Are you trying to meet the demands of 5G technology, such as the demand for strong thermal conductivity? 5G designs require greater power densities, which produce greater heat. Technology with such high temperature output requires materials that help dissipate the heat, materials like DOWSIL™ TC-4040 Dispensable Thermal Pad.

DOWSIL TC-4040 Dispensable Thermal Pad

DOWSIL™ TC-4040 Thermal Pad is a two-part thermal interface material (TIM) and gap filler that is easy to dispense and provides strong thermal conductivity. This material increases assembly efficiency by allowing for either room temperature or accelerated curing as well as vertical assembly before curing because of its excellent slump resistance.

Thus, DOWSIL™ TC-4040 Dispensable Thermal Pad not only enables your 5G technology to function but optimizes the process by which that technology is assembled.

Market Needs

High thermal dispassion, easy to assembly, High Reliability, Good vertical slump resistance

Value Proposition

DOWSIL TC-4040 Dispensable Thermal Pad provides excellent balance among thermal management and process-ability for high power thermal management applications (5G base station, power module, control unit, etc…)

DOWSIL TC-4040 Dispensable Thermal Pad provides excellent balance among thermal management and process-ability for high power thermal management applications (5G base station, power module, control unit, etc…)

Key Benefits

Excellent Thermal MGNT: Good wetting performance than Fabricated pad

High Reliability: Stable thermal and Mechanical properties after aging

High Efficient Process-ability and Process Reliability

- High extrusion rate for high efficiency and easy process

- Stable thermal and mechanical performance after HT and TS Aging

- Good vertical slumping resistance

DOWSIL TC-4040 Key features And Benefits

- 4W/mk Thermal Conductivity: Improved high power device heat dissipation and thermal management.

- Stable Thermal performance at 150°C, 85oC/85%RH and -40oC to 125°C Thermal shock: Provided long-term thermal reliability. Improved devices thermal and mechanical duration under severe conditions.

- Stable mechanical performance at 150 and 175°C/1200hours aging: Kept stable gap filling performance and remained reliable stress absorbing and releasing performance at high temperature.

- 350g/min extrusion rate and Thixotropic index 4.9: High extrusion rate to lead high efficient dispensing. No flowing after dispensing. Reliable assembly process.Reliable for wide gap applications from 130µm to 3mm.

- Vertical stability up to 3mm Gap: Provided good gap filling reliability when using. Met Both flat and vertical applications.

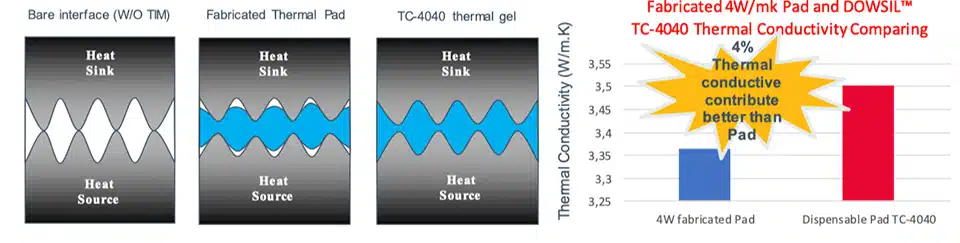

Lower contact resistance

Flowable matrix had: better wettability, better filling micro gaps and reducing contact resistance better than fabricated pads, films. This resulted in lower thermal resistance and better thermal performance.

Using ASTM D5470 method, comparing thermal conductive performance between 4W/ mk fabricated Pad and DOWSIL™ TC-4040, we can see:

- Both are 4W/mk, but DOWSIL™ TC-4040 showed about 4% higher as better voids filling ability.

- Compare to delta T, it could lead to about 0.5-1.0oC difference at 60W power.

DOWSIL TC-4040 – Rheology Property

Higher Thixotropic nature provides:

- Higher extrusion rate when higher shearing rate, and resulted in a high throughput

- Stay in place (no flow) once dispensed for a good accuracy shape of the patterns.

Testing Process and Conditions:

- Cure at 25°C for 24 h.

- Put cured DOWSIL™ TC-4040 material under -40C/30min to 125C/30min thermal shock for 1000hours.

- Measure thermal conductivity, hardness, dielectric strength per 200hours

DOWSIL™ TC-4040 had Stable thermal conductivity, hardness, dielectric strength performance after 1000hours thermal shock aging.