Lighting Market and its Challenges

Stick to the Clear Advantage.

Growth and Impact on the Planet

Global LED lighting market to reach $100B in the upcoming decade. This corresponds to 12%+ CAGR in value and 20%+ CAGR in volume

Lighting related energy consumption is expected to drop by 40% in 2030, thanks to LED penetration into general illumination.

Addressing the Needs of Professional Lighting Market

The professional LED lighting market is expected to surpass $35B by 2022. This includes industrial, commercial, outdoor, and architectural applications.

Main growth drivers are linked to the expectations of:

- High efficiency

- Reliability and robustness

- High brightness

- Condensed size and customized shapes

- Low power consumption

The Need for High Ingress Protection

- Flexible and Rigid LED Strips

- Outdoor LED Displays

- Explosion Proof Lighting

- Linear: Tube and string/strip

- Spot, flood and general-area

- Small portable-type: Flashlights, wearable headlamp

- Specialty and panel

Protective Materials Over LEDs

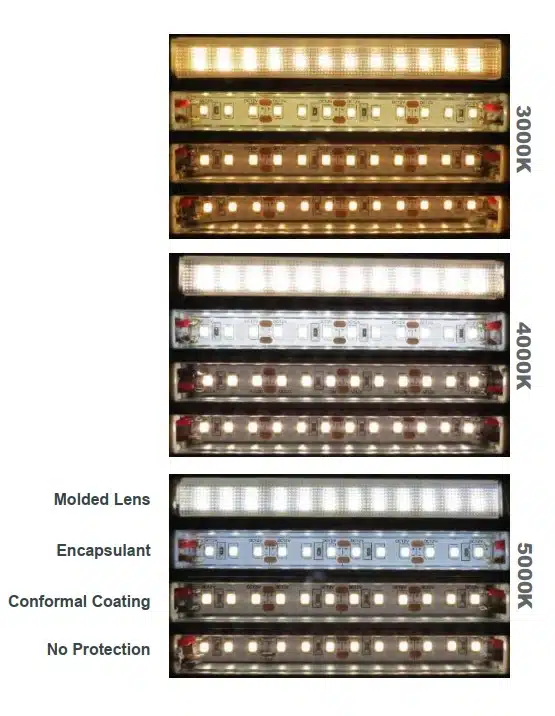

Protection options

Conformal Coating

- Minimally effects luminous flux and CCT

- Challenge: Provides the least amount of protection above bare components

Optical Encapsulant

- Provides the highest degree of protection and ease of use

- Challenge: Impact on CCT

Molded Lens

- Best optical management

- Challenge: Lower degree of protection (air gap) and more complex impacting price

Encapsulation is best suited for harsh environments, such as explosion proof or high IP rated luminaires.

Protection and performance

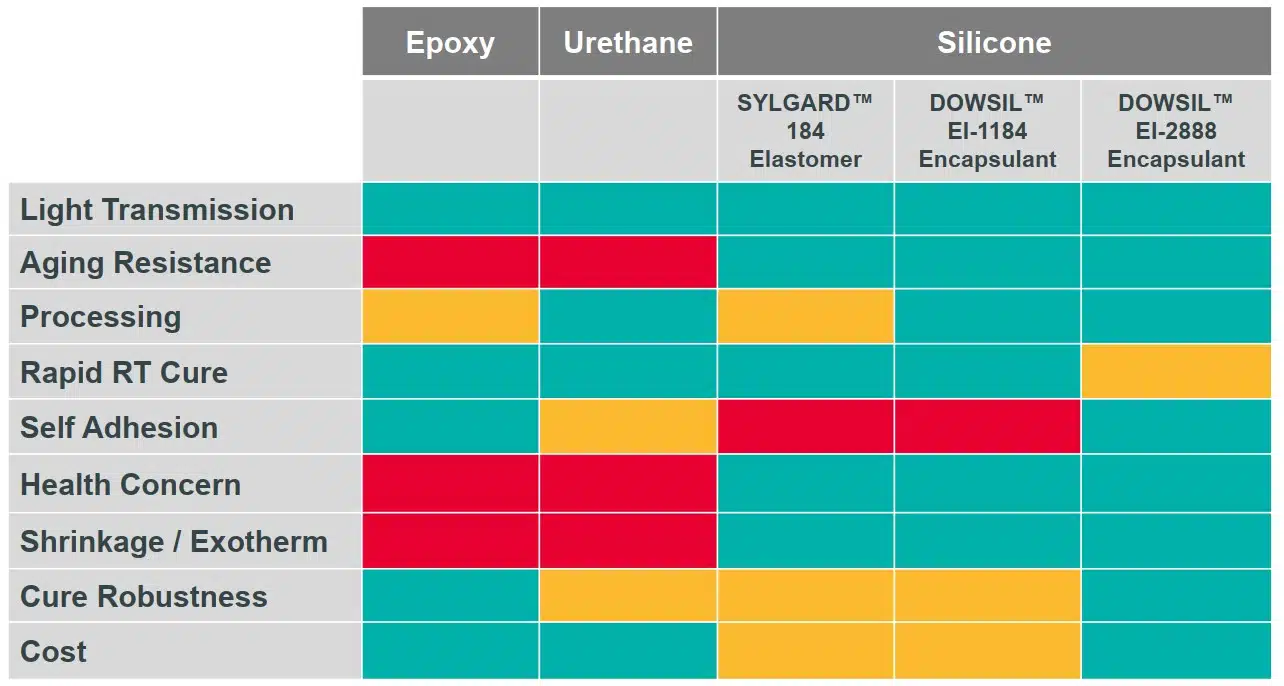

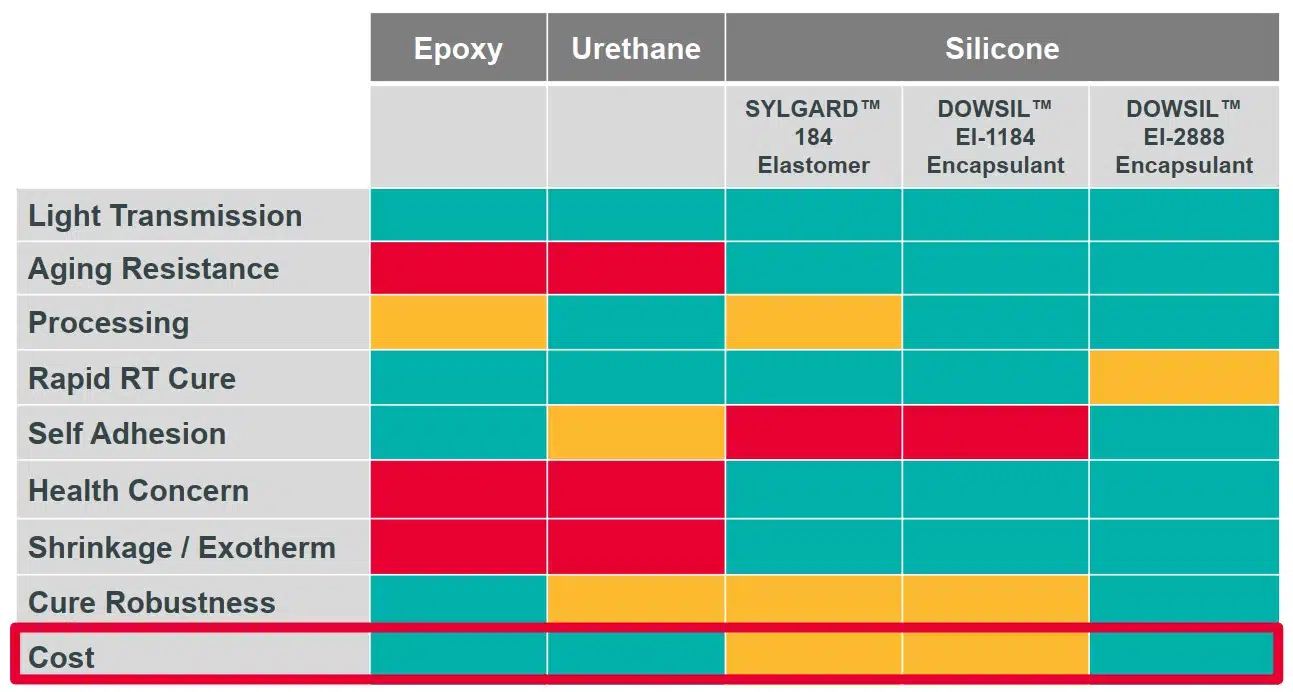

DOWSIL™ EI-2888 Encapsulant versus other solutions.

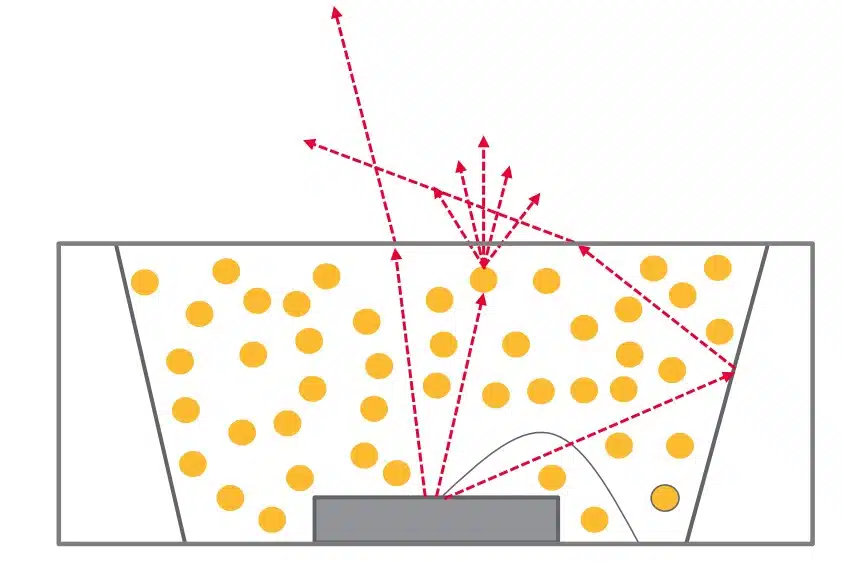

Optical influence

Protective material can:

- Change Fresnel reflection

- Change color converted light

- Change total internal reflection

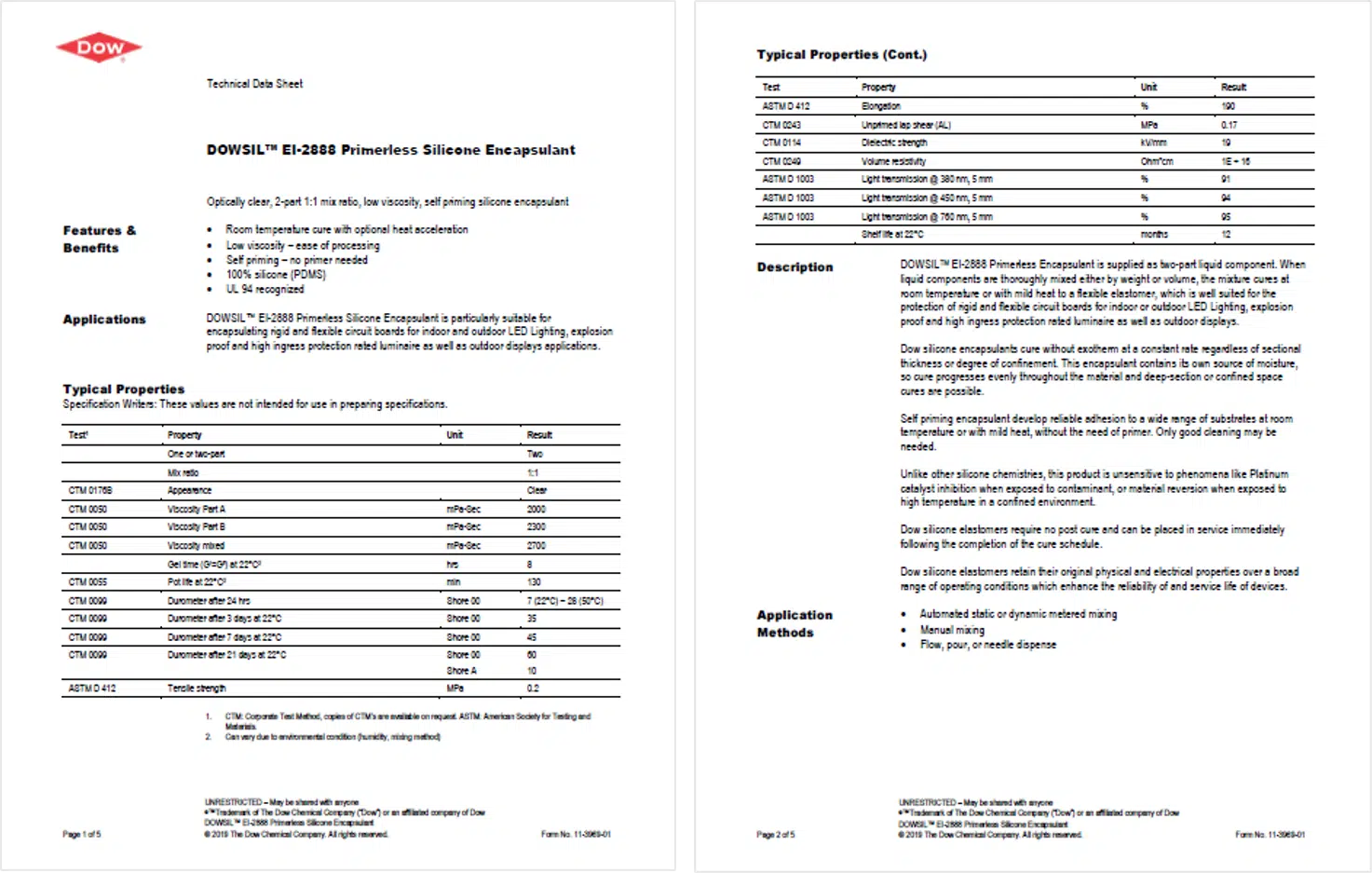

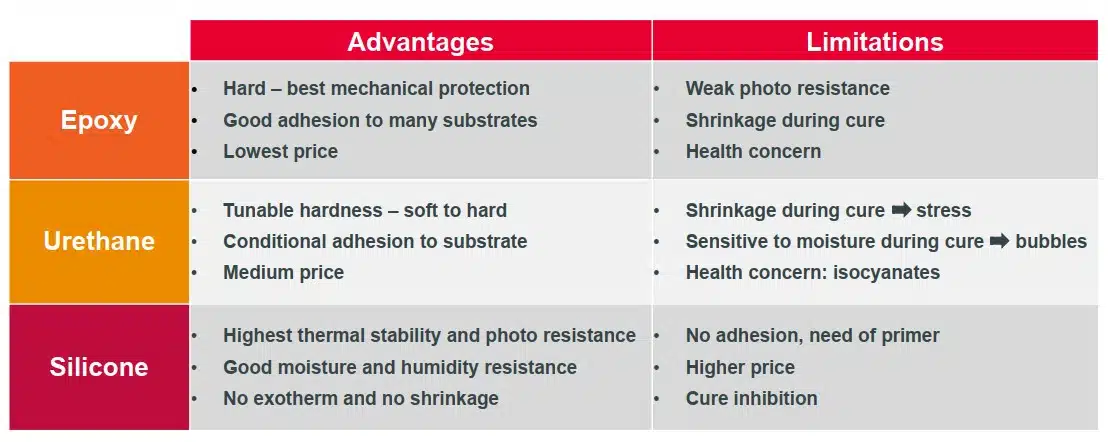

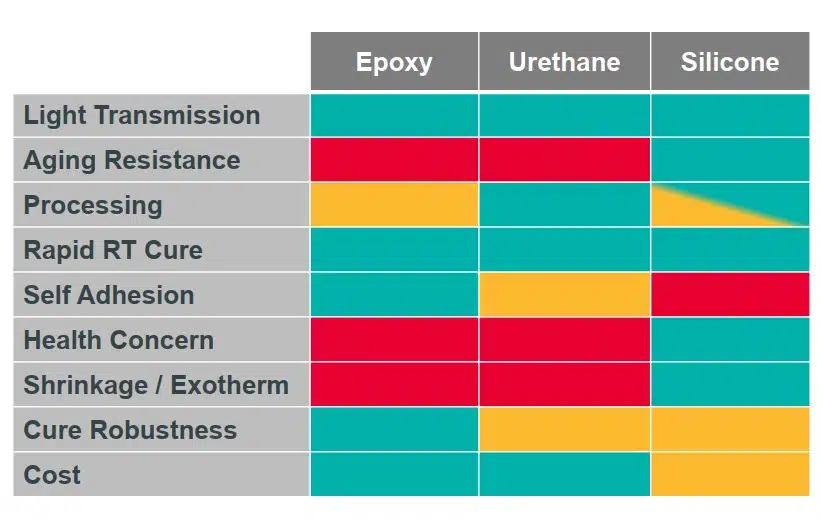

Existing Encapsulation Materials

Innovate with DOWSIL™ EI-2888 Primerless Silicone Encapsulant

![]()

Innovative Technology from Dow

- Patented technology

- 100% silicone product

![]()

![]()

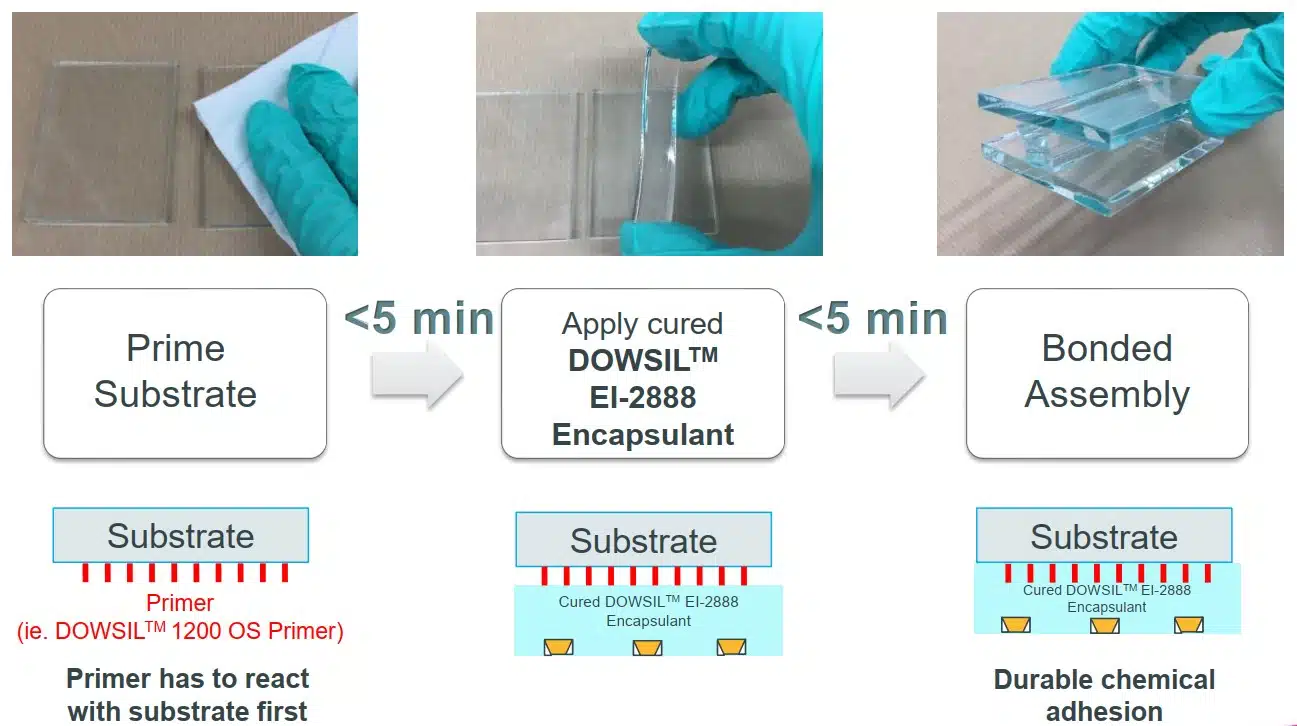

Self Adhesive

Reliable adhesion on:

- Anodized aluminum

- Glass

- FR4

- Stainless steel

- Steel

- Polycarbonate

- PBT

- Copper

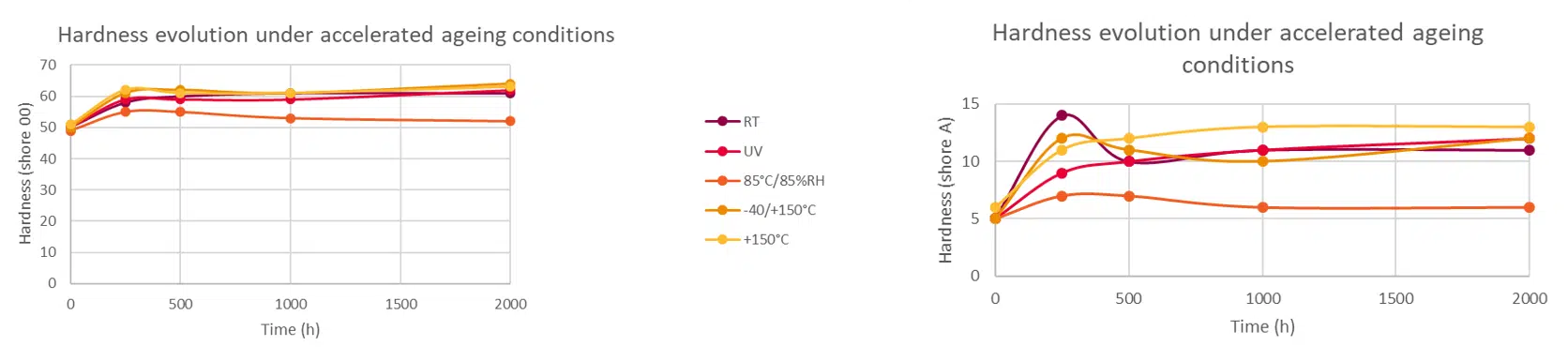

Even after 2000 hours exposed to:

- 150ºC

- 85ºC / 85% RH

- -40 / +150ºC thermal shock

- Sunlight UV

Limitation: PMMA, die-cast aluminum

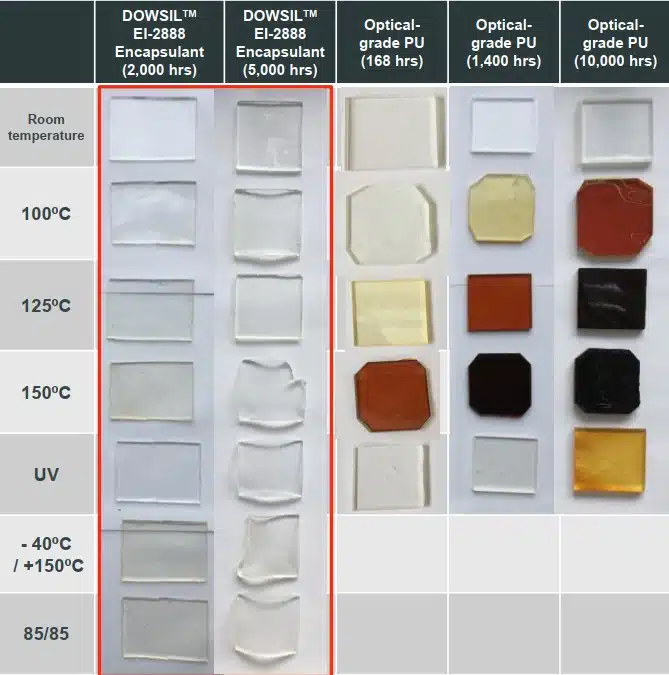

Optically Clear Under Harsh Environment

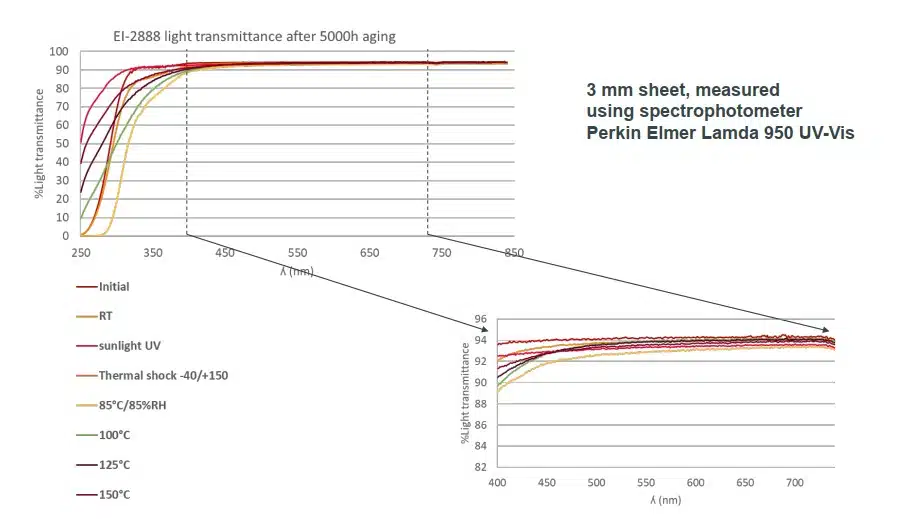

Optically Stable Beyond Visible Range and Under Aging

Proven Results

Two rigid, high-power LED modules using DOWSIL™ EI-2888 Encapsulant

Cure Robustness

- Not subjected to cure poisoning

- Common issue with silicone-based encapsulants

- Not sensitive to moisture during cure ≠ urethane

- No need for control atmosphere

- Lower cleaning requirement

Potential cost saving

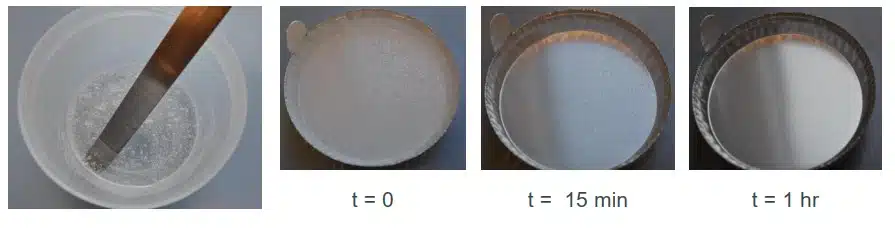

Ease of De-gassing

- Suitable with various mixing techniques, such as hand stirring,

static mixing, dynamic mixing, and by centrifuge - No need for vacuum after application

Low viscosity

| Part A | 2,000 mPa.s |

| Part B | 2,300 mPa.s |

| Mixed | 2,700 mPa.s |

1:1 Mix ratio

Flexible and Robust

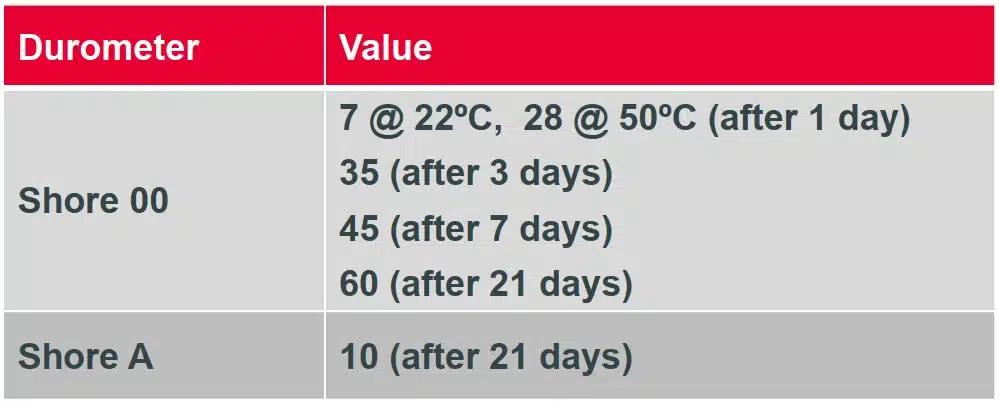

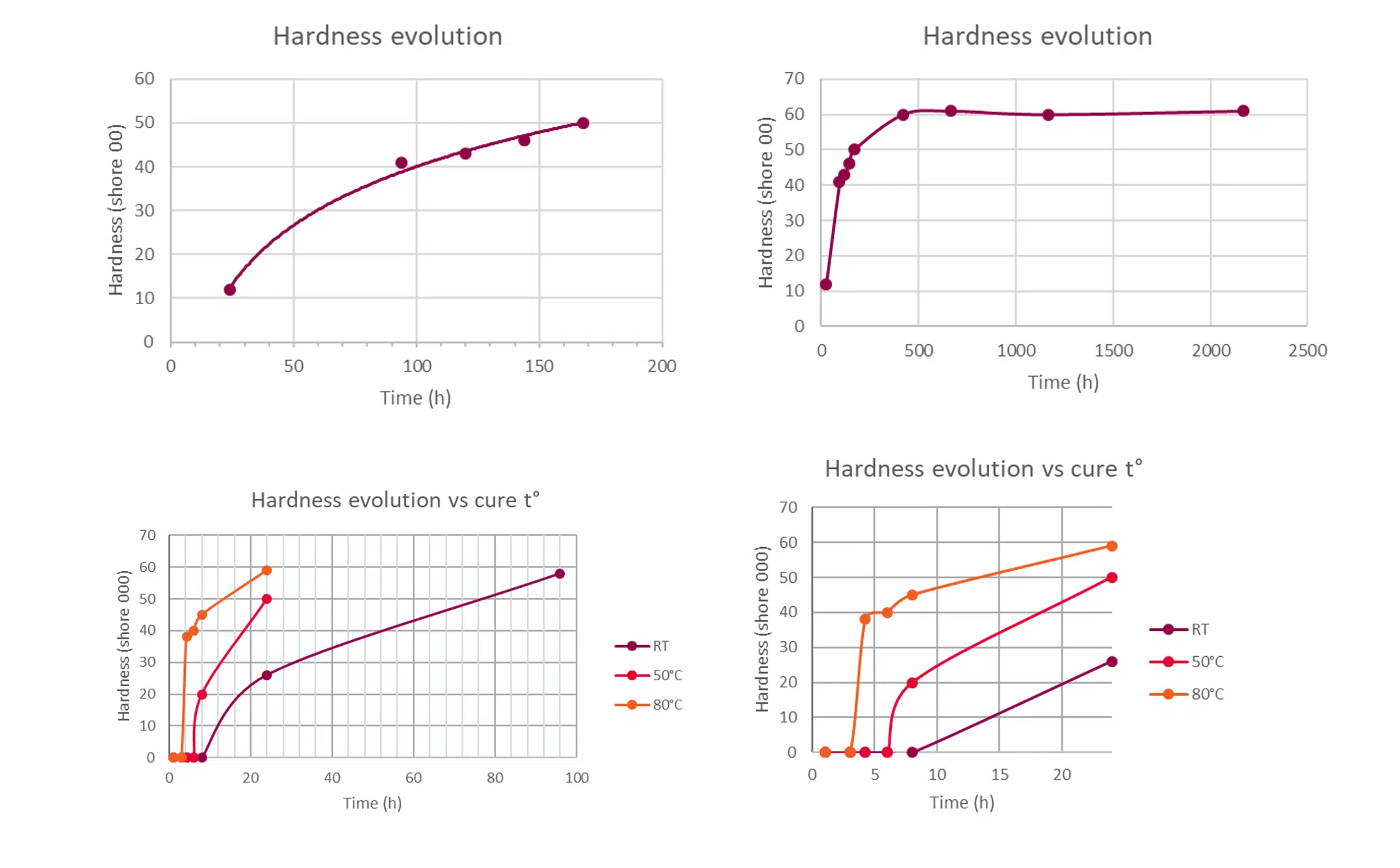

Cure Time / Hardness to Design Your Process

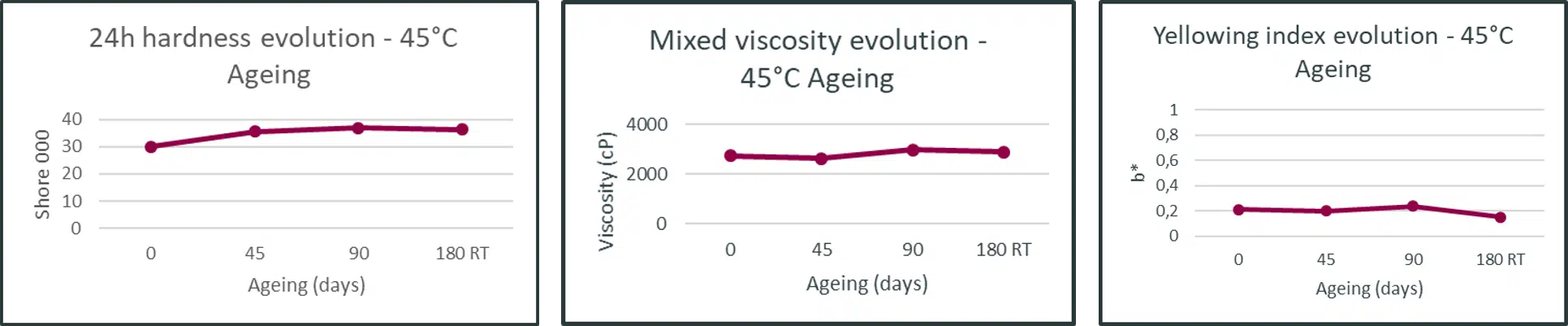

Stable Under Aging

Good Dielectrical Properties

| Property | Value |

| Dielectric strength | 19kV/mm |

| Volume resistivity | 1E+16 Ω.cm |

| Surface resistivity | 2,6E+14 Ω • |

Long Usable Life

- One-year stability expected

- Keep packaging closed − avoid moisture

- Moisture contamination will decrease cure speed

Additional Unique Feature

Final Comparison / Recap

Price Positioning

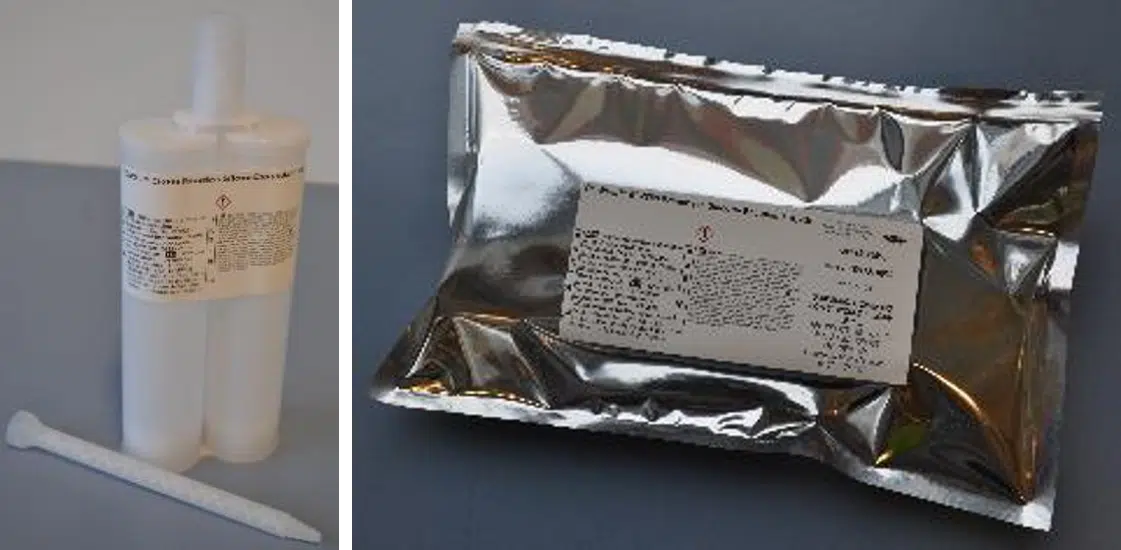

Packaging

Sample

- 400 ml side-by-side CRT

- Material number:

- 400 ml A/B kit: 99124556

Standard

- 2 x 19 kg Jerry can

- 2 x 200 kg drum

- Material number:

- 19kg: 99120811 (Part A) 99117550 (Part B)

- 200kg: 99120810 (Part A) 99117489 (Part B)

Technical and Safety Data Sheets Available