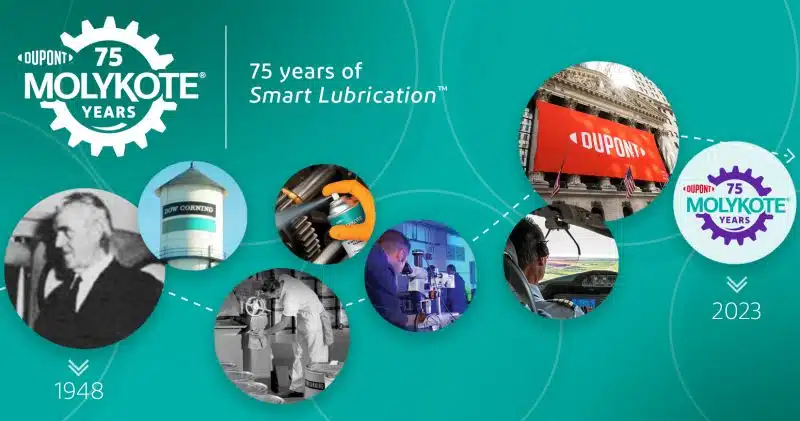

For decades, MOLYKOTE® has been a trusted partner, helping engineers and manufacturers meet some of the world’s toughest technical design and lubrication challenges. In 2023, we’re celebrating 75 years of application-matched Smart Lubrication™ solutions. We’ve come so far from our beginnings, when Alfred Sonntag introduced the world’s first molybdenum disulfide (MoS2) lubricants! Today, we offer a variety of lubricant technologies composed of ingredients that help tailor our specialty lubricants to your specific needs. Help us celebrate this milestone and learn more about MOLYKOTE® and our long history of keeping our customers moving: http://spr.ly/60403S5hg

Legendary performance for today and tomorrow

In 1948, American scientist Alfred Sonntag introduced the world’s first molybdenum disulfide (MoS2) lubricants – MOLYKOTE® brand – and began a rich history of customer-driven performance and materials innovation.

We continually invest in technology and product innovation to support customers’ changing needs. Working side by side with our customers, the MOLYKOTE® Specialty Lubricants brand is forging the future of lubrication with:

- A broad range of trusted, technology-driven specialty lubricant chemistries – our Smart Lubrication™ solutions

- Application expertise and technical support from internationally recognized lubrication experts

- Anti-friction coating, compound, dispersion, grease, paste, and oil solutions to meet megatrend needs and provide sustainable and efficient solutions

- Innovative combination of tribology and material science for wet and dry lubrication

Innovating through collaborative application engineering

MOLYKOTE® Specialty Lubricants offer fine-tuned solutions enabled by a customer-oriented development process – made possible by our network of global collaboration and technical development centers equipped with the latest tribological and analytical technology.

When customers collaborate with us, they have the full benefit of our:

- Tribology testing capabilities, from standard data sheet test methods to custom-designed test rigs to match specific customer applications

- Equipment to replicate part movement across a wide range of loads, environmental conditions, temperatures and speeds (LETS) to assist with all stages of development – from prototype to production and maintenance

- In-house coating research and development

- Deep knowledge in resin and solid lubricant technology

- Regional experts who translate customer application challenges into measurable lubricant solutions

In addition, we provide support for coating-line designs, process improvements and coating-shop recommendations. Now with DuPont™ polymers, MOLYKOTE® is expanding its collective understanding of polymer-grease compatibility under diverse conditions, which will allow customers to select products faster and move through evaluation more smoothly.