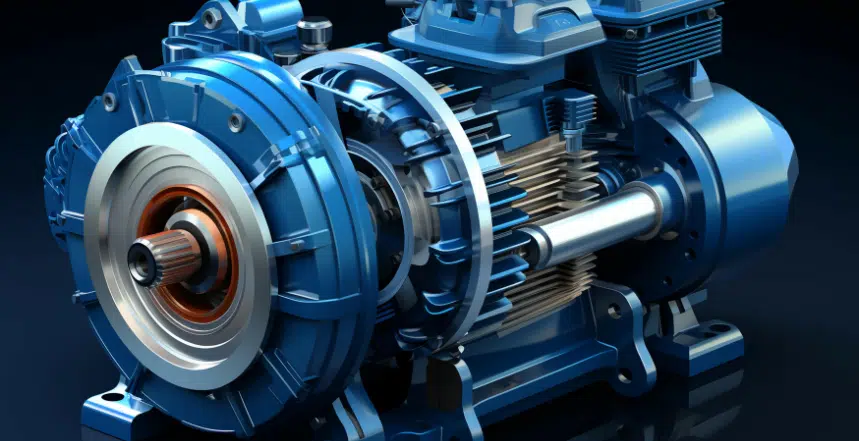

Achieving optimal performance from rubber seals exposed to aggressive fluids or gases is contingent upon the selection of superior lubrication. Rubber seals serve as indispensable components in various mechanical systems, pumps, compressors, engines, and precision equipment. They also find extensive use in sealing applications, such as automotive sunroofs.

Independently of whether a seal operates in a static or dynamic capacity, our arsenal of high-performance lubricants serves as a critical fortification, giving excellent functionality. These lubricants can be meticulously tailored to align with a seal’s operational temperature and the specific chemical environment it contends with. This inherent adaptability ensures that seals fabricated from diverse materials and intended for operation in various environmental conditions can be meticulously engineered to meet exacting performance standards.

In 2021, the global market for seals and gaskets recorded a valuation of approximately €50 billion, characterized by a projected annual growth rate of 4.1% over the ensuing decade. This surge can be attributed to the escalating utilization of advanced materials in the production of seals and gaskets, particularly for mission-critical applications in aerospace, medical instrumentation, and chemical processing. In response, manufacturers of seals confront the pressing need for innovative lubrication solutions that not only enhance operational efficiencies but also confer cost reduction advantages, thereby securing a competitive edge within this burgeoning sector.

Optimizing Rubber Seals with Specialized Lubricants

At DGE Group, we provide Molykote and Krytox high-performance lubricants; oils and greases that offer exceptionally long life and outstanding properties for the superior lubrication of rubber seals. Other benefits of using Krytox and Molykote high-performance lubricants for seal lubricant applications include:

- Ability to survive extreme temperatures and water washout

- Fully retain their properties over the life of a seal – preventing seal damage or breakage

- Non-damaging to plastic or elastomers – broad elastomeric compatibility

- Non-corrosive to metals

- Non-oxidising

- Extended lubricant life due to low volatility and outgassing

- Non-hazardous and non-toxic

- Indefinite shelf life if unopened and stored in a clean, dry location

- Minimal environmental footprint; no damage to the atmosphere or ozone layer

- Both oils and greases are suitable for automated spray application

- Resistance to acidic or caustic cleaners and disinfectants, steam, and moisture

Lubricate rubber seals to benefit from reduced maintenance and repair costs while improving their safety, efficiency and product quality.

Molykote 111, a versatile lubricant and sealant, excels in effectively lubricating rubber and plastic seals. It boasts robust resistance to a wide range of chemicals and exceptional water repellency. This lubricant is especially well-suited for outdoor equipment exposed to water and harsh environmental conditions, preventing o-rings from adhering to metal surfaces. Its durability extends to applications involving pressure connections, control valves, and vacuum systems.

Meanwhile, Krytox NRT 8906, a high-performance grease, thrives in high-temperature environments. It’s an excellent choice for lubricating rubber seals, valves, pumps, motors, and bearings. Its superior film-forming properties and non-reactive nature ensure optimal lubrication and protection.

Beyond rubber seals, explore how our high-performance lubricants can effectively mitigate thread failures, maintain hermetic integrity in autoclave doors, and optimize the performance of valves and bearings.