Silicone Dispensed Foam Gaskets : Sealing and Gasketing

With the information below you will be able to introduce yourself into the Silicone Dispensed Foam Gaskets world.

40+ Years of Silicone-based Solutions

Agenda

Dispensed silicone discussion – gaskets and seals terminology

- Unique properties of silicone

- What are silicone dispensed foam gaskets (DFG)?

- Common applications

- Design considerations

- Equipment requirements for DFG

- Questions/discussion

Unique Properties of Silicones

- Performs in temperatures from -70 to 200˚C

- Withstands weathering, ozone, corona, radiation, moisture, chemicals, weak acids and bases, oils and fuels

- Operates in automotive, aerospace and general industrial applications

- Chemically inert

- Physical properties can provide high tensile, tear, modulus, elongation, fatigue life, resilience, damping and compression set

- Provides low flammability and smoke

- Provides extended low temperature performance and low swell in fuels (fluorosilicones)

- Heat curing (HTV) and room temperature curing (RTV) materials allow for flexibility in design

Dispensed Foam Gasketing (DFG)

What is Dispensed Foam Gasketing?

- Two-part foam dispensed directly on a component and cured

- Platinum-catalyzed, room temperature or heat cure, 1:1 mix ratio

- Self-foaming – does not require an added blowing agent o Provides a low modulus sealing option.

- Typically used where the part needs to be serviceable

When to use Dispensed Foam Gasketing

- Seal in/out air, dust, dirt, water

- Low modulus needed for plastic parts

- Low compression set needed o Squeak and rattle elimination (NVH)

Chemistry

Hydrosilation (Addition Cure)

- Accelerated by heat

- No by-products

- Catalyst easily poisoned

- Variable pot life

Curing of Silicone Foams from Dow

When the A and B components are mixed, the following reactions occur:

- Hydrogen formation

- Formation of gas cells and cell growth (foam expansion)

- Curing (formation of the elastomeric network)

All reactions are temperature-dependent but at different rate constants

To ensure a homogeneous cell size distribution, a proper mixing of the components and proper dispense tip selection are essential

Foaming mechanism:

- DFG products from Dow create the foaming gas during the crosslinking reaction (hydrogen as by-product)

- Typical amount of H2 evolved: 0.5-1.3 g/kg product (based on “worst case” consideration using low density 8257 foam)

- Typical expansion ratio: 1:2.5 to 1:4

- To ensure optimal foam structure a good mixing of the components is required

- In case of dynamic mixing air nucleation is typically recommended

DFG Applications

Typical Automotive Applications:

- ABS brake modules

- Power distribution/ECU Modules

- Filter housings

- Beauty covers

- Transportation inspection covers

- Thermostat housing

- Timing chain and timing belt covers

- Wheel cover

- Exterior lighting

- NVH/acoustic

CIPG/DFG: Primary Design Considerations

- Bead design

- Aspect ratios

- Flange groove/void volume design

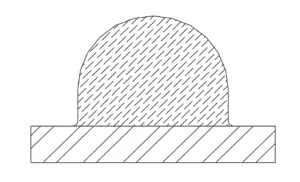

Gasket Bead Design

Generally limited to rounded, hump shape

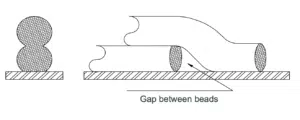

Aspect Ratio

Potential issues with high aspect ratios:

- Leaves small area for adhesion

- Could have roll-over tendency

High aspect ratios can contribute to bad knit lines

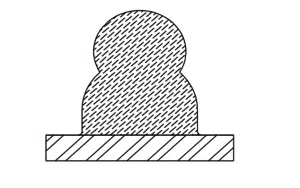

CIPG/Non-slump Silicone Dispensed Foam Gaskets Designs

DFG Special Situations

Stacked beads may be possible if using SILASTIC™ 3-8186 Thixotropic Foam due to low slump nature of the material.

Processing

CIPG and DFG typically require:

- Fixturing

- Meter/mixing o Robotic dispensing o Oven curing

Can be manual or highly automated for mass production

Typical Layout of a Production Line: DFG/CIPG

Processing

Fixturing:

- Good fixturing is critical for repeatable/accurate dispensing

- Corrects for part-to-part variation

- Maintains part alignment

- Poor fixturing leads to irregular gasket beads

Typical meter/mix dispense systems contain:

- Material feed pumps

- Teflon-lined stainless steel flex hoses

- Material filters

- Pressure regulators

- DC Servo motor rod-displacement metering (preferred)

- Air operated dispense gun, and static mixer elements

Robotic Dispensing:

Multiple dispensing axis depending on part complexity; robot provides an even, accurate and repeatable gasket bead with high throughput

Dispense Options:

- Articulated arm

- Cylindrical (SCARA)

- XYZ gantry

- Oven curing is typically used to cure the seal materials*

-

- Basic oven types:

- Infrared

- Gas fired

- Electric heated

- Basic oven types:

- Any method that heats the seal material is acceptable, heat is the important factor

*Except for DOWSIL™ 3-82XX series dispensed foams

Typical CIPG/DFG Application Cell

Summary: Main Considerations for Sealing and Gasketing

Does this part need to be serviceable?

-

- Yes: CIPG, DFG

- No: FIPG

Does this gasket need to seal in fluids (oil, coolant, etc.)?

-

- Yes: CIPG, FIPG

- No: DFG

Does the gasket need to seal in pressure?

-

- Yes: CIPG, FIPG

- No: DFG

Is there capital for equipment? Y/N?

How many parts*?

-

- 100,000 or less usually FIPG

- 100,000 or more, CIPG, DFG

*Ball-park numbers – simply used for reference