Case study: Strain-wave gearbox lubrication with MOLYKOTE® G-1074 Grease

A leading, Europe-based manufacturer of tailor- made mechatronic actuator systems for automotive applications selected MOLYKOTE® G-1074 Grease to provide the high-performance lubrication needed on its advanced Active roll stabilizer suspension system relies on MOLYKOTE® Smart LubricationTM solution.

The system is designed and developed to reduce body tilt during cornering and hard turns, keeping the vehicle more level during such maneuvers to improve handling and safety. The initial application is on selected models of a luxury vehicle brand.

Faster-acting than typical hydraulically actuated roll stabilizers, the advanced electromechanical design incorporates a strain-wave gearbox, specially developed brushless motor and an electronic controller to influence torque coupling and dramatically reduce rolling movements of the vehicle. In evaluating potential lubricants for the stabilizer gearbox application, the manufacturer selected MOLYKOTE® G-1074 Grease for its superior performance compared to an initially qualified lubricant choice.

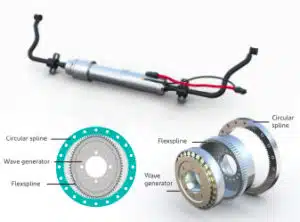

The active stabilizer uses a torsion spring to link the left and right sides of the vehicle. It combines a strain-wave gearbox, brushless motor and electronic controller.

The strain-wave gear set provides repeatable accuracy for positioning inertial loads with high torque. It consists of a circular spline ring gear, a flexspline cup and an elliptical-shaped wave generator that is slightly smaller than the flexible ring and has two fewer teeth. The flexspline deforms to the shape of the wave generator and works independent of the shaft. The flexspline rotates much slower than the wave generator and in the opposite direction.

Customer

A manufacturer of mechatronic actuator systems developed a backlash-free, high-reduction strain-wave gearbox for an active stabilizer suspension system being used on select models of a luxury- class vehicle brand. The company is a subsidiary of a world market leader in precision gears and actuator systems for robotics and for the railway, automotive and aerospace industries.

Challenge

To meet a vehicle OEM customer’s performance specifications, the manufacturer of the strain-wave gear technology needed an effective lubricant to outperform current PAO-based grease options. Key lubrication criteria included noise-damping capabilities, good lubricity with high-pressure sliding friction, good low-temperature performance, suitable grease mobility, and compatibility with gearbox elastomer seals.

Solution

The manufacturer collaborated with MOLYKOTE® brand application engineering specialists to identify an effective solution to meet the gearbox lubrication needs. Compared with an initial PAO/ester grease for gearbox lubrication, MOLYKOTE® G-1074 Grease delivered superior performance. Potential benefits included less noise, reduced

oil separation and oxidation, and good lubricity under extreme pressures across a wide temperature range.

Advantages of MOLYKOTE® G-1074 Grease

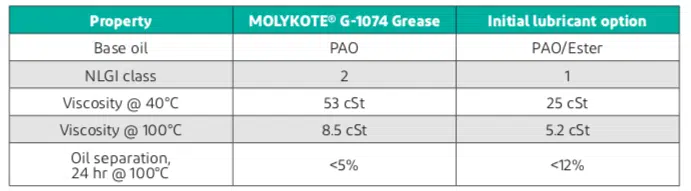

The performance properties of MOLYKOTE® G-1074 Grease compare favorably with those of the initial lubricant option for the gearbox application.

Gearbox lubricant property comparision

Potential advantages of MOLYKOTE® G-1074 Grease include:

- Better noise-reduction capabilities

- Reduced friction under extreme pressure at high frequency

- Less oil separation

- Better oxidation stability

Good lubricity over a wide service-temperature range

Excellent compatibility with H-NBR sealing elastomersBased on gearbox lubrication performance in the vehicle active suspension system, the manufacturer expects to qualify MOLYKOTE® G-1074 Grease for use in other actuator applications for robotics, farm machinery, autonomous vehicles, industrial control technologies and more. Based on industry interest, mechatronic roll stabilizer applications have sizable growth potential across multiple vehicle platforms.

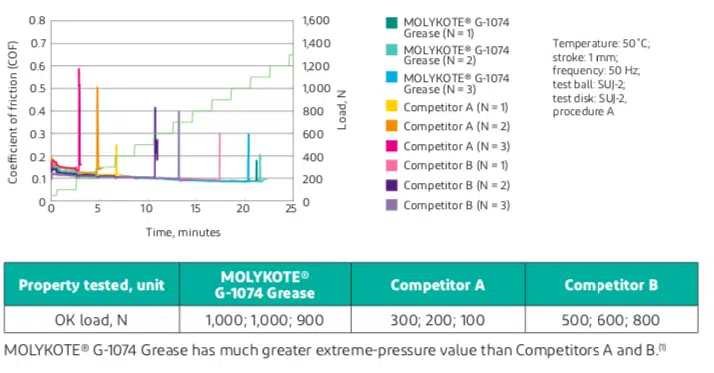

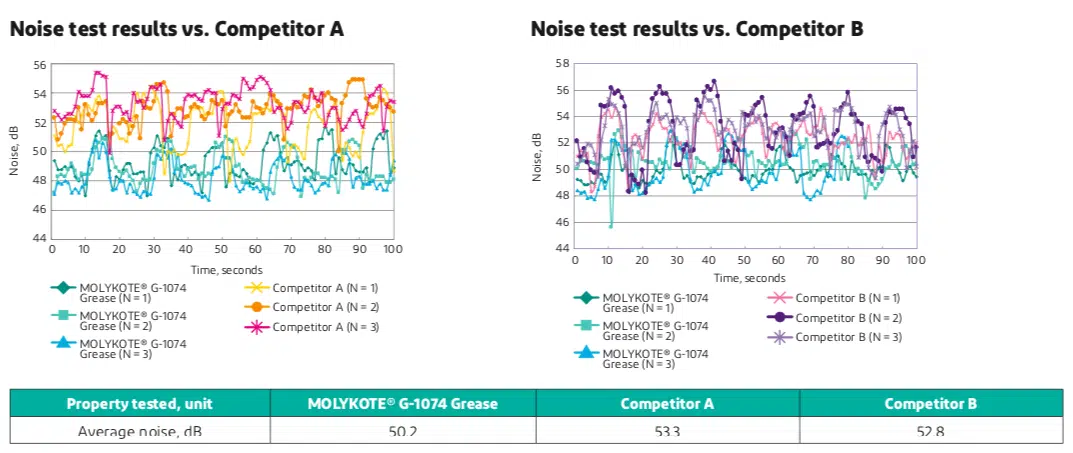

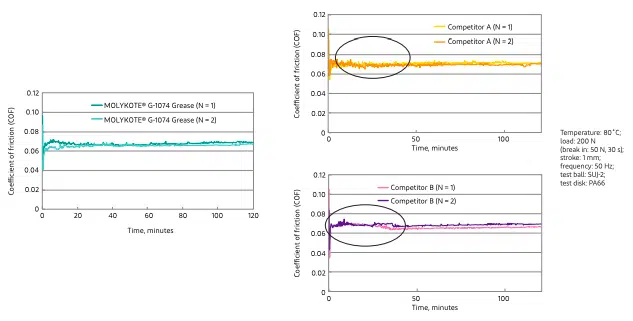

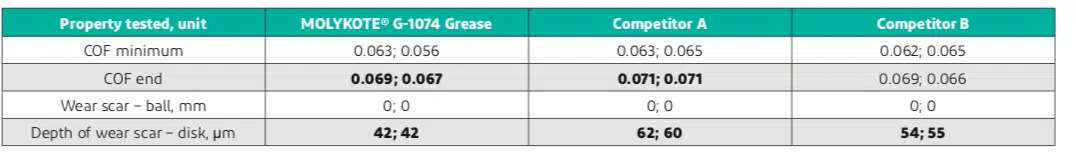

Comparative performance testing of the active roll stabilizer system

MOLYKOTE® G-1074 Grease has demonstrated superior capabilities over two different competitive lubricants in comparative performance testing. This technical data shows clear advantages in terms of reduced friction under extreme pressure, less noise generation and a more stable coefficient of friction. These test results provided the design team support for selecting MOLYKOTE® G-1074 Grease as the strain-wave gearbox lubricant.

SRV extreme-pressure test results

The strain-wave gearing works on elastic dynamics and utilizes the flexibility of metal. It offers excellent positioning accuracy and repeatability, high torque capacity, a wide range of reduction ratios (50:1 to 320:1) in the same package size, zero backlash, lightweight and compact designs, and coaxial input and output shafts.

Meeting the lubrication

Challenge

Faced with potential performance issues with its initial gearbox lubricant choice, the actuator system manufacturer requested help. Trust in the MOLYKOTE® brand – our specialty lubrication expertise, problem-solving capabilities and broad technical support – opened an opportunity

to evaluate an application-matched noise-damping grease.

MOLYKOTE® G-1074 Grease was identified as a potential solution to meet customer requirements for effective lubrication of the strain- wave gearbox used in the active roll stabilizer suspension system. This high-performance lubricant is formulated to provide excellent lubricity under extreme pressure, low noise, materials compatibility with most materials, and good flow characteristics across a wide service- temperature range. It consists of a polyalphaolefin (PAO) base oil, thickened with lithium soap and fortified with Polytetrafluoroethylene (PTFE) and antioxidant additives.

These values indicate that MOLYKOTE® G-1074 Grease will reduce noise by 30% more than Competitor A and will reduce noise by 26% more than Competitor B

SRV coefficient of friction test results: ASTM D5707

Compared to Competitor A, MOLYKOTE® G-1074 Grease shifted smoothly, while Competitor A had strong fluctuation until 20 minutes.(2) Compared to Competitor B, MOLYKOTE® G-1074 Grease shifted stably and smoothly, while Competitor B had large fluctuation until 20 minutes and COF slightly dropped in 30 minutes.

Other potential applications of active roll stabilizer system

With excellent noise-damping properties, high performance under extreme pressure at high frequency, and a wide service-temperature range, MOLYKOTE® G-1074 Grease offers significant performance advantages for use in other applications. Effective on most common metals, plastics and elastomers, this PAO-based grease is an excellent lubricant for bearings, gears, slides and other applications requiring low friction under heavy loads. It provides an effective solution for noise, vibration and harshness (NVH) control in automotive applications involving chassis and brake systems, as well as selected exterior or interior components.

Typical properties

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local MOLYKOTE® sales representative prior to writing specifications on this product.

|

Test method(3) |

Property |

MOLYKOTE® G-1074 Grease |

|

Appearance |

Translucent white |

|

|

Composition |

Polyalphaolefin (PAO), lithium soap, PTFE, antioxidants |

|

|

Service temperature range |

-40 to 150°C |

|

|

JIS K 2220 |

Penetration, worked 60 strokes @ 25°C |

280 |

|

JIS K 2283 |

Base oil viscosity @ 40°C @100°C |

53 mm2/s 8.5 mm2/s |

|

JIS K 5600 |

Density |

0.90 g/ml |

|

JIS K 2220 |

Bleed, 24 hours at 100°C |

3.6% |

|

JIS K 2220 |

Evaporation loss, 22 hours at 99°C |

0.1% |

|

JIS K 2220 |

Water washout, 1 hour at 38°C |

1.98% |

|

JIS K 2220 |

Dropping point |

210°C |

|

ASTM D2266 |

Wear scar, 4 ball test |

0.69 mm |

|

ASTM D5706 |

SRV, extreme pressure @ 50°C, 50 Hz, 1 mm, procedure A |

1,000 N |

|

JIS K 2220 |

Low-temperature torque at -40°C Starting |

90 mN•m 50 mN•m |

ASTM: American Society for Testing and Materials; JIS: Japanese Industrial Standard; CTM: Corporate Test Method.

Learn more about the active roll stabilizer: Contact us

To learn more about the advantages of MOLYKOTE® G-1074 Grease for strain-wave gearbox lubrication, noise- damping automotive NVH-control applications or other tough lubrication challenges, contact your MOLYKOTE® technical representative