The shift to hydrogen as a key energy carrier in Europe is no longer a distant ambition—it is a present reality. Countries across the region are investing heavily in hydrogen refueling stations, fuel cell electric vehicles (FCEVs), and hydrogen-powered industrial equipment. At the core of this revolution lies one crucial requirement: hydrogen purity. That’s why DGE is proud to announce that MOLYKOTE® HP-300 Grease has officially achieved certification under ISO 14687:2019 Grade D, the international benchmark for hydrogen fuel quality. This certification makes HP-300 one of the few specialty lubricants verified for use in hydrogen applications where even the slightest contamination can cause serious risks.

Understanding Hydrogen Purity and Its Critical Role

Hydrogen systems are unique. They operate under extreme conditions—pressures up to 70 MPa, temperatures ranging from sub-zero to +250°C, and exposure to highly sensitive components like fuel cells and composite storage tanks.

Even microscopic impurities such as hydrocarbons, particulates, or reactive gases can:

- Shorten the life of proton exchange membrane (PEM) fuel cells

- Cause catalyst poisoning, reducing system efficiency and increasing costs

- Lead to premature equipment failure in hydrogen refueling stations and transport pipelines

Why Lubricants Pose a Hidden Contamination Risk

Lubricants are essential for protecting mechanical systems from friction and wear. However, many traditional lubricants outgas, degrade chemically, or leach compounds into the surrounding environment. In hydrogen systems, these effects can lead to hydrogen contamination—a costly and potentially dangerous issue.

Expert Insight – Dr. Thomas Stöhr, Hydrogen Systems Specialist

“In hydrogen refueling and fuel cell systems, purity isn’t just important—it’s mandatory. ISO 14687 exists to safeguard both the equipment and the energy efficiency of hydrogen as a fuel. Lubricants, despite being a small part of the system, can easily introduce impurities if not carefully engineered. That’s why the ISO certification of MOLYKOTE® HP-300 Grease is a major win for hydrogen operators.”

Why MOLYKOTE® HP-300 Grease Meets the Challenge

Engineered for Critical Environments

MOLYKOTE® HP-300 is based on perfluoropolyether (PFPE) base oil combined with a PTFE thickener, creating a formulation purpose-built for:

- Zero contamination performance: HP-300 has a very low vapor pressure, limiting outgassing under high pressure and vacuum conditions.

- Thermal stability: Reliable operation from -45°C to +250°C.

- Excellent chemical resistance: Fully compatible with hydrogen gas, solvents, and aggressive media.

- Material versatility: Safe to use on metals, plastics, and elastomers common in hydrogen components, including seals, valves, and fittings.

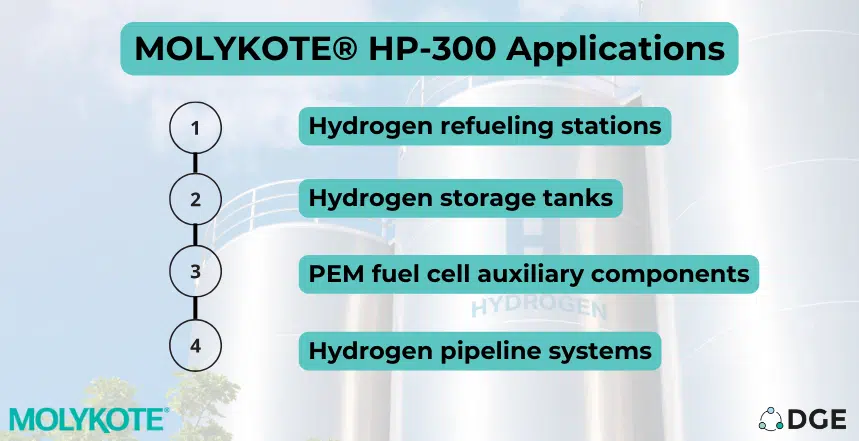

Applications where HP-300 Delivers

- Hydrogen refueling stations (valves, compressors, fittings)

- Hydrogen storage tanks (O-rings, gaskets, rotating equipment)

- PEM fuel cell auxiliary components (actuators, control mechanisms)

- Hydrogen pipeline systems (sealing and bearing points)

Proven Results Through Independent Certification

In 2024, MOLYKOTE® HP-300 was submitted for stringent hydrogen compatibility testing at HyCentA Hydrogen Testfield—Europe’s premier hydrogen research and testing facility. The product underwent tests simulating SAE J2601 hydrogen refueling conditions at pressures up to 70 MPa inside Type IV hydrogen tanks.

The lubricant showed zero adverse effects on hydrogen purity, as confirmed through further laboratory analysis by Boltzmann Gas- and Materiallab using advanced IMR EI MS and FTIR spectroscopy.

Result: HP-300 fully complies with the ISO 14687:2019 Grade D purity standard.

Benefits for Hydrogen System Operators & OEMs in Europe

For European companies involved in the hydrogen supply chain—whether building refueling stations, producing fuel cell vehicles, or managing hydrogen-powered industrial assets—HP-300 offers:

✅ Compliance with EU and global hydrogen purity standards

✅ Operational safety, reducing the risk of catalyst degradation and system failures

✅ Extended service life, lowering maintenance costs and downtime

✅ Versatile use in extreme environments, where both chemical resistance and thermal stability are critical

The DGE Advantage – Expertise and Support for Hydrogen Applications

As the exclusive European distributor of MOLYKOTE® specialty lubricants, DGE brings decades of technical experience to customers navigating the complexities of hydrogen systems. Our team is ready to assist with:

- Technical consultations for hydrogen system lubrication

- Product selection support tailored to extreme environmental needs

- Supply chain reliability, ensuring you receive certified products when and where you need them

FAQS About MOLYKOTE® HP-300

Is MOLYKOTE® HP-300 Grease safe for use in oxygen-rich environments?

Yes. MOLYKOTE® HP-300 Grease is formulated with perfluoropolyether (PFPE) and a fluorinated polymer, offering exceptional oxidation stability and low vapor pressure. This makes it suitable and safe for use in oxygen-rich environments and high-vacuum applications where material volatilization is critical.

Can MOLYKOTE® HP-300 be used in cryogenic applications?

Yes. With a service temperature range from -65°C to +250°C, MOLYKOTE® HP-300 Grease performs reliably in cryogenic and extreme temperature conditions, where conventional lubricants may fail.

Ready to Future-Proof Your Hydrogen Applications?

MOLYKOTE® HP-300 Grease is now certified and available across Europe through DGE’s distribution network.

📩 Contact our technical team today to learn how HP-300 can optimize safety, compliance, and performance in your hydrogen infrastructure.