MOLYKOTE® has been collaborating with customers to gain a deep understanding of their specific applications and the underlying causes of their lubrication difficulties.

In order to meet the performance requirements set by a vehicle Original Equipment Manufacturer (OEM) client, a strain-wave gear technology manufacturer required a superior lubricant that would surpass the capabilities of existing grease options based on Polyalphaolefin (PAO). Important factors in selecting the lubricant included its ability to reduce noise, provide effective lubrication under high-pressure sliding friction, perform well in low temperatures, offer suitable grease mobility, and be compatible with the gearbox elastomer seals.

By conducting tests and working closely together, they were able to assist the manufacturer in enhancing performance for their customer. Here are the details of the case study:

Application

A backlash-free, high-reduction strain-wave gearbox for an active stabilizer suspension system being used on select models of a luxury-class vehicle brand.

Faster-acting than typical hydraulically actuated roll stabilizers, the advanced electromechanical design incorporates a strain-wave gearbox, specially developed brushless motor and an electronic controller to influence torque coupling and dramatically reduce rolling movements of the vehicle.

Challenge

To meet a vehicle OEM customer’s performance specifications, the manufacturer of the strain-wave gear technology needed an effective lubricant to outperform current PAO-based grease options. Key lubrication criteria included noise-damping capabilities, good lubricity with high-pressure sliding friction, good low-temperature performance, suitable grease mobility, and compatibility with gearbox elastomer seals.

Solution

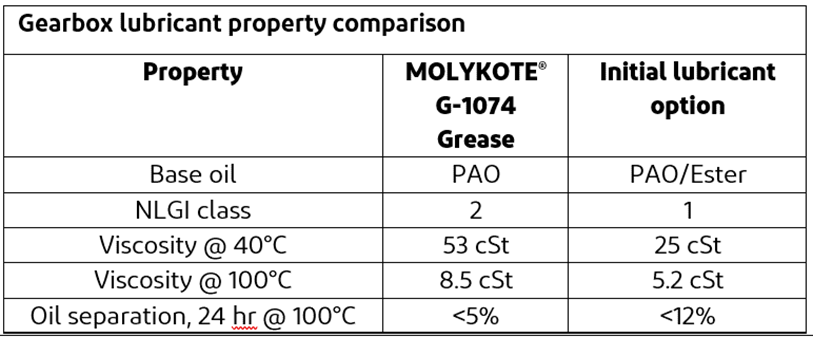

The manufacturer collaborated with MOLYKOTE® application engineering specialists to identify an effective solution to meet the gearbox lubrication needs. Compared with an initial PAO/ester grease for gearbox lubrication, MOLYKOTE® G-1074 Grease delivered superior performance.

The performance properties of MOLYKOTE® G-1074 Grease compare favorably with those of the initial lubricant option for the gearbox application.

Potential advantages of MOLYKOTE® G-1074 Grease include:

- Better noise-reduction capabilities

- Reduced friction under extreme pressure at high frequency

- Less oil separation

- Better oxidation stability

- Good lubricity over a wide service-temperature range

- Excellent compatibility with H-NBR sealing elastomers

Based on gearbox lubrication performance in the vehicle active suspension system, the manufacturer expects to qualify MOLYKOTE® G-1074 Grease for use in other actuator applications for robotics, farm machinery, autonomous vehicles, industrial control technologies and more. Based on industry interest, mechatronic roll stabilizer applications have sizable growth potential across multiple vehicle platforms.