Brighter, more energy-efficient and longer-lasting lighting systems

The demand is everywhere. Innovative materials can help you meet that demand. Dow’s high-performance silicones – and their lighting, technical, optical and process expertise – can help make your ideas brighter.

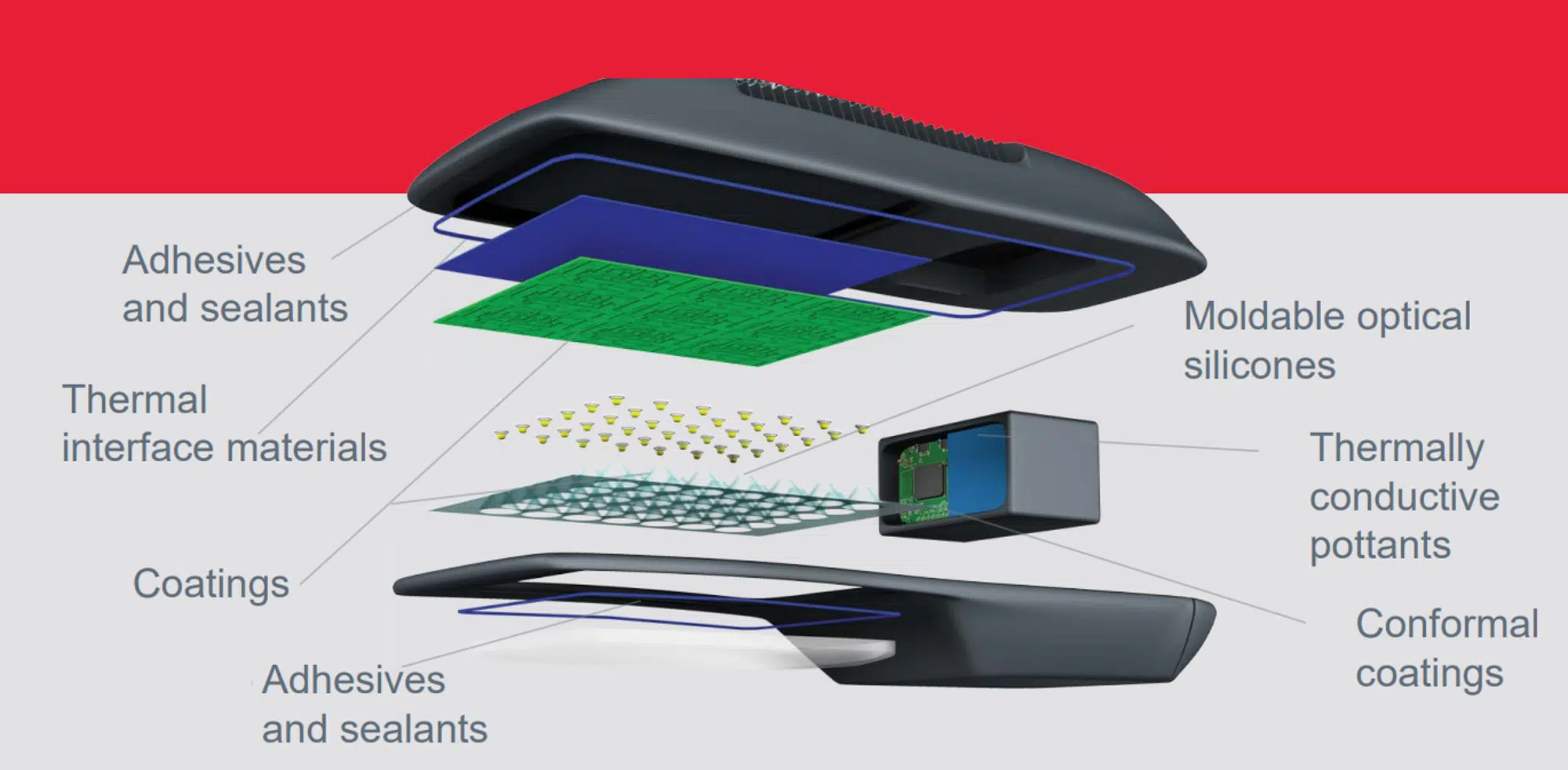

a) Solutions for LED Luminaires

Adhesives and sealants

By forming durable, low-stress elastomers, DOWSIL™ thermal adhesives and sealants increase your design flexibility, while providing reliable long-term performance. They offer excellent bonds and seals between a variety of common LED lamp and luminaire materials.

- DOWSIL™ 3-1944 RTV Coating

- DOWSIL™ 3140 RTV Coating

- DOWSIL™ 3165 Fast Tack RTV Adhesive Sealant

- DOWSIL™ 7091 Adhesive Sealant

- DOWSIL™ 832 Multi-Surface Adhesive Sealant

- DOWSIL™ EA-2900 Sealant

- DOWSIL™ EA 3500G Fast-Cure Silicone Adhesive

- DOWSIL™ EA-4900 White RTV Adhesive

- DOWSIL™ HM-2600 Silicone Assembly Sealant

- DOWSIL™ SE 9186 Sealant

- DOWSIL™ SE 9187 L Adhesive

- DOWSIL™ SE 9189 L RTV Adhesive

Thermal interface materials

Nothing shortens lifespan more than heat … and LED electronics generate a lot of it. By designing with DOWSIL™ thermal interface materials, you have more heat management options. Thermal Adhesives form thermally stable bonds to most LED PCB substrates and deliver excellent thermal conductivity. Their low volatility means no adverse impact on components or light output. Dispensable Thermal Pads allow you to quickly and precisely print thermally conductive silicone pads in controllable thicknesses on complex substrate shapes. They offer you enhanced thermal

performance and can accelerate production and, in many cases, reduce system costs.

- DOWSIL™ 1-4173 Thermally Conductive Adhesive

- DOWSIL™ 3-6752 Thermally Conductive Adhesive

- DOWSIL™ EA-9189 H RTV Adhesive

- DOWSIL™ SE 4485 Thermally Conductive Adhesive

- DOWSIL™ SE 4486 Thermally Conductive Adhesive

- DOWSIL™ TC-4025 Dispensable Thermal Pad

- DOWSIL™ TC-5026 Thermally Conductive Compound

- DOWSIL™ TC-5080 Thermally Conductive Grease

- DOWSIL™ TC-5629 Thermally Conductive Compound

Moldable optical silicones

You will find an unprecedented level of design freedom with moldable optical silicones from Dow. They allow you to explore more complex architectures – often while simplifying the manufacturing process.

They can also boost the long-term performance of your design. Not only do they offer excellent optical properties, they are more resistant to impact damage and degradation from UV, heat and environmental extremes than traditional optical materials – delivering high lumen density while remaining stable over time.

- SILASTIC™ MS-0002 Moldable Silicone

- SILASTIC™ MS-1002 Moldable Silicone

- SILASTIC™ MS-1003 Moldable Silicone

- SILASTIC™ MS-2002 Moldable Silicone White Reflector

- SILASTIC™ MS-4002 Moldable Silicone

- SILASTIC™ MS-4007 Moldable Silicone

Thermally conductive pottants

Environmental contamination and thermal damage are two of the biggest threats to the long-term reliability of your LED lamp or luminaire. DOWSIL™ and SYLGARD™ thermal pottants protect LED drivers from moisture and dust while dissipating heat and absorbing component noise.

- DOWSIL™ CN-8760 Thermally Conductive Encapsulant

- SYLGARD™ 160 Silicone Elastomer

- SYLGARD™ 164 Silicone Elastomer

- SYLGARD™ 170 Fast Cure Silicone Elastomer

- SYLGARD™ 170 Silicone Elastomer

- SYLGARD™ 567 Primerless Silicone Encapsulant

Conformal coatings/gels

Delicate PCB systems components need protection from heat, humidity, moisture and physical stress. DOWSIL™ conformal coatings provide that protection – and deliver excellent insulation against shock and short circuits. They provide excellent unprimed adhesion to many common LED materials.

- DOWSIL™ 1-2577 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

- DOWSIL™ 1-2620 Low VOC Conformal Coating

- DOWSIL™ 1-4105 Conformal Coating

- DOWSIL™ 3-1944 RTV Coating

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-4154 Dielectric Gel Kit

- DOWSIL™ 3-4207 Dielectric Tough Gel

- DOWSIL™ 3140 RTV Coating

- DOWSIL™ CC-2570 Conformal Coating

- DOWSIL™ CC-2571 Conformal Coating

- DOWSIL™ CC-3122 Conformal Coating

- DOWSIL™ EG-4131 Dielectric Gel

- SYLGARD™ 527 Silicone Dielectric Gel

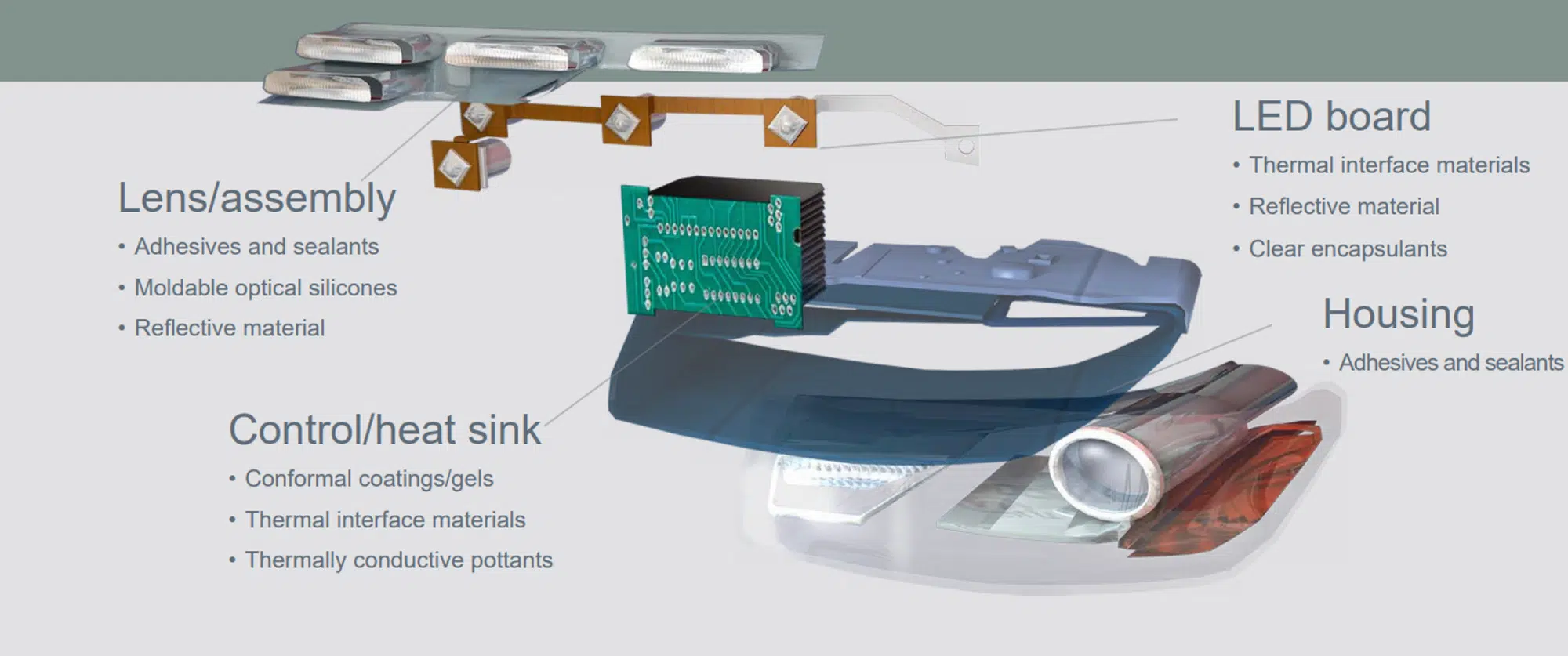

b) Solutions for LED Headlamp assemblies

Lens/assembly

This is the business end of your headlamp assembly. Silicone adhesives, optics and reflective coatings from Dow offer you new freedom of design and increased performance – thanks to the unique properties of silicones and our global network of experts.

1. Adhesives and sealants

By forming durable, low-stress elastomers, DOWSIL™ thermal adhesives and sealants increase your design flexibility, while providing reliable long-term performance. They offer excellent bonds and seals between a variety of common LED lamp and luminaire materials.

- DOWSIL™ 3-1944 RTV Coating

- DOWSIL™ 3140 RTV Coating

- DOWSIL™ 3165 Fast Tack RTV Adhesive Sealant

- DOWSIL™ 7091 Adhesive Sealant

- DOWSIL™ 832 Multi-Surface Adhesive Sealant

- DOWSIL™ EA-2900 Sealant

- DOWSIL™ EA 3500G Fast-Cure Silicone Adhesive

- DOWSIL™ EA-4900 White RTV Adhesive

- DOWSIL™ HM-2600 Silicone Assembly Sealant

- DOWSIL™ SE 9186 Sealant

- DOWSIL™ SE 9187 L Adhesive

- DOWSIL™ SE 9189 L RTV Adhesive

2. Moldable optical silicones

You will find an unprecedented level of design freedom with moldable optical silicones from Dow. They allow you to explore more complex architectures – often while simplifying the manufacturing process. They can also boost the long-term performance of your design. Not only do they offer excellent optical properties, they are more resistant to impact damage and degradation from UV, heat and environmental extremes than traditional optical materials – delivering high lumen density, while remaining stable over time.

- SILASTIC™ MS-0002 Moldable Silicone

- SILASTIC™ MS-1002 Moldable Silicone

- SILASTIC™ MS-1003 Moldable Silicone

- SILASTIC™ MS-2002 Moldable Silicone White Reflector

- SILASTIC™ MS-4002 Moldable Silicone

- SILASTIC™ MS-4007 Moldable Silicone

3. Reflective material

This award-winning moldable silicone is a white reflective material which enables creativity and flexibility in designing and manufacturing light reflectors. This is a high viscosity, high Shore A hardness, fast curing optical molding resin for producing fine details with good resistance to environmental aging. DOWSIL™ MS-2002 Moldable Silicone allows for excellent mold detailing or feature reproduction, and the ability to mold undercuts, etc. allows for more flexibility in your designs.

- SILASTIC™ MS-2002 Moldable Silicone White Reflector

Control/heat sink

Heat management is one of the most vital considerations in your LED headlamp design. Silicone thermal management materials from Dow offer you highly stable and versatile options to manage heat.

1. Conformal coatings/gels

Delicate PCB systems components need protection from heat, humidity, moisture and physical stress. DOWSIL™ conformal coatings provide that protection – and deliver excellent insulation against shock and short circuits. They provide excellent unprimed adhesion to many common LED materials.

- DOWSIL™ 1-2577 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

- DOWSIL™ 1-2620 Low VOC Conformal Coating

- DOWSIL™ 1-4105 Conformal Coating

- DOWSIL™ 3-1944 RTV Coating

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-4154 Dielectric Gel Kit

- DOWSIL™ 3-4207 Dielectric Tough Gel

- DOWSIL™ 3140 RTV Coating

- DOWSIL™ CC-2570 Conformal Coating

- DOWSIL™ CC-2571 Conformal Coating

- DOWSIL™ CC-3122 Conformal Coating

- DOWSIL™ EG-4131 Dielectric Gel

- SYLGARD™ 527 Silicone Dielectric Gel

2. Thermal interface materials

Nothing shortens lifespan more than heat … and LED electronics generate a lot of it. By designing with DOWSIL™ thermal interface materials, you have more heat management options. Thermal Adhesives form thermally stable bonds to most LED PCB substrates, and deliver excellent thermal conductivity. Their low volatility means no adverse impact on components or light output. Dispensable Thermal Pads allow you to quickly and precisely print thermally conductive silicone pads in controllable thicknesses on complex substrate shapes. They offer you enhanced thermal

performance and can accelerate production and, in many cases, reduce system costs.

- DOWSIL™ 1-4173 Thermally Conductive Adhesive

- DOWSIL™ 3-6752 Thermally Conductive Adhesive

- DOWSIL™ EA-9189 H RTV Adhesive

- DOWSIL™ SE 4485 Thermally Conductive Adhesive

- DOWSIL™ SE 4486 Thermally Conductive Adhesive

- DOWSIL™ TC-4025 Dispensable Thermal Pad

- DOWSIL™ TC-5026 Thermally Conductive Compound

- DOWSIL™ TC-5080 Thermally Conductive Grease

- DOWSIL™ TC-5629 Thermally Conductive Compound

3. Thermally conductive pottants

Environmental contamination and thermal damage are two of the biggest threats to the long-term reliability of your LED lamp or luminaire. DOWSIL™ and SYLGARD™ thermal pottants protect LED drivers from moisture and dust while dissipating heat and absorbing component noise.

- DOWSIL™ CN-8760 Thermally Conductive Encapsulant

- SYLGARD™ 160 Silicone Elastomer

- SYLGARD™ 164 Silicone Elastomer

- SYLGARD™ 170 Fast Cure Silicone Elastomer

- SYLGARD™ 170 Silicone Elastomer

- SYLGARD™ 567 Primerless Silicone Encapsulant

LED board

1. Thermal interface materials

Nothing shortens lifespan more than heat … and LED electronics generate a lot of it. By designing with DOWSIL™ thermal interface materials, you have more heat management options. Thermal Adhesives form thermally stable bonds to most LED PCB substrates, and deliver excellent thermal conductivity. Their low volatility means no adverse impact on components or light output. Dispensable Thermal Pads allow you to quickly and precisely print thermally conductive silicone pads in controllable thicknesses on complex substrate shapes. They offer you enhanced thermal performance and can accelerate production and, in many cases, reduce system costs.

- DOWSIL™ 1-4173 Thermally Conductive Adhesive

- DOWSIL™ 3-6752 Thermally Conductive Adhesive

- DOWSIL™ EA-9189 H RTV Adhesive

- DOWSIL™ SE 4485 Thermally Conductive Adhesive

- DOWSIL™ SE 4486 Thermally Conductive Adhesive

- DOWSIL™ TC-4025 Dispensable Thermal Pad

- DOWSIL™ TC-5026 Thermally Conductive Compound

- DOWSIL™ TC-5080 Thermally Conductive Grease

- DOWSIL™ TC-5629 Thermally Conductive Compound

2. Reflective material

This award-winning moldable silicone is a white reflective material which enables creativity and flexibility in designing and manufacturing light reflectors. This is a high viscosity, high Shore A hardness, fast curing optical molding resin for producing fine details with good resistance to environmental aging. DOWSIL™ MS-2002 Moldable Silicone allows for excellent mold detailing or feature reproduction, and the ability to mold undercuts, etc. allows for more flexibility in your designs.

- SILASTIC™ MS-2002 Moldable Silicone White Reflector

3. Clear encapsulants

One way to realize greater cost efficiency, and lower your total cost of ownership is through materials that can perform multiple functions. DOWSIL™ secondary optical encapsulants offer you that

opportunity. These materials provide superior protection from moisture, thermal stress, shock and impact, and offer excellent optical performance. You can count on minimal yellowing and degradation, while maintaining consistent light quality over the product lifespan.

Secondary optical encapsulants:

- DOWSIL™ EI-1184 Optical Encapsulant

- DOWSIL™ EI-2888 Primerless Silicone Encapsulant

Housing

Your assembly depends on the integrity of its housing. DOWSIL™ silicone adhesives and sealants help you maintain a moisture-, dust- and dirt-proof environment with long-lasting adhesion under the most demanding conditions

1. Adhesive and sealants

By forming durable, low-stress elastomers, DOWSIL™ thermal silicone adhesives and sealants increase your design flexibility, while providing reliable long-term performance. They offer excellent bonds and seals between a variety of common LED lamp and luminaire materials.

- DOWSIL™ 3-1944 RTV Coating

- DOWSIL™ 3140 RTV Coating

- DOWSIL™ 3165 Fast Tack RTV Adhesive Sealant

- DOWSIL™ 7091 Adhesive Sealant

- DOWSIL™ 832 Multi-Surface Adhesive Sealant

- DOWSIL™ EA-2900 Sealant

- DOWSIL™ EA 3500G Fast-Cure Silicone Adhesive

- DOWSIL™ EA-4900 White RTV Adhesive

- DOWSIL™ HM-2600 Silicone Assembly Sealant

- DOWSIL™ SE 9186 Sealant

- DOWSIL™ SE 9187 L Adhesive

- DOWSIL™ SE 9189 L RTV Adhesive

c) Solutions for Optical coupling

DOWSIL™ optical gels have been used extensively to seal and protect, by coating, encapsulating, or potting various optoelectronics due to their stress relieving capabilities and high refractive index, as well as the stability of these properties over time. Cured gels retain much of the stress and self-healing qualities of a liquid, while providing the dimensional stability of an elastomer – which is increasingly needed for delicate components.

Optical coupling gels:

- DOWSIL™ EG-1200 Gel

- DOWSIL™ EG-4131 Dielectric Gel

- DOWSIL™ VE-6001 UV Optical Bonding

d) Solutions for Clear encapsulants

One way to realize greater cost efficiency, and lower your total cost of ownership is through materials that can perform multiple functions. DOWSIL™ secondary optical encapsulants offer you that opportunity. These materials provide superior protection from moisture, thermal stress, shock and impact, and offer excellent optical performance. You can count on minimal yellowing and degradation, while maintaining consistent light quality over the product lifespan.

Secondary optical encapsulants:

- DOWSIL™ EI-1184 Optical Encapsulant

- DOWSIL™ EI-2888 Primerless Silicone Encapsulant

LED innovation ecosystem

As an LED lighting customer, you will gain the support of the Dow LED Innovation Ecosystem.

This broad and growing global network extends from Europe to Asia to the Americas and spans the entire LED value chain. It includes dozens of optical and LED component designers and manufacturers and offers the expertise you need to develop a true total solutions package with such services as:

- Material development

- Optical design

- Prototyping

- Analytical testing

- Application development

- Process development

You will also gain the support of our extensive global network of equipment manufacturers, distributors and specialty repackagers. Together, this array of resources and relationships offers you one of the most comprehensive sources for advanced materials solutions.

Source: Dow Product Selection Guide