IMAGINE improved thermal conductivity – easier processing and long-term performance stability

DESCRIPTION

DOWSIL™ thermally conductive gap fillers are soft, compressible, two-part, high-thermalconductivity silicone materials specifically formulated to process easily and to effectively dissipate heat away from PCB system assemblies such as printed circuits by conducting it to a heat sink such as an aluminum housing.

The softness, tackiness and compressibility of gap fillers compensate for nonsystematic flatness tolerances of the PCB and the heat sink. These intrinsic properties allow efficient interface contact to be maintained, improving heat transfer. Gap fillers also dampen vibration effectively, reducing the risk of failure caused by mechanical vibration.

KEY FEATURES

- Holds vertical position (cured or uncured)

- UL 94 V-0 certification

- Glass bead option (180 micron) for bondline thickness (BLT) control

APPLICATION NOTES

- Enhanced processing experience thanks to ease of dispensing and assembly

- Ideally suited for automated dispensing with metered mixing equipment; approved by Scheugenpflug equipment supplier

POTENTIAL USES

- Thermal management and vibration damping for electronic devices

TYPICAL APPLICATIONS

- Engine control unit

- Anti-lock braking/electronic stability control – safety system

- DC/DC converter of hybrid electric vehicle (HEV)

- Advanced driver-assistance systems

- Sensors

- Transmission control unit

- Battery assembly

As automotive PCB system assemblies contribute ever-greater value to automotive safety, reliability, performance and comfort, they also are generating higher temperatures that can reduce the functionality and reliability of modules over time.

Dow offers a portfolio of thermally conductive silicone gap fillers with different levels of thermal conductivity that deliver dispensing ease and stable performance for more reliable PCB system

assemblies in harsh automotive underhood environments.

DOWSIL™ thermally conductive gap fillers are soft, compressible, two-part, highthermal-conductivity silicone materials specifically formulated to process easily and to effectively dissipate heat from critical PCB system assemblies such as engine or transmission control units, braking and stability controls, sensors, and other high-heat applications.

Advantages of Thermally Conductive Gap Fillers

These advanced thermal management solutions offer key benefits:

- Improved reliability in harsh temperatures: Thermally conductive gap fillers effectively dissipate heat away from sensitive components. They withstand peak exposure at 200°C, and they perform reliably at operating temperatures ranging up to 150°C.

- Easy processing: These advanced thermally conductive silicone gap fillers dispense easily from the original packaging with minimal to no additional process preparation, making them well-suited for automated application using standard metered mixing equipment.

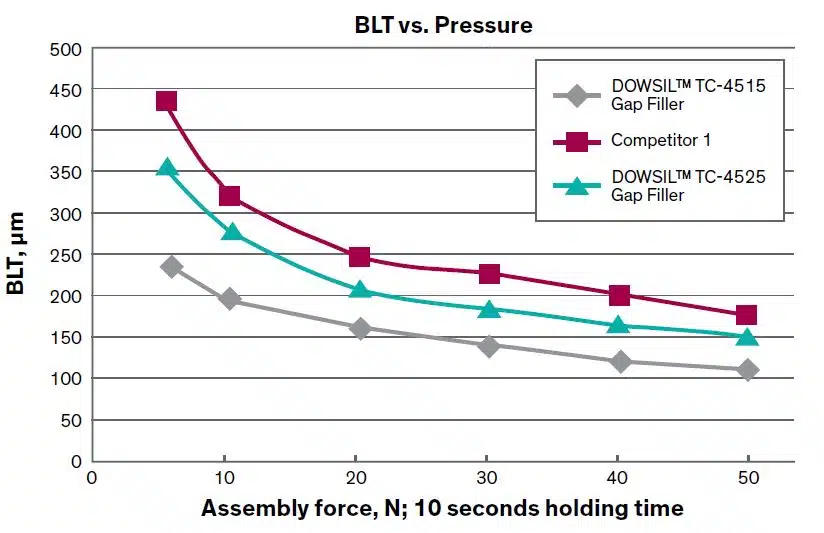

- Effective assembly: Thermally conductive gap fillers avoid slumping on vertical surfaces during assembly. After cure, they maintain their vertical stability even after long use. Select formulations incorporate glass beads to control bond line thickness (BLT) during assembly.

- Cost-effective, fast cure: The platinum cure system enables fast, controlled cure at room temperature, although cure times can be accelerated further with heat to reduce manufacturing cycle times. No post-cure steps are required.

- UL 94 V-0 recognition: Received recognition under Underwriters Laboratories’ UL 94 standard, which evaluates the flammability of plastic and silicone materials intended for parts in devices and appliances. Recognition under UL 94 is a step towards applying the UL label on your final product.

Remarkable Mechanical Stability

Excellent Spreadability at Low Pressure