Increasingly, industry trends demand small components with higher power densities. These trends require a reliance on stronger gels that protect assemblies and their properties. DOWSIL™ EG-4XXX Dielectric high temperature gels are silicone dielectric gels suitable for potting and protecting devices, especially in PCB and power modules to protect the dies and interconnects from environmental conditions and to provide dielectric insulation.

The EG-4XXX series provides:

- Protection for interconnections subject to thermal and mechanical stresses

- Stability under harsh environmental conditions

- No surface cracking or delamination from housing within a large temperature range

Dow two-part EG-4XXX high temperature gels are suitable for operating temperature ranging from -40C to + 215℃ allowing devices to operate at these extreme temperatures. The soft nature of these gels can assist in managing the CTE mismatch between components or materials during such low and high temperature excursions. This high temperature performance could assist in lowering field failures and warranty costs.

Gels are a special class of encapsulants that cure to an extremely soft material. Gels cure in place to form cushioning, self-healing, resilient materials. Cured gels retain much of the stress relief and self-healing qualities of a liquid while providing the dimensional stability of an elastomer which is increasingly needed for delicate components. Gels have been used to isolate circuits from the harmful effects of moisture and other contaminants and provide electrical insulation for high voltages.

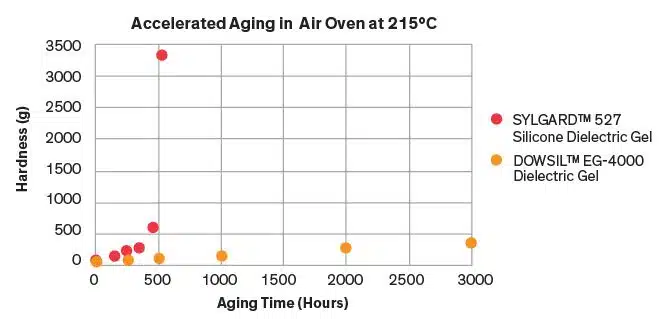

Another use is providing stress relief to protect circuits and interconnections from thermal and mechanical stresses. Gels are usually applied in thick layers to totally encapsulate higher architectures. This high temperature resistant gel has been demonstrated to operate efficiently for more than 3,000 hours at 215°C, without cracking, delamination, electrical failure or formation of void in the material. This ensures proper usage at a continuous temperature of 200°C per UL-1557 standard.

The Dow high temperature EG-4XXX product family consist of:

1- DOWSIL™ EG-4000 Soft High Temperature Resistant Gel: 2-parts, Heat Cure Silicone Gel With Enhanced Thermal Resistance

DOWSIL™ EG-4000 is a very soft gel for thin layer application (up to 2mm) where high stress release is required

This Dielectric Gel is a two-parts, heat-cure, dielectric silicone material that delivers outstanding thermal stability over a broad temperature range up to 200°C in continuous mode (validated by accelerated aging at 215°C for 3000 hours according to UL-1557 standard). The chemistry has been engineered in order to also expand the lower temperature limit resistance to -60°C to meet market specific requirements.

The extremely low modulus of this advanced silicone gel also minimizes stress on very stress-sensitive system components resulting from thermal cycling, impact and vibration. These properties enable DOWSIL™ EG-4000 Gel to deliver long-lasting performance as a protective potting material for power conversion applications, such as insulated gate bipolar transistor (IGBT) modules used in power electronics.

Its unique combination of thermal stability and extremely low modulus also make it an appealing solution for automotive PCB system assemblies, sensors and actuators that must operate reliably over large temperature ranges and when highly stress sensitive components are present.

Potential Uses

Potting material for automotive stress-sensitive PCB, power conversion and other modules that must operate reliably over a broad temperature range up to 200°C in continuous mode.

Key Features:

- Excellent thermal stability up to 215°C for 3000 hours

- Suited for continuous operation of power modules at 200°C

- Reliable protection against damaging environmental conditions

- Very efficient mechanical stress release buffer layer

- Reliable dielectric insulation

- Extremely soft material for highly stress sensitive device protection

Benefits:

- Reliability of devices used in extreme temperature conditions

- Protect wires, ribbons and delicate leads against thermal cycling, impact, dust and vibrations

Typical Applications:

- Potting of IGBT modules used for power conversion

- Protection of PCB and sensitive devices operated at high temperature

- Industrial sensors and actuators

- Insulation of high voltage devices

Application Method:

- Automated or manual needle dispensing methods

2- DOWSIL™ EG-4100 and DOWSIL™ EG-4120: tougher gels for applications where thicker silicone (up to 30mm) gel is applied

DOWSIL™ Tough High Temperature Resistant Gels: DOWSIL™ EG-4100 and EG-4120 Dielectric Gels 2-parts, Heat Cure Silicone Gel With Enhanced Thermal Resistance

DOWSIL™ EG-4100 and EG-4120 Dielectric Gel are two-parts, heat-cure, dielectric silicone material that delivers outstanding thermal stability over a broad temperature range up to 200°C in continuous mode (validated by accelerated aging at 215°C for 3000 hours according to UL-1557 standard).

The low modulus of this advanced silicone gel also minimizes stress on delicate system components resulting from thermal cycling, impact and vibration. These properties enable DOWSIL™ EG-4100 and EG-4120 Gels to deliver long-lasting performance as a protective potting material for power conversion applications, such as insulated gate bipolar transistor (IGBT) modules used in power electronics. Its unique combination of thermal stability and low modulus also make it an appealing solution for automotive PCB system assemblies, sensors and actuators that must operate reliably over large temperature ranges.

These gels have been formulated to improve the resistance to delamination from the housing or the substrate when thermal aging is performed for an extended period of time (up to 3,000 hours at 215°C) to protect the devices against partial discharge and dielectric failure events.

Potential Uses

Potting material for power conversion and other modules that must operate reliably over a broad temperature range up to 200°C in continuous mode.

Key Features:

- Excellent thermal stability up to 215°C for 3000 hours

- Suited for continuous operation of power modules at 200°C

- Reliable protection against damaging environmental conditions

- Very efficient mechanical stress release buffer layer

- Reliable dielectric insulation

- Primerless adhesion to avoid delamination under thermal cycling

Benefits:

- Reliability of devices used in extreme temperature conditions

- Protect wires, ribbons and delicate leads against thermal cycling, impact, dust and vibrations

Typical Applications:

- Potting of IGBT modules used for power conversion

- Protection of PCB and sensitive devices operated at high temperature

- Industrial sensors and actuators

- Insulation of high voltage devices

Application Method:

- Automated or manual needle dispensing methods