Ensuring the safety and quality of food and beverage manufacturing processes is paramount, necessitating the use of lubricants that won’t compromise the integrity of products. Imagine your favorite soft drink being tainted during production by a hazardous substance; that initial sip would be far from enjoyable and could even pose health risks depending on the chemical composition! So, how are the standards for food, water, and consumer products upheld? Enter NSF International, an independent global organization committed to safeguarding these standards.

What exactly does it mean when a lubricant is labeled “NSF H1 Certified”?

This certification indicates the highest level of food safety, signifying that the lubricant is suitable for applications where incidental contact with food may occur (up to 10 ppm). These H1-certified lubricants are odorless, tasteless, and chemically inert, ensuring efficient lubrication without the risk of product contamination.

And “NSF H2 Certified”?

Moving down a notch, we have “NSF H2 Certified” lubricants. These are designated for use in equipment that doesn’t directly interact with food, such as forklifts or out-of-room compressor systems. NSF H2 lubricants undergo rigorous refinement processes and are strictly prohibited from containing carcinogens, heavy metals, mutagens, mineral acids, or any other potentially harmful substances.

For companies involved in food and beverage production, ensuring customer safety and product quality is non-negotiable. That’s where MOLYKOTE® Food-Grade Lubricants come into play, offering easy-to-use solutions that meet rigorous food safety standards, providing peace of mind for manufacturers and consumers alike.

Food Grade Lubricants: superior emulsification resistance

DuPont MOLYKOTE® lubricants are meticulously crafted at the molecular level to achieve maximum saturation, effectively eliminating potential nucleation sites within the structure that could foster bonds with water. This intrinsic resistance to water endures throughout the lubricant’s lifespan, ensuring exceptional protection for equipment subjected to frequent washing and rinsing, all while maintaining peak lubricant performance.

Expansive Temperature Range – From Deep Freeze to Intense Heat

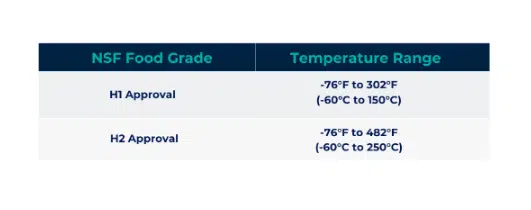

In the food and beverage industry, where operations often encounter extreme temperature variations, MOLYKOTE® performance lubricants offer a diverse selection of H1 and H2 formulations with extensive temperature stability:

Highly Refined for Premium Quality and Value

Renowned for their exceptionally refined and cutting-edge base stocks, MOLYKOTE® High-Performance Lubricants deliver a myriad of tangible benefits in demanding manufacturing environments, including:

- Extended Drain Intervals: Reducing lubricant consumption and expenses.

- Cleaner and Longer Operation: Enhancing equipment longevity and minimizing maintenance needs.

MOLYKOTE® Food Grade

Comprising performance oils, greases, and pastes tailored to meet stringent food safety standards.