Dow Silicones is extending its portfolio of products to control the temperature of EV batteries and safeguard the durability of electrified vehicle powertrains

EV BATTERIES AND DURABILITY OF ELECTRIFIED VEHICLE POWERTRAINS

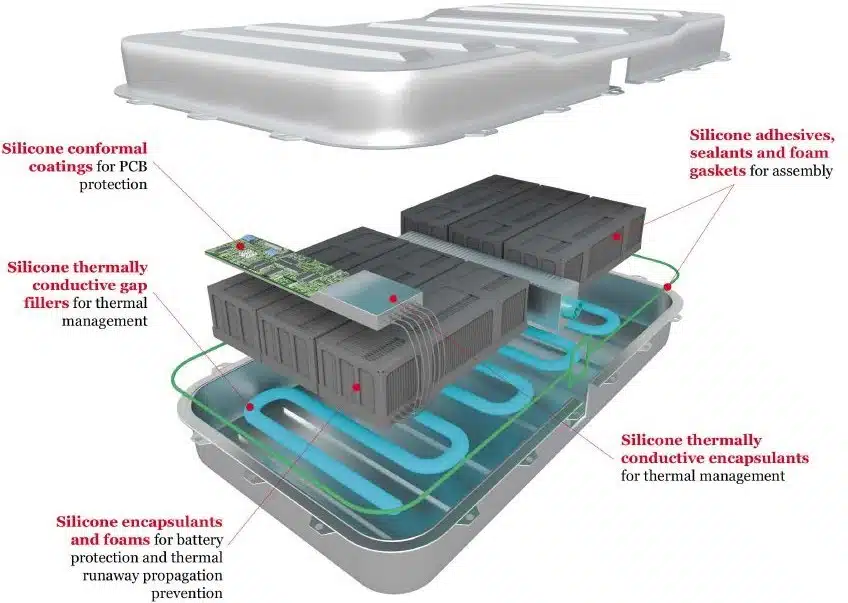

The heat management issues arising from more powerful, fast-charging battery packs and densely packed battery management systems (BMS) are among the EV design challenges being met by products from Dow Silicones.

Dow’s global network of research and application engineers is working alongside its tier supplier and OEM customers in the specialized fields of batteries, BMS, power control units, inverters, chargers and electric motors. Its products – such as thermally conductive adhesives, gap-fillers and encapsulants – are preventing runaways, dissipating heat and ensuring the durability of electrified vehicle powertrains.

The good news for customers is that new products are hitting the market this year, with more planned for the coming 3-5 years.

“We have an extremely deep technical pipeline,” confirms John McKeen, global director of technical service and development for mobility and transportation at Dow Consumer Solutions. “Earlier this year we launched a new silicone gap-filler called DOWSIL TC-5515LT that was specifically designed to dissipate heat in EV battery packs. It’s a UL V-0-rated material with a heat-transfer coefficient of 1.7 or 2W/m-K, depending on the test method that is chosen. It has a lower specific gravity than some of the competitive materials so that it achieves weight savings while delivering the appropriate thermal conductivity.

“As required by customers, the new product has good non-slumping behavior and low squeeze force for assembly or even rework if needed,” he continues. “We’ve designed it to be easy to apply. You have to insert a prismatic cell onto the cooling plate under low force so that you don’t damage the cell and such that the [gap-filler] material spreads out and forms a nice, uniform layer between the plate and the bottom of the cell. We’ve formulated the material to achieve that and also designed itto cure quickly at room temperature, to save energy and boost production efficiency.”

ACCELERATED TESTING

McKeen notes that even if high-volume materials like gap-fillers aren’t always fine-tuned for a specific customer, it’s still possible to refine them for the manufacturing application – how the customer would like to dispense it, for example. He also points to his team’s comprehensive test program, which is designed to demonstrate the long-term performance of the product in its vehicle application.

“We focus on demonstrating reliability,” he says. “We work with our mechanical engineering center and use our global analytical capabilities to perform accelerated ageing tests, including thermal cycling and at elevated temperatures. We’ve already started to see some success with the new material and have a couple of major wins in China with customers who will take the product globally.”

Further new, thermally conductive gap-fillers are on the way. McKeen highlights a number of products in development, ranging from 2W/m-K to more than 6W/m-K.

“We don’t only bring the formula to the table but deliver on the customer and market-specific requirements around adhesion, dispensability or flowability, and focus on validating long-term reliability,” he says.“We are also working on several encapsulating foams and different types of rubber sheets or composite products targeted cylindrical, prismatic and pouch cells, and modules built from them. The goal is to mitigate or limit thermal propagation. We’ve been sampling some new foam materials into the market and we’re starting to see good feedback. Application testing with partners has shown that if you have a runaway cell, the material limits the propagation to neighboring cells. We formulate them so that they can be easily dispensed and fi ll small gaps between the cells.”

“The electronics and automotive industries are merging more and more, with new players coming in” – John McKeen, global director of technical service and development for mobility and transportation, Dow Consumer Solutions

FLEXIBLE FUTURE

McKeen says that Dow is taking an agnostic view on which type(s) of battery cell and/or chemistry will prove dominant in the market in the future. “Our view is that the jury is still out on what the winning technology or technologies will be,” he explains. “We have engagements with customers on all different types of cells and continue to refi ne the products that we’re bringing to market. One of the strengths of Dow is having access to multiple chemistry sets. If the silicone doesn’t fit the application need, we can access strong partnerships with our polyurethanes (PU) or plastics organizations, or others.”

Launched in July 2020, Dow’s MobilityScience is a market platform that aims to bring together business units handling silicones, PU, plastics and more. The objective is to provide one face to the tier suppliers and OEM customers, enabling faster access to Dow’s different technologies and thereby improving the customer experience. Together, MobilityScience accounts for around US$2bn in automotive business annually.

Dow serves multiple industries beyond the automotive sector, including building and infrastructure, personal care and consumer electronics. McKeen sees the company’s ability to leverage materials technology from diff erent sectors as a competitive advantage.“

The electronics and automotive industries are merging more and more, with new players coming in,” he assesses. “We have a similar portfolio in the electronics market, and we can leverage technologies and innovations from one market to another. As an example, the TC-5515 gap-filler was developed specifically for EV batteries, but leverages decades of success with other thermally conductive materials – not just in the automotive market but in electronics as well. There are similar demands to remove more heat in both sectors.”

GROWTH AHEAD

Dow is optimistic about the prospects for growth in electrified sales, having been encouraged by the way the market has rebounded from the challenging first half of 2020. “We’re seeing an acceleration in electrification in the mix of vehicles sold,” says Jeroen Bello, Dow’s global marketing director for mobility and transportation. “The latest reports from IHS, Bloomberg and McKinsey have all adjusted the [forecast] numbers upwards and we see the same trend. Customers are being incentivized to buy EVs by Chinese government policies and the European Green Deal. With all the applications that we have in electrified vehicles, we expect double-digit growth in the coming five years.

- Dow Silicones has major engineering and laboratory capabilities in the USA, Europe, Shanghai and Japan to assist locally based OEMs, supported by further technical service facilities worldwide.

- Aimed at the proliferating volume of electronics in electric and/or autonomous vehicles, Dow’s new DOWSIL EC-6601, an electrically conductive adhesive, recently won the R&D 100 and silver at the Edison Awards. It’s designed to provide high elongation, good shielding and strong adhesion, durability and conductive performance.

- In the next 3-5 years, Dow Silicones will launch further new thermally conductive gap-fillers and adhesives for difficult-tobond substrates.

Source | Electric & Hybrid Vehicle Technology International Magazine (www.electrichybridvehicletechnology.com)