New Dowsil’s solution for Battery Pack Assembly

Dowsil has developed a new product for Battery Pack Assembly. All related information is specified below.

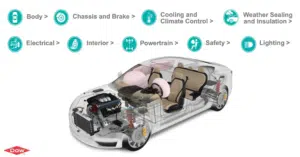

• Dow Performance Silicones Portfolio

― Silicones in Standard Vehicles

― Battery Assembly

• Why Silicone?

• Advancing Your Battery Assembly

• Thermal Management

• Thermal Isolation

• EMI Shielding

• Conformal Coatings

Performance Silicones Portfolio

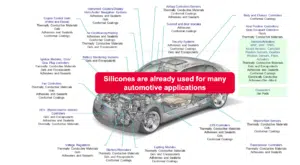

Silicones in standard vehicles

Why Silicone for Battery Applications?

Thermal Stability

- High temperature resistance

- Wide temperature range retention of elastomeric properties

Tunable: Modulus/Hardness/Cure chemistries

- Hardness range from hard to soft depending on application

- Flexible/compliant, retains flexibility at high filler (thermal, electrical) content with high elongation at break

- Fast RT cure for large component fixing and increased productivity

Thermal management performance

- Wide thermal conductivity range available

- Silicone provides low thermal resistivity

Thermal event isolation

- Slow the spread of thermal events in lithium ion battery

Light weighting

- Silicone foams meet UL requirements with low weight

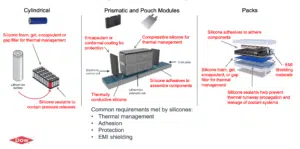

Silicones in Battery Pack Assembly

Battery Pack Assembly

Assembly and integration of EV/HEW batteries and modules require mechanical fixing, thermal management and vibration damping. We provide DOWSIL solutions for all of these applications.

Silicone-based materials enable customers to cost-effectively manage the challenges in their next-generation EV/HEV battery assembly designs.

Advancing your Battery Pack Assembly

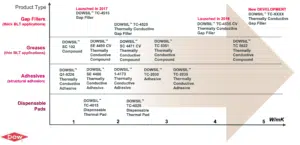

Portfolio of Advanced Thermally Conductive Materials: Focus on Gap Fillers

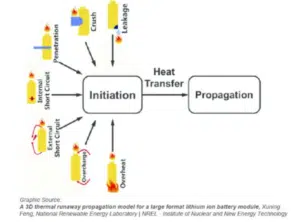

Introducing: thermal runaway propagation prevention

- Silicones can slow the spread of thermal events in lithium ion battery applications

- Filled or unfilled silicones available:

- Gap fillers

- Foams

- Encapsulants

- Gels

- Application requirements determine material selection

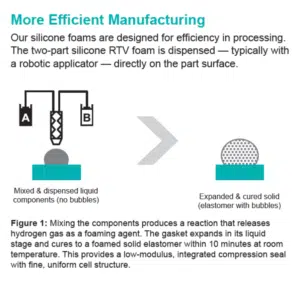

- Silicone foams can be a light weight alternative to traditional encapsulant and sealant options.

- Foam encapsulant can provide cell protection in the case of a thermal event.

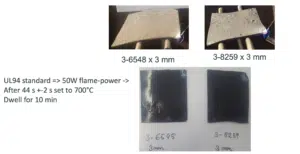

Silicone Foam flammability testing

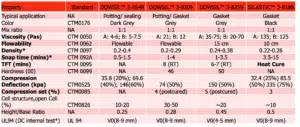

Dow Silicone Foam Products – Commercially Available

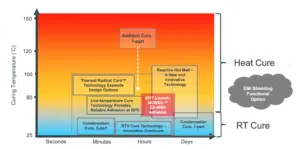

Introducing: EMI Shielding

Increasing density of electronic components in many market segments.

Shielding prevents cross-talk of electronic circuits, detectors, RF signals.

Silicones provide flexibility over a wide range of temperature and environmental conditions

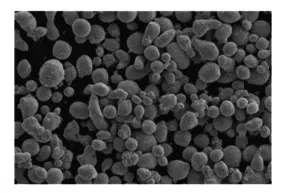

Electrically Conductive Silicones

- Formulation.

- Polymer- Able to tune rheology, mechanical performance, adhesion, stability

- Filler- Electrical performance, rheology, cost, stability

- Additives- Cure dynamics, stability, shelf life

- Characterization Mechanical

- Electrical

- Chemical

- Application testing

- Dispensing

- Accelerated stress testing

- Electro-mechanical characterization

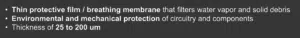

Conformal Coatings

Key Benefits

- Improves reliability in humid environments.

- Protects PCBs and other electronic components against environmental particles, moisture and contaminants, preventing sort circuits nd corrosion of conductors and solder joints

- Protects circuits and components from abrasion and solvents

- Stress relieving

- Protects insulation resistance

- Reduces conductor spacing on PCBs

- Good dielectric properties (insulation, moisture resistance, breakdown voltage)

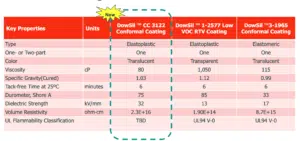

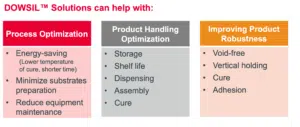

Conformal Coatings Solutions

Customer Satisfaction Starts with Design

And that is all the needed information about the new solution for Battery Pack Assembly. If you have any doubt, you always can contact us and we will help you.