning, non-self-leveling behavior allows for precise application without introducing mechanical stress or defects in the final product.

Meanwhile, the GFA Series supports cell-to-pack (CTP) designs, offering adjustable adhesion and stiffness when bonding to aluminum or PET. This tunability ensures that EV manufacturers can optimize both thermal performance and structural integrity depending on pack design.

Customizable Solutions for EV Battery Design

One of the defining advantages of the VORATRON™ systems is their customizability. By adjusting the filler content, density, and conductivity, manufacturers can fine-tune adhesives and gap fillers to match the specific demands of different EV platforms.

Benefits of customization include:

- Lightweight designs: low-density polyurethane reduces overall battery weight, extending vehicle range and efficiency.

- Vibration resistance: tailored toughness and elasticity minimize mechanical stress, prolonging battery lifespan.

- Enhanced safety: strong bonding and heat dissipation reduce the risk of thermal runaway and ensure stable operation.

- Sustainability: by improving durability and efficiency, these systems contribute to longer battery life cycles and reduced material waste.

This adaptability makes the VORATRON™ portfolio not just a set of products, but a toolkit for next-generation EV battery engineering.

What role do polyurethane systems play in extending the lifespan of EV batteries?

Polyurethane systems like VORATRON™ adhesives and gap fillers extend EV battery lifespan by ensuring durable structural bonding and effective thermal management. Strong adhesion prevents mechanical failures, while tunable thermal conductivity and vibration resistance protect cells from stress and overheating, keeping batteries reliable over time

How can adhesives improve vibration resistance in electric vehicle battery packs?

Adhesives such as the VORATRON™ MA 8200 Series provide toughness and elasticity. This flexibility allows them to absorb and reduce vibrations, minimizing stress on cells and modules. By maintaining structural integrity under constant motion, they protect sensitive battery components from fatigue and premature wear

Why is low abrasion important in adhesive systems for EV battery manufacturing?

Low abrasion in adhesives is crucial because it reduces wear and tear on dispensing equipment used in high-volume EV battery production. VORATRON™ systems are designed with low-abrasion fillers, which help extend equipment lifespan, lower maintenance costs, and ensure consistent adhesive application throughout the assembly process

Stronger, Safer, Smarter EV Batteries

The future of electric mobility depends both on advances in cell chemistry and on the supporting technologies that keep EV batteries safe, efficient, and reliable. Adhesives and gap fillers may not be visible to drivers, but they are fundamental to the performance of every electric vehicle on the road.

Dow’s VORATRON™ polyurethane systems demonstrate how material science innovation addresses the structural and thermal challenges of EV batteries. With bonding strengths above 10 MPa, thermal conductivity up to 3.1 W/mK, and customizable mechanical properties, these systems enable robust cell-to-pack and future cell-to-chassis designs.

By combining structural bonding, thermal management, and manufacturing efficiency, adhesives and gap fillers are helping EV manufacturers deliver vehicles that are lighter, safer, and more sustainable. As EV adoption accelerates, these advanced materials will remain indispensable to the evolution of electric vehicle battery technology.