High-value, high-performance long-term lubrication

Often described as “lubricating paints,” MOLYKOTE® AFCs contain solid lubricants – rather than coloring pigment – dispersed through carefully selected resin blends and solvents. The choice of raw materials and the concentration of each ingredient are important to the application-based customization of each coating.

MOLYKOTE® AFCs form a dry film and optimize friction of metal, plastic and elastomer parts – even under intense loads and harsh operating and environmental conditions.

The coatings are easy to apply by spraying, brushing, dip-spinning, roll-coating or screen printing. After curing, the bonded, dry lubricating film provides durable wear protection with a certain level of corrosion protection and resists dust and contamination.

This makes MOLYKOTE® Anti-Friction Coatings ideal for use in dirty, dusty and humid environments and on inaccessible parts that require long-term lubrication.

Economical to apply, long-lasting and valued in uses where other lubricants fail, MOLYKOTE® AFCs provide:

- Dry, clean lubrication unaffected by dust, dirt and moisture

- Lifetime lubrication without aging, evaporation or oxidation

- Rust prevention without surface treatments (e.g., galvanizing)

- Nonflammable, nonstaining protection on metals, plastics and elastomers

- Controlled film thickness for exact load-bearing capabilities

- Fully effective lubrication, even after prolonged shutdown

MOLYKOTE® Anti-Friction Coatings help customers improve safety, reliability and performance by controlling friction and wear, preventing component failures, extending lubrication intervals, and reducing production and operating costs.

Delivering results in tough conditions

Operating principles and conditions

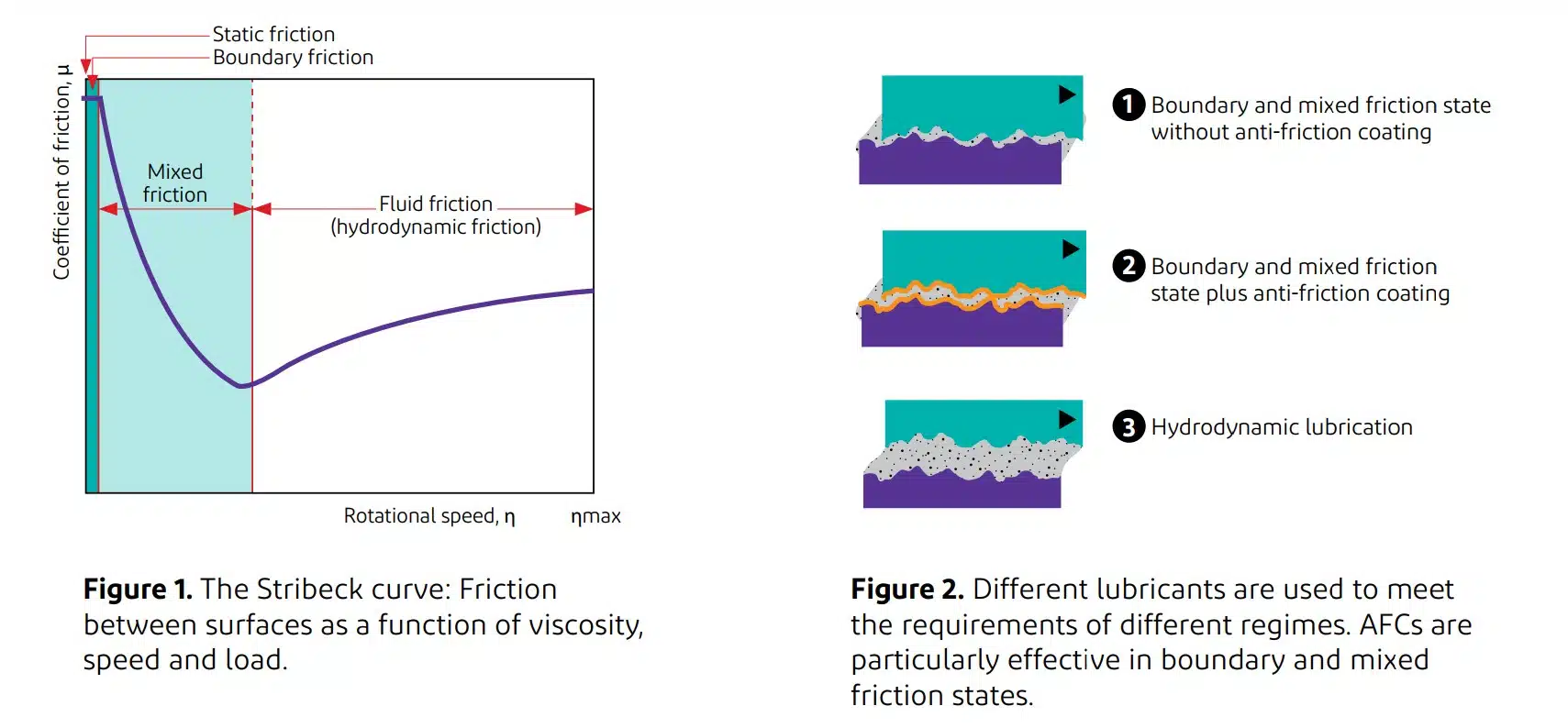

MOLYKOTE® Anti-Friction Coatings are particularly effective in boundary friction and mixed friction states, as illustrated in the Stribeck curve (Figure 1). In these states, direct metal-to-metal contact and wear take place because fluid hydrodynamic lubrication cannot be realized.

In MOLYKOTE® AFCs, the solid lubricants are kept on the substrate surface by the bonding force of the resin package so the surfaces are always separated by an effective dry film – whether under very low speeds, oscillating movements or high loads. MOLYKOTE® Anti-Friction Coatings also can support hydrodynamic lubrication as an agent to improve running-in. In addition, AFCs provide lubricity in case of hydrodynamic film breakdown.

Typical running-in effect and friction value

Anti-friction coatings generally are applied at 10-20 µm dry film thickness. Under load, the structure of the film is compacted, producing an extremely smooth surface covering the asperities of the carrier material (Figure 3). Coefficient of friction values of MoS2-based anti-friction coatings are compared to PTFE-based coatings in Figure 4. The coefficient of friction value of Mos2-based coatings drops after a short running-in phase.

Innovating through collaborative application engineering

MOLYKOTE® Anti-Friction Coatings offer finetuned solutions enabled by a customer-oriented development process – made possible by our network of global collaboration and technical development centers equipped with the latest tribological and analytical technology. When

customers work together with us, they have the full benefit of our:

- Tribology testing capabilities, from standard data sheet test methods to custom-designed test rigs to match specific customer applications

- Equipment to replicate part movement across a wide range of loads, environmental conditions, temperatures and speeds (LETS) to assist with all stages of development – from prototype to production and maintenance

- In-house coating research and development

- Deep knowledge in resin and solid lubricant technology

- Regional experts who translate customer application challenges into measurable lubricant solutions

In addition, we provide support for coating-line designs, process improvements and coating-shop recommendations. Combining DuPont™ resins with MOLYKOTE® lubricant expertise and advanced formulations will help us to develop better solutions for emerging trends and challenges.

Solutions for a wide range of applications

As fail-safe lubricants, MOLYKOTE® Anti-Friction Coatings are valued by the world’s leading engineers and manufacturers and are trusted for uses where maximum wear endurance is needed in a wide variety of applications – from increasingly electrified, autonomous and energy-efficient vehicles to industrial challenges where functionality, connectivity, safety and sustainability are critical.

Together, we can create lubrication solutions for your specific automotive and industrial applications. The next few pages highlight common application examples of MOLYKOTE® Anti-Friction Coatings.

Piston skirt coating

MOLYKOTE® D-10-GBL Anti-Friction Coating

MOLYKOTE® D-6024 Anti-Friction Coating

MOLYKOTE® PA 744 Anti-Friction Coating

For enhanced durability and emergency lubrication on pistons and piston rings; reduces noise and scuffing while increasing efficiency and fuel economy; screen-printable

Starter motor anchors

MOLYKOTE® D-6600 Anti-Friction Coating

Low friction for lifetime durability of metal/metal pairings; suitable for startstop system

Exhaust manifold gaskets

MOLYKOTE® D-6900 Anti-Friction Coating

MOLYKOTE® D-7620 Anti-Friction Coating

Improves sealing properties and avoids microseizing at high temperatures to meet Euro 6 norm; enables easier disassembly; designed for coil and roller coating

Lock mechanisms, lock-catching plates and locking levers, safety hooks

MOLYKOTE® 3400A LF Anti-Friction Coating

MOLYKOTE® D-708 Anti-Friction Coating

Long-term lubrication and corrosion protection; not affected by dust

Door panels, armrests, consoles, interior trim

MOLYKOTE® D-96 Anti-Friction Coating

MOLYKOTE® D-9630 Anti-Friction Coating

Lifetime anti-noise performance in cases where unfavorable material pairings are combined; when used as a replacement for nonwoven tape, it eliminates squeaks and rattles and represents an economical solution

Seat belt components

MOLYKOTE® D-6600 Anti-Friction Coating

MOLYKOTE® D-708 Anti-Friction Coating

Low-friction dry lubrication for lifetime durability of metal/metal pairings; nonstaining

Caliper springs and brake clips

MOLYKOTE® D-708 Anti-Friction Coating

MOLYKOTE® D-709 Anti-Friction Coating

Dry lubrication of steel springs in caliper brake pad sliding guides; works alongside a dry lubricant as an insulating anti-corrosion coating

Air conditioner swash plates

MOLYKOTE® D-6818 Anti-Friction Coating

MOLYKOTE® D-7409 Anti-Friction Coating

Excellent lubrication performance; high wear resistance; efficient processability; excellent chemical resistance

Air conditioner pistons

MOLYKOTE® D-6927 Anti-Friction Coating

Excellent lubrication performance; excellent chemical resistance to refrigerant and compressor oil; high wear resistance at mild conditions; efficient processability

Gears

MOLYKOTE® D-7409 Anti-Friction Coating

MOLYKOTE® 7400 Anti-Friction Coating

MOLYKOTE® D-321 R Anti-Friction Coating

High load-carrying capacity for running-in protection of heavily loaded gear sets

Threaded connections

MOLYKOTE® D-708 Anti-Friction Coating

MOLYKOTE® D-3484 Anti-Friction Coating

Defined, constant friction levels and corrosion protection for bolts, studs and nuts

Chains

MOLYKOTE® D-7409 Anti-Friction Coating

MOLYKOTE® D-3484 Anti-Friction Coating

MOLYKOTE® D-321 R Anti-Friction Coating

Long-life friction reduction for pins (MOLYKOTE® D-7409 Anti-Friction Coating, MOLYKOTE® D-3484 Anti-Friction Coating); reliable lubrication for complete chains (MOLYKOTE® D-321 R Anti-Friction Coating)

Springs

MOLYKOTE® D-321 R Anti-Friction Coating

MOLYKOTE® D-3484 Anti-Friction Coating

MOLYKOTE® D-7409 Anti-Friction Coating

Friction reduction to eliminate stick-slip and increase efficiency

Valves

MOLYKOTE® D-7409 Anti-Friction Coating

Operating efficiency; eliminates stick-slip; high chemical and fluid resistance

General assembly

MOLYKOTE® D-321 R Anti-Friction Coating

MOLYKOTE® 3402-C LF Anti-Friction Coating

Powerful dry-film lubricants for easy assembly of sliding parts; MOLYKOTE® 3402-C LF Anti-Friction Coating additionally offers good corrosion protection; MOLYKOTE® D-321 R AntiFriction Coating also is available in spray cans

Rubber and plastic components, such as O-rings and seals

MOLYKOTE® D-9100 Anti-Friction Coating

Translucent dry-film coating for rubber and plastic components; reduces and controls friction, wear and noise; flexible coating withstands part elongation; excellent adhesion; long service life; high productivity and processing speed with UV curing

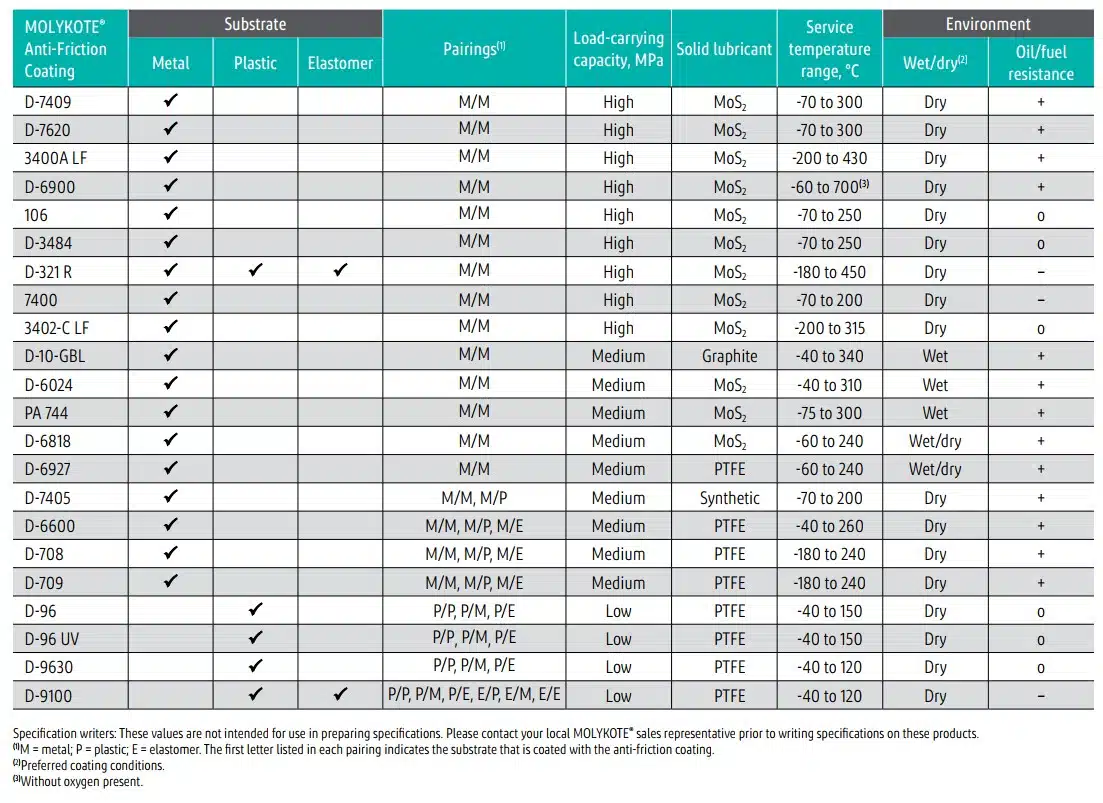

Product Selection

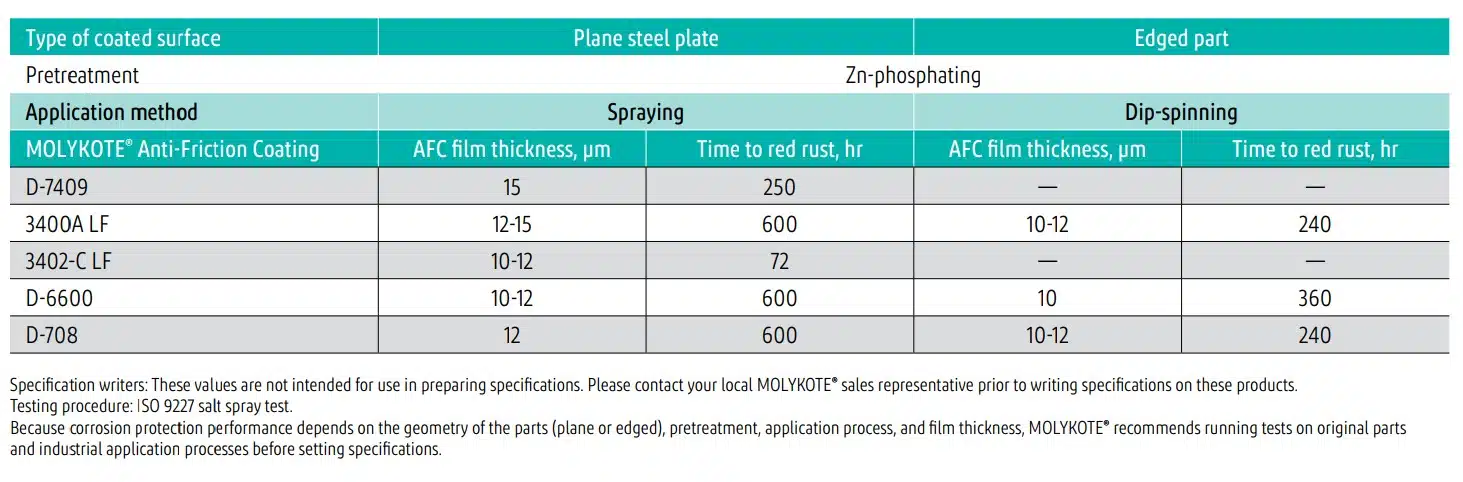

Selected coatings for corrosion protection

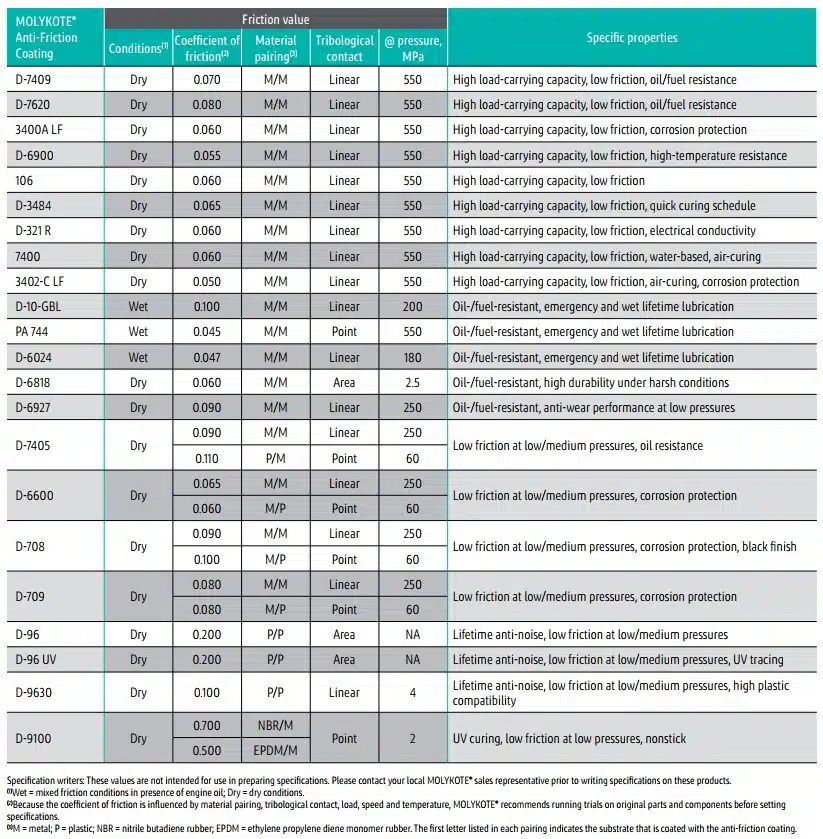

Friction values and specific properties

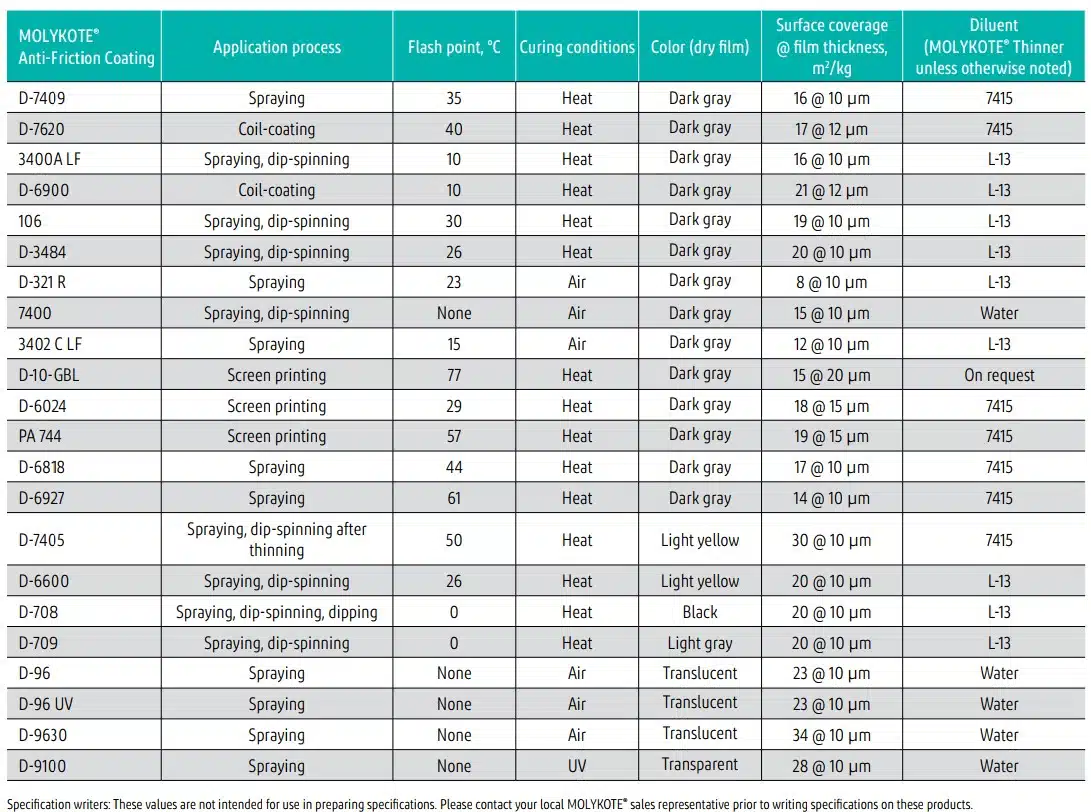

Application process

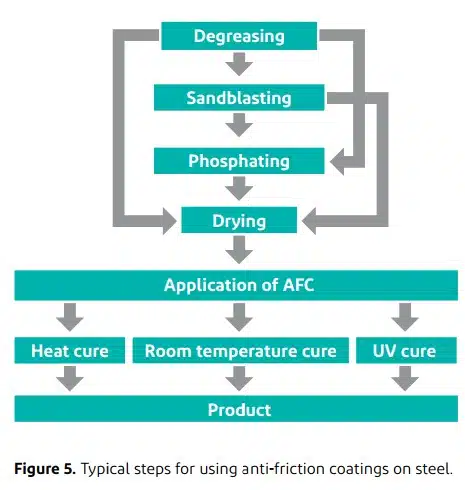

The coating process

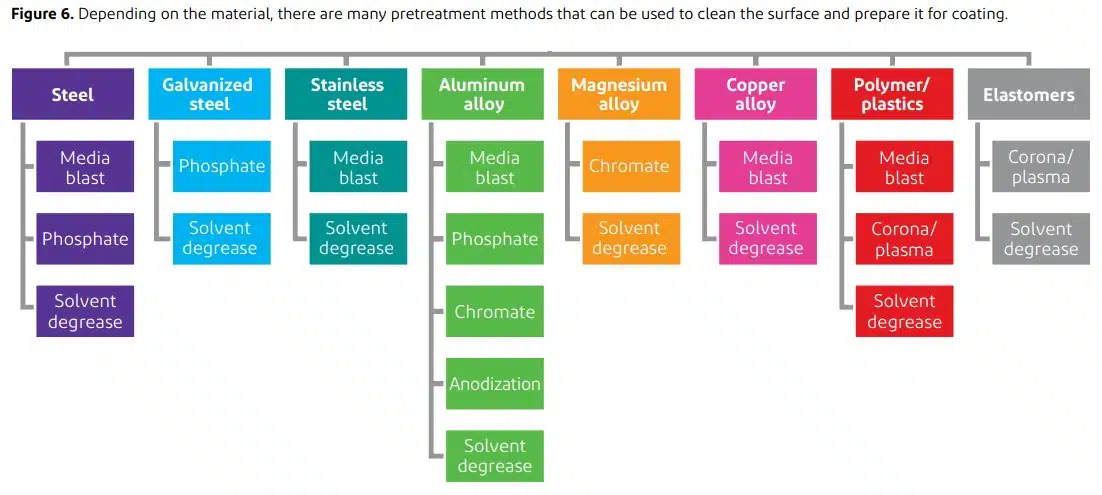

To ensure the effectiveness and full service life of MOLYKOTE® Anti-Friction Coatings, a proper coating process must be followed (Figure 5). Surface pretreatment plays a key role in coating service life and performance. Depending on the material, this can include processes such as solvent sonication, degreasing, media blasting, detergent washing, phosphating, anodizing, acid washing, e-coating, corona/plasma treatment and others (Figure 6).

Once the pretreated parts are dry and clean, different methods – varying by part geometry, weight, quantity and coating liquid viscosity – can be used to apply the anti-friction coating, including dip spinning, tumble spraying, HVLP spraying, screen printing, brushing, rolling and coil-coating.

Once coating is applied to the substrate, a curing process is required. Time to cure (from 2 to 90 minutes) and temperature needed (from ambient temperature up to 250°C) can vary, depending on the cure mechanism (heat, air or UV).

Pretreatment methods

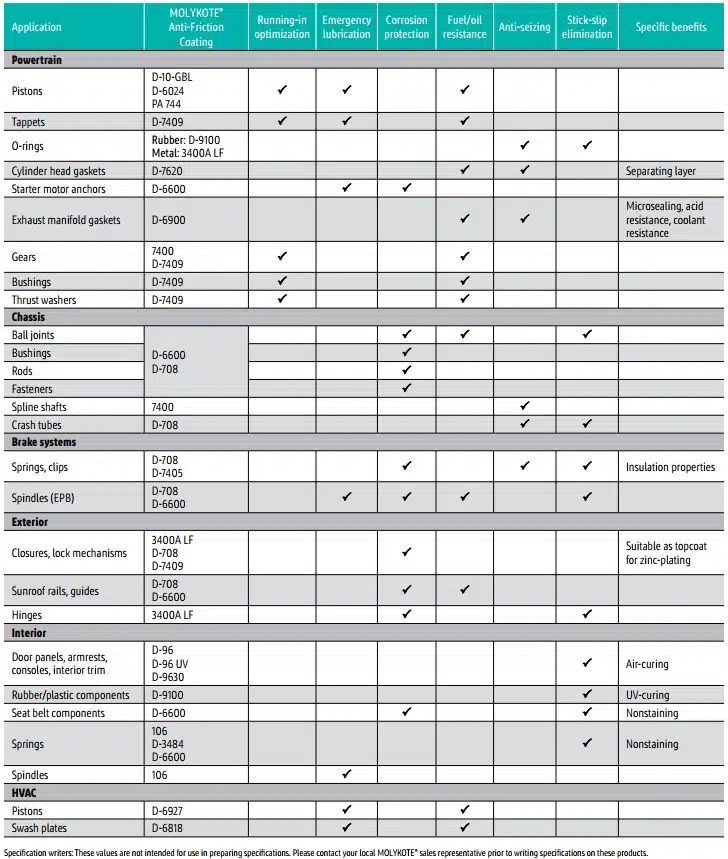

AFCs for automotive application needs

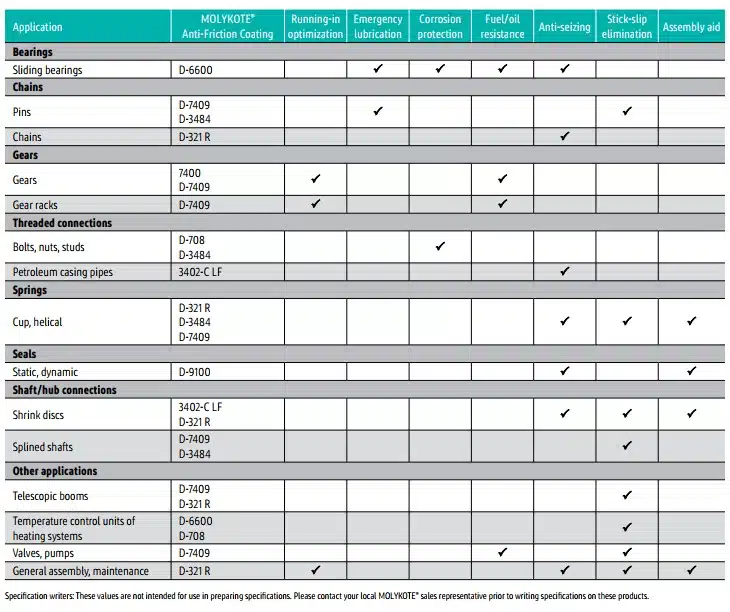

AFCs for industrial application needs

Source: Molykote ACF brochure