How Krytox™ Performance Lubricants Can Reduce Component Failures and Extend Vehicle Life

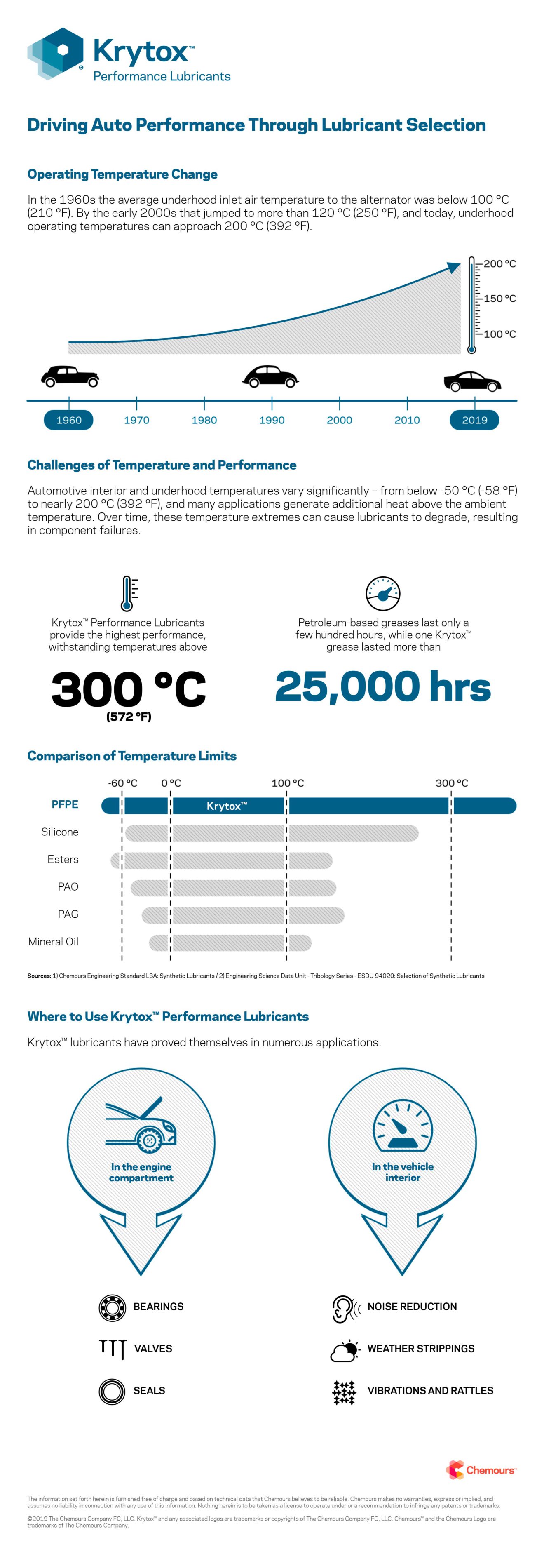

In the 1960s the average underhood inlet air temperature to the alternator was below 100 °C (210 °F). By the early 2000s that jumped to more than 120 °C (250 °F), and today, underhood operating temperatures can approach 200 °C (392 °F). Finding a lubricant that can withstand the rising temperatures and harsh conditions over an extended period is critical to optimal vehicle performance.

High performance lubricants, such as perfluoropolyethers (PFPEs), excel in these conditions, creating a ripple effect of value: reducing component failures, extending vehicle life, reducing warranty claims, improving quality and customer loyalty, and increasing profitability.

Understanding the Challenges of Temperature and Performance

Automotive interior and underhood temperatures vary significantly—from below -50 °C (-58 °F) to nearly 200 °C (392 °F), and many applications generate additional heat above the ambient temperature. Over time, these temperature extremes can cause lubricants to degrade, resulting in component failures.

For example, most standard petroleum-based greases begin to oxidize and degrade above 100 °C (212 °F). Synthetic lubricants (e.g., esters, polyalkylene glycols, and polyalphaolefins) can survive at higher temperatures, but the PFPE lubricants provide the highest performance, withstanding temperatures above 300 °C (572 °F).

Lubricant performance also varies significantly based on loads, speeds, and environmental conditions—including exposure to corrosive road deicers, fuel, and other materials.

During a standard bearing endurance test (ASTM D-3336) at 10,000 revolutions per minute, petroleum-based greases last only a few hundred hours, while one PFPE grease lasted more than 25,000 hours.

Given the unique performance capabilities of each lubricant, understanding the strengths and weaknesses of each lubricant class can help maximize performance.

Most standard petroleum-based greases begin to oxidize and degrade above 100 °C (212 °F). Synthetic lubricants (e.g., esters, polyalkylene glycols, and polyalphaolefins) can survive at higher temperatures, but the PFPE lubricants provide the highest performance, withstanding temperatures above 300 °C (572 °F).

The Automotive Lubricant Landscape

Here’s a capability overview of common automotive lubricant classifications

Perfluoropolyethers (PFPEs)

PFPEs are a class of synthetic lubricants used in demanding applications due to their combination of physical and chemical properties. PFPEs offer excellent thermal and chemical stability, low volatility, and unmatched lubricity at extreme temperatures. PFPEs are the ideal lubricant when high performance is needed in an extreme environment, and can also be the lubricant of choice for applications requiring other properties, such as chemical inertness and extreme pressure capability. Vehicle warranties can typically be extended due to the long-lasting performance of these lubricants.

Mineral

Mineral lubricants offer excellent hydrolytic stability and good seal material compatibility, lubricating ability, and toxicity. However, mineral lubricants provide poor fire resistance and only moderate thermal and oxidation stability.

Polyalphaolefins (PAOs)

PAO lubricants boast excellent hydrolytic stability and toxicity, along with above average oxidation stability, volatility, seal compatibility, and lubricating ability. Yet, the lubricant has limited capabilities across temperature extremes, with only moderate thermal stability and poor fire resistance.

Diester

Diester lubricants provide good thermal, oxidation, and hydrolytic stability, as well as above average lubricating ability, toxicity, and volatility. However, the lubricant has only moderate fire resistance and poor seal material compatibility.

Polyol Ester

Polyol ester lubricants have similar performance capabilities to diesters, but with improved hydrolytic stability, slightly stronger thermal stability, and overall lubricating ability.

Silicones

Silicone lubricants have good chemical inertness, thermal stability, and low volatility, making them a good lubricant choice for certain applications. However, their lubricating film-forming capability is low; and, consequently, silicone lubricants cannot support high loads. Silicones are also known to migrate easily, which can cause serious concerns in a vehicle assembly plant, particularly around paint lines.

Where to Use Krytox™ Performance Lubricants (PFPE)

The many automotive applications of Krytox™ Performance Lubricants (PFPEs) generally fall into two categories:

Under the Hood

Underhood temperatures are gradually rising as aerodynamics dictate tighter packaging and large engines are being replaced by smaller turbocharged and supercharged engines for improved fuel efficiency. With ambient temperatures under the hood exceeding 120 °C (248 °F), PFPEs have a growing list of automotive applications, including:

- Overrunning decouplers for alternator drive pulleys

- Front end accessory drive (FEAD) tensioners and idlers

- Throttle body bearings

- EGR valves

- Variable-geometry intake manifold valves

- Fuel system emission control valves

- Electric cooling system pumps and valves

- Ignition system boots

Vehicle Interior and Noise, Vibration, and Harshness

PFPEs are particularly effective at eliminating squeaks and associated noises on and inside vehicles without any concern over material compatibility. PFPEs significantly reduce friction and energy buildup between surfaces that can lead to noises when the parts rub against each other. Application categories include:

- Interior plastics

- Instrument panels

- Door trim

- Center and overhead consoles

- Leather seats and seat latches

- Electric switches

- Weatherstrips and seals