High Performance Lubricants That Work in Demanding Automotive Bearing Applications

Reliable high-performance fluoropolymer lubricants from Chemours can stand up to even extreme conditions.

Krytox™ oils and greases have proven scientific and technical properties to help solve the most critical issues in the automotive industry.

Superior product performance, lower overall maintenance systems cost, and a lower environmental footprint help to meet rising consumer

expectations. For automotive manufacturers, this provides the opportunity to offer extended warranties and enjoy improved productivity through reduced component failure.

Krytox™ oils and greases are based on perfluoropolyether (PFPE) oils. These synthetic fluorinated lubricants are used in extreme conditions, such as continuous high temperatures up to 288 C

(550 F), and higher temperatures for shorter periods, depending on product grade limits.

Krytox™ oils and greases are exceptionally safe, reliable, and offer environmental benefits as well as longer lubricant life.

These oils and greases will not burn or support combustion, even in 100% liquid or gaseous oxygen, nor will they degrade or break down in the presence of aggressive chemicals.

In automotive applications, Krytox™ oils and greases deliver low temperature starting performance, while maintaining efficacy at higher temperatures. These oils and greases can increase service

life of critical components, allowing them to run more quietly and last longer, for superior, reliable performance

Krytox™ Lubricants for Automotive Bearing Applications

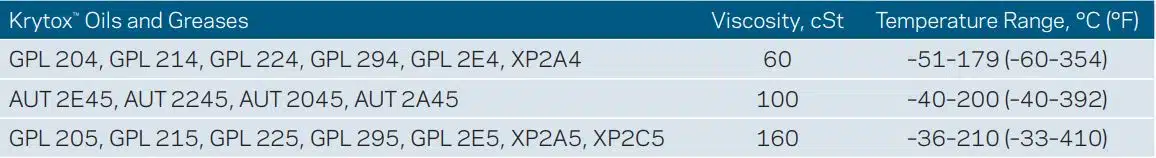

Several grades of Krytox™ oil and grease are suitable for automotive use, depending on the application type and temperature range encountered. The table above lists the most common grades currently being used.

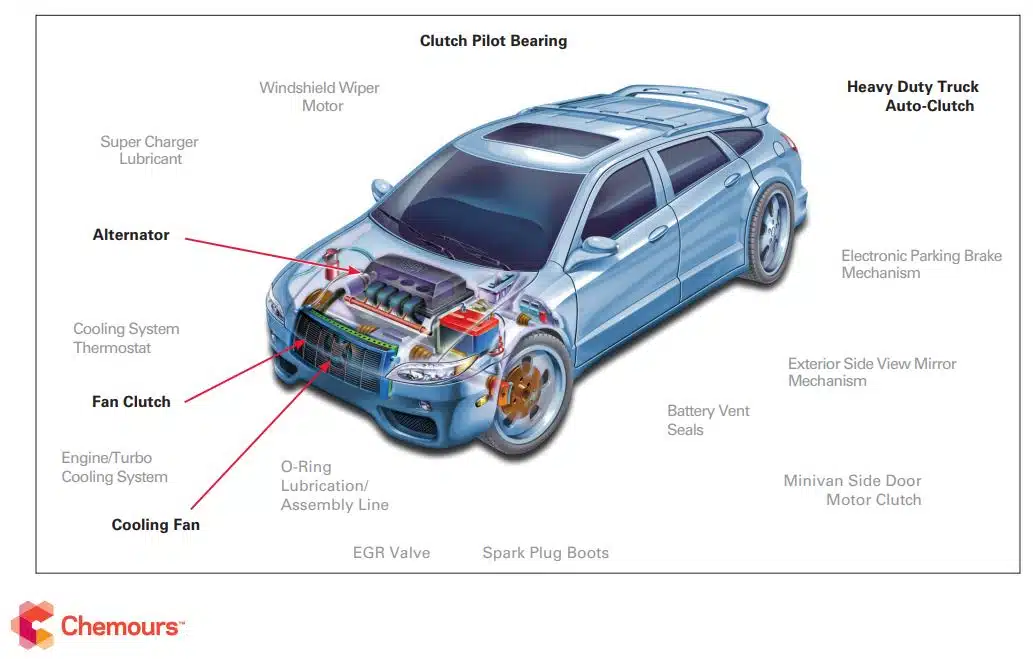

Proven Krytox™ Automotive Bearing Applications

Fan Clutch

A thermostatically controlled fan clutch typically drives the cooling fan. The bearings that support the drive shaft for this clutch regularly experience high temperatures.

If these bearings wear and begin to fail, the cooling fan runs less efficiently. When this occurs, the engine can overheat, and any resistance in fan clutch rotation can drain valuable power from the engine’s drive shaft, further reducing overall performance.

Krytox™ lubricants have low volatility and high viscosity, providing long life and excellent lubrication to the fan clutch bearing under these high temperature conditions.

Alternator

The alternator is usually belt-driven by the engine and supplies electricity to basic automobile functions (headlights, radio, etc.) while recharging the car battery.

As the electricity is being generated, the alternators and, hence, the bearings get very hot. Standard lubricants volatilize in the extreme high temperature environment of the alternator, leading to alternator bearing failure.

As the bearings wear and begin to fail, they can increase the alternator’s resistance to rotation. This reduces the alternator’s performance and robs performance from the rest of the automobile.

Perhaps more critically, if the alternator bearings fail, the alternator will fail and the vehicle will stop running. The higher output alternators used in today’s vehicles generate a tremendous amount of heat, demanding the advanced and reliable, heat-stability and performance of Krytox™ greases.

Clutch Pilot Bearings

The pilot bearings support the clutch-end of the transmission shaft. If the lubricant in the pilot bearing fails, the transmission itself will fail.

Pilot bearings lubricated with Krytox™ high performance lubricants will last longer and perform better than those lubricated with other synthetic lubricants, due to the high-load capability and chemical inertness of Krytox™ products.

Cooling Fan

To maximize performance, an automobile’s engine must run at its optimal temperature (typically around 93 C [200 F]), which is controlled by the cooling system.

One component of the system is the cooling fan, which blows air through the radiator, removing excess heat.

Failure in the cooling fan’s bearings leads to failure of the fan, which will eventually result in overheating of the engine.

The sintered bearings used in cooling fans often fail in two ways: either the lubricant volatilizes, or it degrades through oxidation.

The use of Krytox™ prevents both of these modes of failure, due to its low volatility and unsurpassed resistance to oxidation.

Heavy Duty Truck Automatic Clutch

In many heavy duty trucks, where the use of adas (advanced driver-assistance systems) may be present to help ensure driver safety, it is known that the engines have a much lower rpm upper limit. In order to prevent the engine from being destroyed, an automatic clutch is used.

When the set maximum rpm limit is reached, the automatic clutch disengages and notifies the driver to shift gears.

This both prevents engine damage and increases ease of operation. The bearings present in the clutch are critical to its operation and must receive adequate lubrication in order to work properly.

Lubricating with Krytox™ mid-range viscosity and low volatility lubricants reduces the chance that the bearings will fail with the frequent gear-shifting and high loads experienced throughout the extended driving life of these trucks.

Other Applications

Krytox™ lubricants are commonly used to extend service life of chassis components and power train components including:

- Anti-lock brakes

- Alternators

- Clutch release bearings

- Belt pulleys

- CV/universal joints

- Wheel bearings

- Cooling fan motors

Design Advantages with Krytox™ Lubricants for Automotive Bearing Applications

- Increase temperature rating

- Maintenance-free operation

- Extended service life

- Resistance to extreme environments

- Nonflammability

- Low noise operation

Recommended Grease Fill

Due to superior performance and higher specific gravity, grease fill with Krytox™ lubricants can be reduced without reducing service life. Medium-speed bearings with DN values (inner ID in mm x rpm) of 50,000–200,000 can be filled 35%. For higher speed applications, grease fill can be reduced to 25%.

Film Strength Durability

Krytox™ lubricants have been proven to exhibit superior film strength durability under extreme loads compared to synthetic hydrocarbons, advanced esters, polyalkyl aromatics, etc. Supporting test results have been published by the NASA Lewis Research Center in ASLE transactions.

Superior Bearing Life

Krytox™ lubricants have been tested per ASTM and DIN bearing tests at speeds ranging from 10,000–20,000 rpm to demonstrate extended service life.

Download the new eBook to explore how automotive engineers are relying on Krytox™ Performance Lubricants to boost performance.