Imagine Improved Thermal Management, Reliability and Cost-Effectiveness for Electric Vehicle Applications

Designs for the Future … Today

The market for plug-in hybrid and battery-powered electric vehicles (xEV) has the potential to grow exponentially in the coming years. But realizing that potential will depend on a number of factors, including the industry’s ability to meet consumer expectations for performance and value.

This will challenge battery makers to design for the large- volume production of lithium battery packs that are smaller, lighter and less expensive. These higher-energy-density packs will be capable of delivering more power, longer, through better thermal control.

Manufacturers and designers of other xEV components – including battery management systems, power control units, DC/DC converters and electric motors – face many of the same thermal management, assembly and protection challenges. Dow can help, with an extensive portfolio of proven, innovative and emerging silicone technologies for xEV applications.

![]()

Silicone Advantages for Electric Vehicle Applications

The properties that have enabled silicone materials from Dow to excel in a wide range of PCB system assembly, such as through-hole PCB assembly, and automotive applications could prove invaluable in helping you address challenges associated with designing and producing large volumes of lithium battery systems and other components for the electric vehicles of tomorrow:

- Very low thermal resistance

- Flow, wetting, adhesion and cure properties that can help speed and simplify processing

- Excellent thermal stability – wide operating temperature range

- Reliable performance under harsh conditions – resistance to thermal shock, oxidation, moisture and chemicals

- Excellent electrical insulation (dielectric strength)

- Excellent stress relief

![]()

Enabling & Problem-Solving Silicone Materials

Silicone is an amazingly versatile material that can be produced in many forms. Dow is a silicone pioneer and a global leader in engineering silicones to meet specific performance and processing requirements.

Silicone is an amazingly versatile material that can be produced in many forms. Dow is a silicone pioneer and a global leader in engineering silicones to meet specific performance and processing requirements.

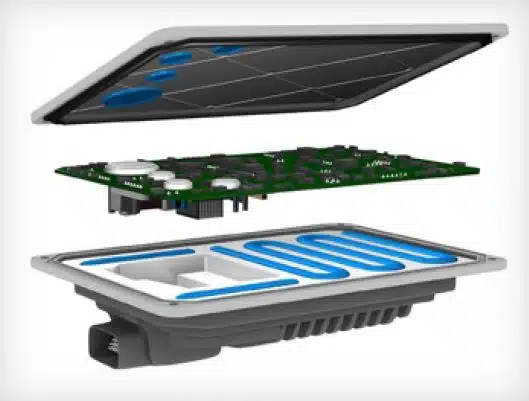

For Thermal Management

Thermally conductive silicone materials from Dow have properties that can help you reduce operating temperatures and extend the life and performance of batteries and other electric vehicle PCB system components. We offer a wide range of thermal interface materials with the potential for creating effective, efficient designs and assembly applications. You also can opt for using a humiseal coating on your PCB components as this will keep them protected for use.

Examples of leading technologies include:

- Thermally conductive silicone adhesives for coupling the battery pack to the heat sink; also may be appropriate for use within or between cells

- Noncuring thermally conductive silicone compounds, with a possible applied temperature range of -40 to 150 C, for conducting heat from the battery cells to the heat sink

- Thermally conductive silicone gels and encapsulants are flowable materials that facilitate high-volume processes in automated production; can be used as an alternative to precured pads to couple cells and modules to heat sinks or as conformable gap-fillers.

For Other Challenges

Dow offers proven and innovative materials to help you meet a wide range of electric vehicle application challenges.

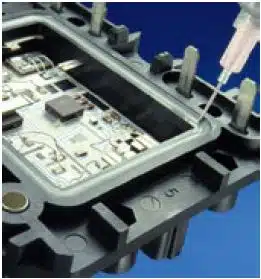

- Silicone gels for potting of PCB circuitry in the battery pack’s power management system

- Adhesives for a variety of bonding applications, including staking large capacitors for vibration control, extra support for large components on circuit boards, and housing sealing

- Conformal coatings for protecting printed circuit boards in the power management system

- Engineered elastomers for heat-resistant sealing and gasketing

Breakthrough Technologies to meet needs for performance, design flexibility and cost control

![]()

DOWSIL™ EA-7100 Adhesive

A Thermal Radical Cure™ adhesive for use in the assembly of circuitry housings and for attaching connectors, control units or sensors to substrates.

DOWSIL™ EA-7100 Adhesive cures much faster at moderate temperatures than conventional heat-curable silicones, and it may allow you to eliminate some cleaning steps, enabling faster throughput and lower energy costs. Plus, it offers durable adhesion to a broad range of diverse substrates for greater design flexibility. Other quality- and performance-enhancing benefits include adhesion in harsh environments, low void formation, superior anti-corrosion performance and less sensitivity to contamination.

DOWSIL™ TC-4525 Gap Filler

A cost-effective way to manage the rising heat in next-generation PCB system assemblies.

DOWSIL™ TC-4525 Gap Filler is a soft and compressible silicone material designed to dissipate heat from PCB system assemblies. This high- performing new silicone technology deliversthermal conductivity of 2.5 W/m.K, greatly improved dispensability and stable performance for more reliablecircuitry in harsh automotive underhood environments.

xEV Battery Pack

Thermal Management

Thermally Conductive Gap Fillers

- DOWSIL™ TC-4515 Gap Filler

- DOWSIL™ TC-4525 Gap Filler

- DOWSIL™ TC-4525 GB Gap Filler

- DOWSIL™ TC-4525 CV Gap Filler

- DOWSIL™ TC-4529 Gap Filler

Thermally Conductive Adhesives

- DOWSIL™ TC-2030 Adhesive

- DOWSIL™ TC-2035 Adhesive

- DOWSIL™ SE 4485 Thermally Conductive Adhesive

- DOWSIL™ SE 4485 L Adhesive

- DOWSIL™ SE 4486 Adhesive

Thermally Conductive Encapsulants

- DOWSIL™ TC-4605 Encapsulant

- DOWSIL™ TC-4605 HLV Encapsulant

Assembly

Adhesives

- DOWSIL™ EA-5151 Assembly Adhesive

- DOWSIL™ 7091 Adhesive Sealant

- DOWSIL™ SE 9168 RTV Adhesive

- DOWSIL™ SE 9185 Clear or White Adhesive

- DOWSIL™ EA-1236 Base and Catalyst Special Adhesive

Silicone Foam

- DOWSIL™ 3-8209 Silicone Foam

Connector

Encapsulants

- SYLGARD™ 170 Silicone Elastomer

- SYLGARD™ 170 Fast Cure Silicone Elastomer

- SYLGARD™ 567 Primerless Silicone Encapsulant

Adhesive

- DOWSIL™ SE 9186 Clear or White Sealant

Silicone Foam

- DOWSIL™ 3-6548 Silicone RTV Foam

Battery Management System (BMS)

PCB Protection

Conformal Coatings

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-1965 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

Power Control Unit (PCU), Including Inverter, Converter, Etc.

Thermal Management

Thermally Conductive Compounds

- DOWSIL™ TC-5026 Thermally Conductive Compound

- DOWSIL™ TC-5625C Thermally Conductive Compound

- DOWSIL™ SC 4471 CV Thermally Conductive Compound

Thermally Conductive Gap Fillers

- DOWSIL™ TC-4515 Gap Filler

- DOWSIL™ TC-4525 Gap Filler

- DOWSIL™ TC-4525 GB Gap Filler

- DOWSIL™ TC-4525 CV Gap Filler

- DOWSIL™ TC-4529 Gap Filler

Thermally Conductive Adhesives

- DOWSIL™ Q1-9226 Thermally Conductive Adhesive

- DOWSIL™ 1-4174 Thermally Conductive Adhesive

- DOWSIL™ TC-2030 Adhesive

- DOWSIL™ TC-2035 Adhesive

Assembly

Adhesives

- DOWSIL™ EA-7100 Adhesive

- DOWSIL™ EA-5151 Assembly Adhesive

- DOWSIL™ EA-6060 Adhesive

- DOWSIL™ 3-6265 Thixotropic Adhesive

- DOWSIL™ 3-6265 HP Adhesive

- DOWSIL™ 3-1598 HP Adhesive

- DOWSIL™ 866 Primerless Silicone Adhesive

- DOWSIL™ 7091 Adhesive Sealant

- DOWSIL™ 744 RTV Sealant

- DOWSIL™ EA-1236 Base and Catalyst Special Adhesive

Silicone Foam

- DOWSIL™ 3-8209 Silicone Foam(6)

CIPGs (Cured-in-Place Gaskets)

- SILASTIC™ RBL-9694-20P A&B Liquid Silicone Rubber

- SILASTIC™ RBL-9694-30P A&B Liquid Silicone Rubber

- SILASTIC™ RBL-9694-45M A&B Liquid Silicone Rubber

PCB Protection

Conformal Coatings

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-1965 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

Electric Motor

Protection

Thermally Conductive Encapsulants

- DOWSIL™ CN-8760G Encapsulant

- DOWSIL™ TC-4605 Encapsulant

- DOWSIL™ TC-4605 HLV Encapsulant

Conformal Coatings

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-1965 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

- DOWSIL™ LDC 2577 D Dispersion Coating

Control Unit Thermal Management

Thermally Conductive Encapsulants

- DOWSIL™ TC-6020 Thermally Conductive Encapsulant

On-Board Charger

Thermal Management

Thermally Conductive Encapsulants

- DOWSIL™ TC-4605 Encapsulant

- DOWSIL™ TC-4605 HLV Encapsulant

- DOWSIL™ TC-6020 Encapsulant

Assembly

Adhesive

- DOWSIL™ EA-9189 H RTV Adhesive

Protection

Conformal Coatings

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-1965 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

PTC Heater

Thermal Management and Assembly

Thermally Conductive Adhesives

- DOWSIL™ Q1-9226 Thermally Conductive Adhesive

- DOWSIL™ SE 4402 Adhesive

- DOWSIL™ TC-2035 Adhesive

Electric Compressor

Protection

Conformal Coatings

- DOWSIL™ 3-1953 Conformal Coating

- DOWSIL™ 3-1965 Conformal Coating

- DOWSIL™ 1-2577 Low VOC Conformal Coating

Sheath Heater

Protection

Encapsulants

- SYLGARD™ 170 Silicone Elastomer

- SYLGARD™ 170 Fast Cure Silicone Elastomer

Download the Selection Guide

The Value of Materials Innovation, Expertise and Support from Dow ![]()

Established specifically to explore and develop the potential of silicones, Dow has grown to be a global leader in silicones, silicon-based technology and innovation. We bring you:

- More than 65 years of success in game-changing materials innovation for the world’s transportation industry

- Specific expertise in the development of performance-enhancing and enabling technologies for automotive applications

- Decades of experience in the development and application of silicone-based thermal management materials

To help make electric vehicles a high-performing, cost-effective transportation alternative, Dow is investing in new solutions for the design and assembly of xEV applications. And we are looking for opportunities to collaborate with battery cell makers, system designers, assemblers, tier suppliers and vehicle OEMs to improve the efficiency and reliability of next-generation battery packs and systems.

How Can We Help You Today?

Tell us about your performance, design and manufacturing challenges. Let us put our silicon-based materials expertise, application knowledge and processing experience to work for you.

For more information about our materials and capabilities or to discuss how we could work together to meet your specific needs contact DGE.