MOLYKOTE® HP-300 Grease protects critical inverter electrical connections

Case study: With reliable rubber compatibility and thermal regulation, grease lubricates and seals O-rings

The application

Electric vehicles depend on AC/DC power inverters to change the direct current (DC) electrical output from the vehicle’s battery into alternating current (AC) to power the engine and other components. These batteries supply 500 volts of power and a maximum current of 500 amps, so reliable inverter operation is key to protecting battery life and the vehicle’s motor.

The challenge

Power cables with O-ring seals made from various rubbers – including EPDM or silicone rubber – are used to connect the inverter and battery. The O-rings are critical to helping prevent moisture from entering the inverter chamber. With working temperatures reaching up to 120°C, wide-temperature performance and proper rubber-compatible lubrication is required to protect the O-rings from damage.

A vehicle manufacturer in China approached the MOLYKOTE® team for a solution that would deliver needed O-ring protection and performance, along with dependable rubber compatibility.

The solution

MOLYKOTE® HP-300 Grease can protect electrical connection O-rings in demanding environments, with minimal hardening or changes to mechanical properties. Delivering excellent rubber compatibility, performance and thermal stability, the grease is suitable for use with various rubbers, such as EPDM elastomers and silicone rubbers.

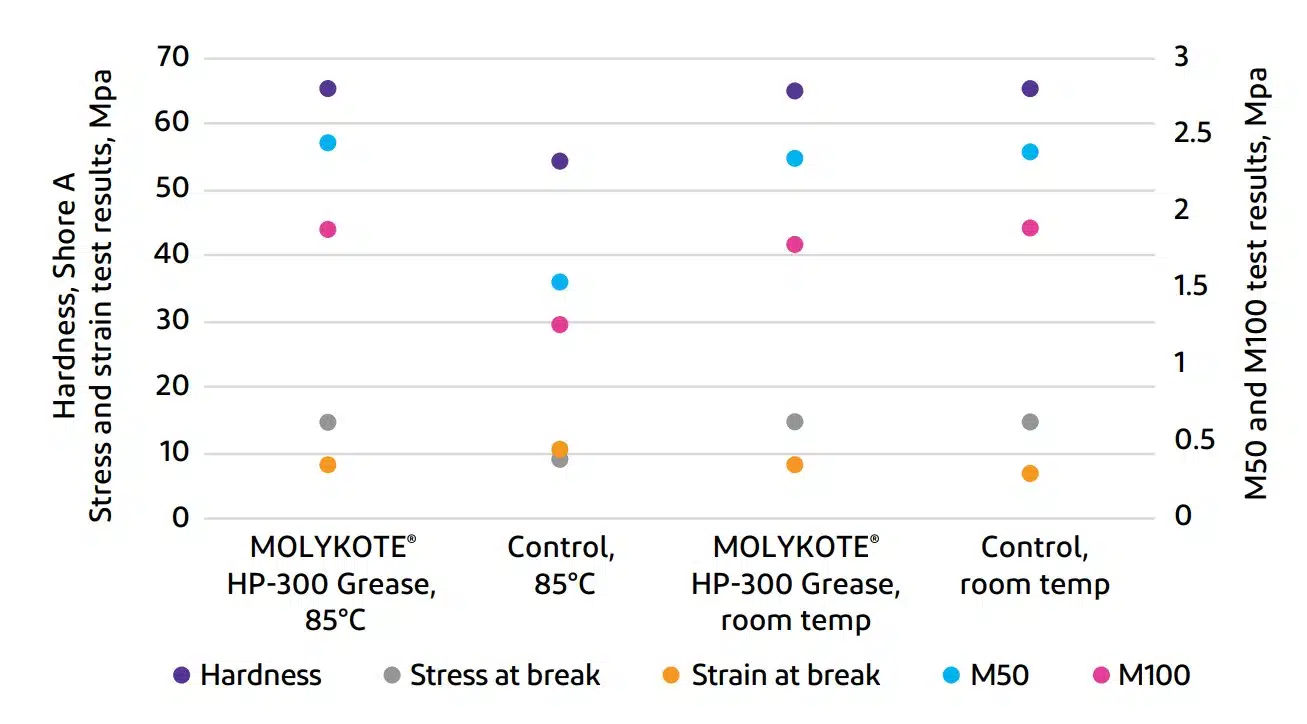

Using both EPDM elastomers and silicone rubbers, the MOLYKOTE® technical team subjected MOLYKOTE® HP-300 Grease to several tests to observe how the lubricant performed under pressure, successfully demonstrating the grease’s performance via lab comparisons with a traditional lubricant solution as a control. MOLYKOTE® HP-300 Grease did not negatively affect the mechanical properties of the rubber O-rings, and it showed excellent compatibility. The data convinced the automotive manufacturer that MOLYKOTE® HP-300 Grease was the right solution for its challenge.

EPDM elastomer compatibility tests

Specimens were prepared according to ISO 527 and were aged for 250 hours under 85°C and room temperature conditions.

Silicone rubber compatibility tests

Specimens were prepared according to ISO 527 and were aged for 250 hours under 85°C and room temperature conditions.

![]()

Get extraordinary performance in extreme conditions

MOLYKOTE® HP-300 Grease can be used broadly under harsh conditions, such as at low or high temperatures; in corrosive environments; in the presence of solvents, liquefied natural gasses and high-vacuum conditions; and more.

It has been used in specialized applications where the volatilization of the lubricating material is undesirable, such as on cleanroom equipment and semiconductor manufacturing equipment.

MOLYKOTE® HP-300 Grease delivers:

- Good plastic and rubber compatibility

- Excellent stability at high temperatures

- Superior resistance to chemicals and solvents

- Minimal deterioration due to oxidation; appropriate for long-term lubrication

- Low vapor pressure (base oil)

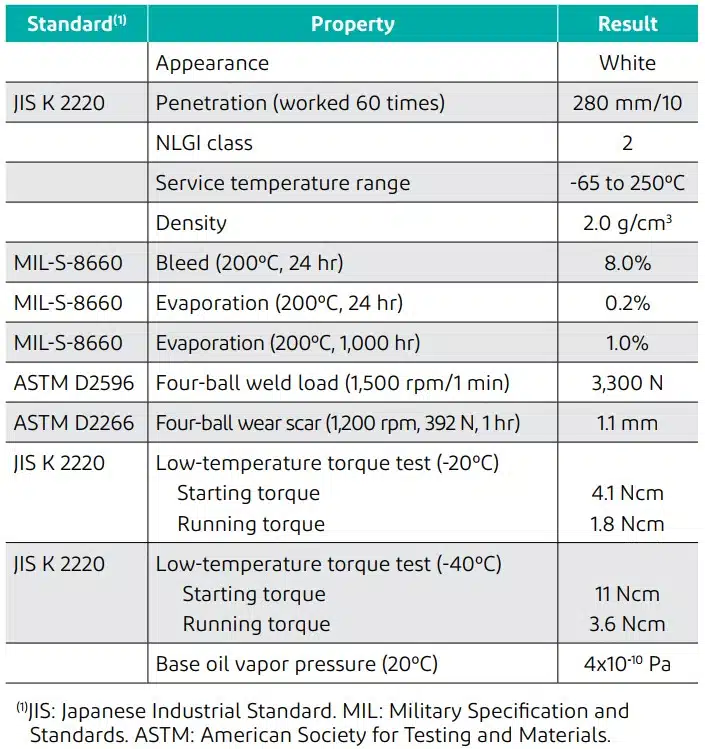

Typical properties of MOLYKOTE® HP-300 Grease

Note: These values are not intended for use in preparing specifications.

Source: MOLYKOTE® case study