DOWSIL™ EC-8425 is a new 1-part heat cure Electrically Conductive Adhesive for grounding, bonding and shielding interference applications with durable mechanical and conductive properties and reliable performance at high temperature and vibration.

Key benefits

- Durable mechanical and conductive properties

- Reliable performance that can withstand high temperature and vibration

- Strong adhesion

- Strong electromagnetic shielding across a wide range of frequencies

- Cure at medium temperatures (~90°C)

- 20% elongation at medium cure T° to enable flexibility at joints

- Balancing cost and performance

- Added UV indicator for ease of inspection

- Solvent-free

Automotive Applications

- EMI/EMC shielding

- Electrical connection – grounding

Targeting

- ADAS (Advanced Driver Assistance Systems) ▪ Inverter/Converter

- Electronic Control Unit

- Sensors

DOWSIL™ EC-8425 Electrically Conductive Adhesive

- Durable mechanical and conductive properties, reliable performance

- Withstands high temperature and vibration

- Balanced cost and performance enable use in wide variety of grounding applications

- Cure at medium temperatures ≥ 90 °C (gelation onset 80°C, 30 min)

- Greater than 20% elongation to enable flexibility at joints

- Potential applications include solder and mechanical fastener replacement

- Formulated with blend of silver & sliver platted filler

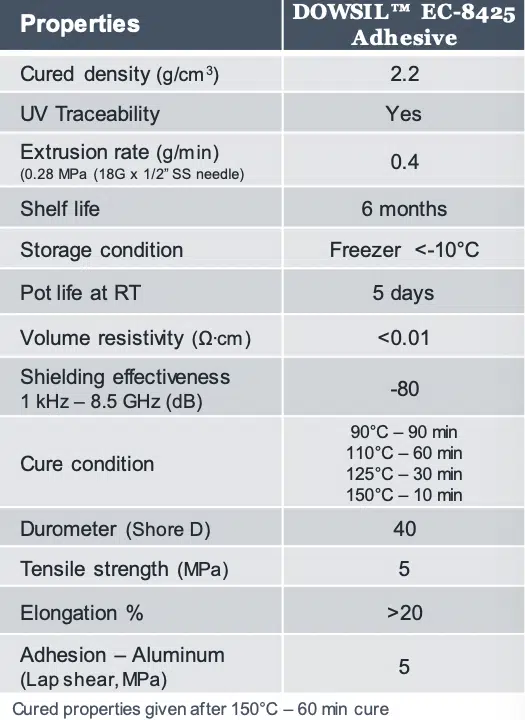

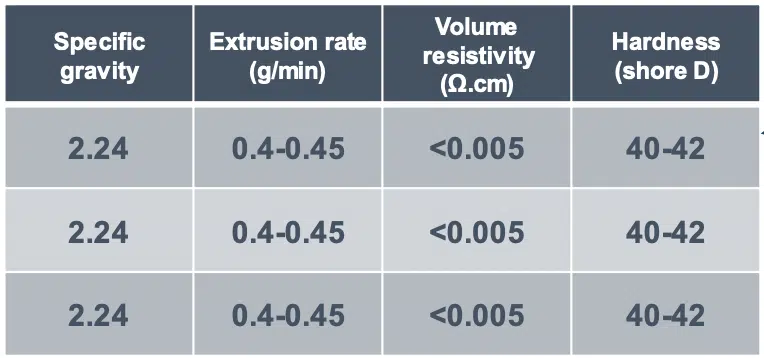

Properties

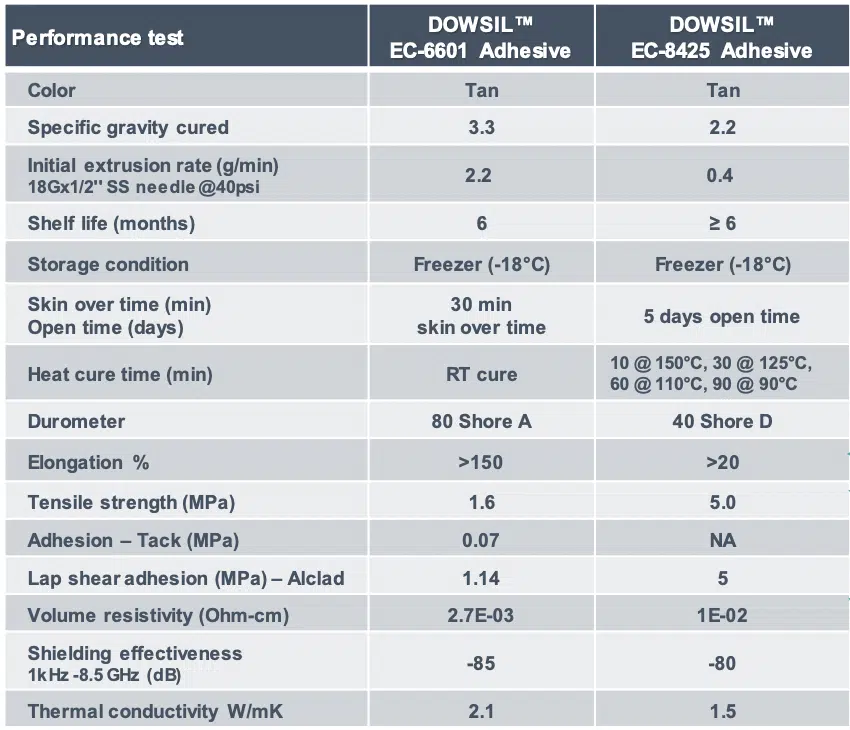

Property comparisons

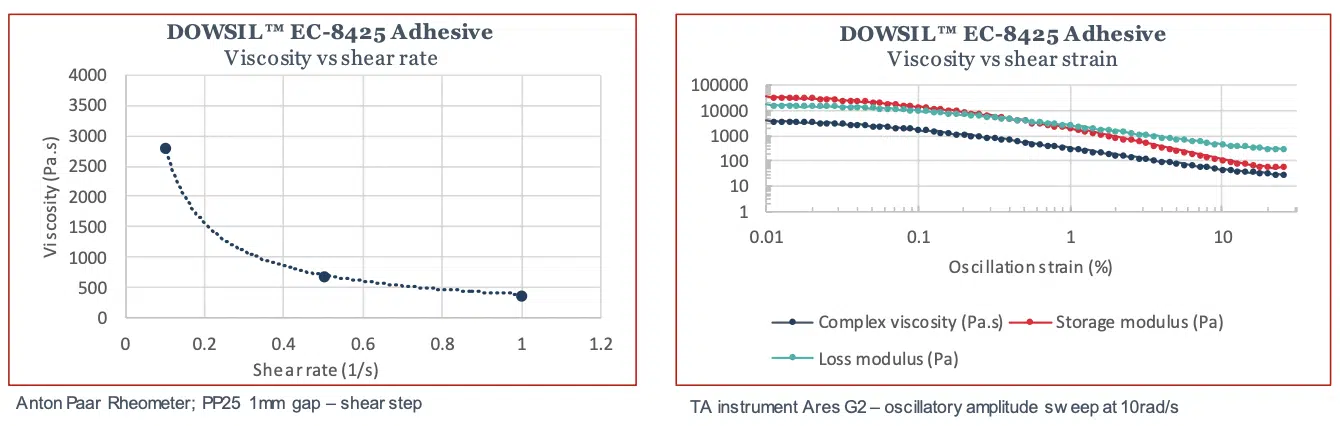

Adhesive rheology

Viscosity:

- 2800 Pa.s @ 0.1(1/s)

- 400 Pa.s @ 1 (1/s)

Thixotropic index (0.1/1): 7

Electrically Conductive Adhesive

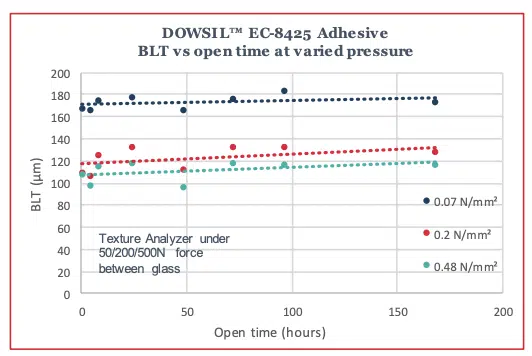

Open time

- >5 Days at room temperature

- Increase of viscosity/decrease of extrusion is leading factor

- Stable adhesion and bond line thickness

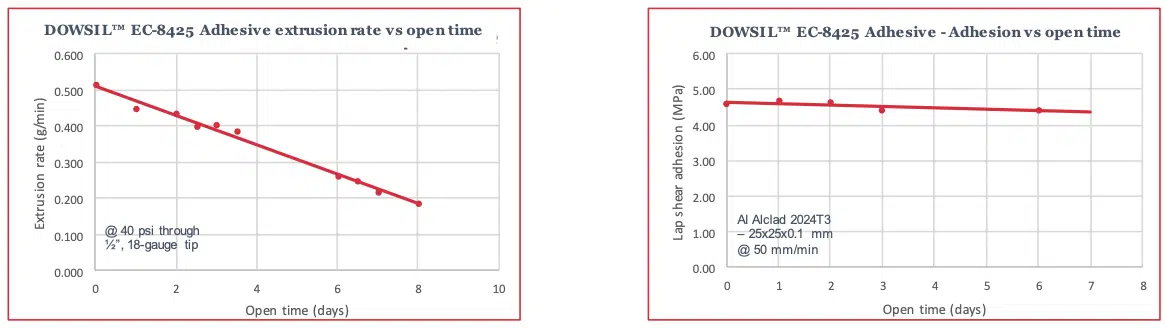

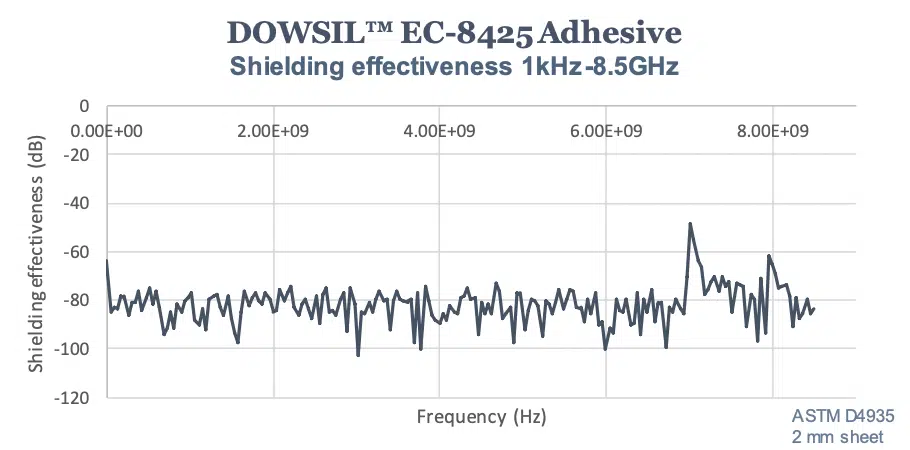

Adhesive cure properties

- Stable properties under various cure conditions

- Initial variation in adhesion vs cure condition recovered with time at cure temperature

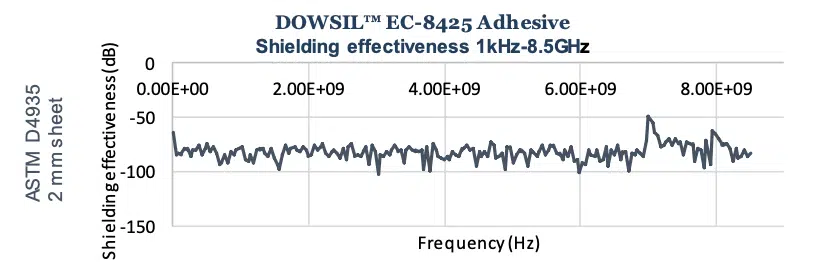

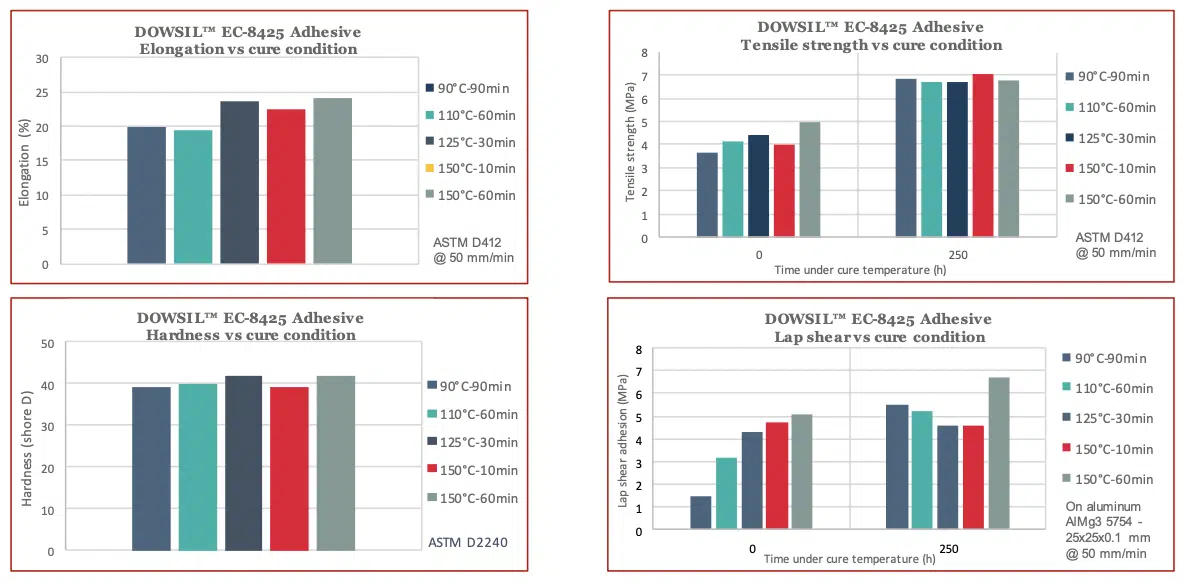

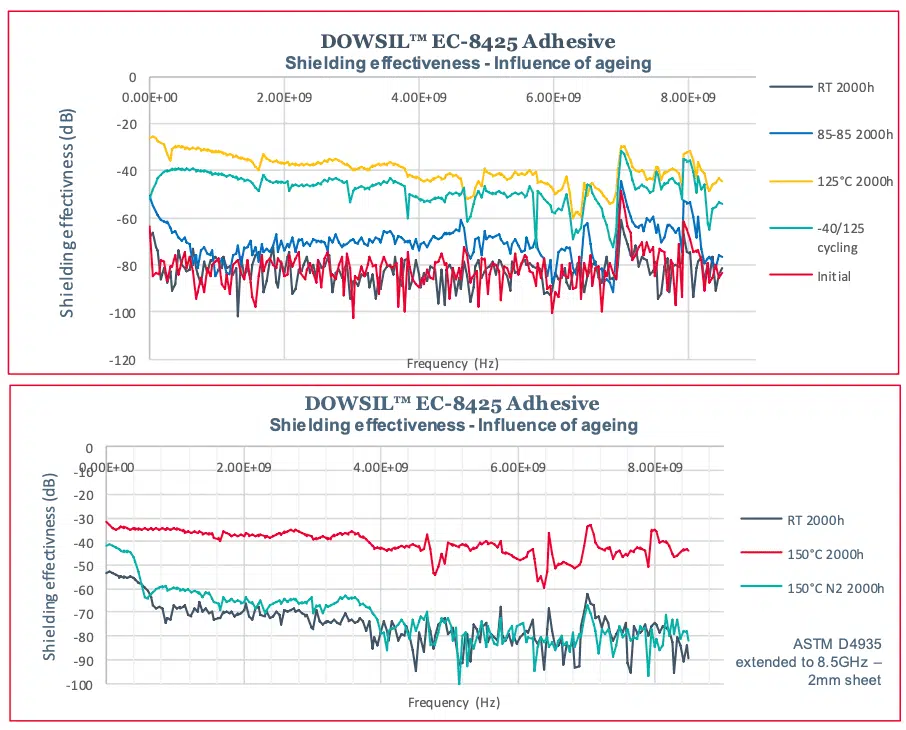

Adhesive shielding effectiveness

- Strong shielding across wide range of frequency

- Average -81dB (frequency range 100kHz-8.5GHz)

Electrically Conductive Adhesive

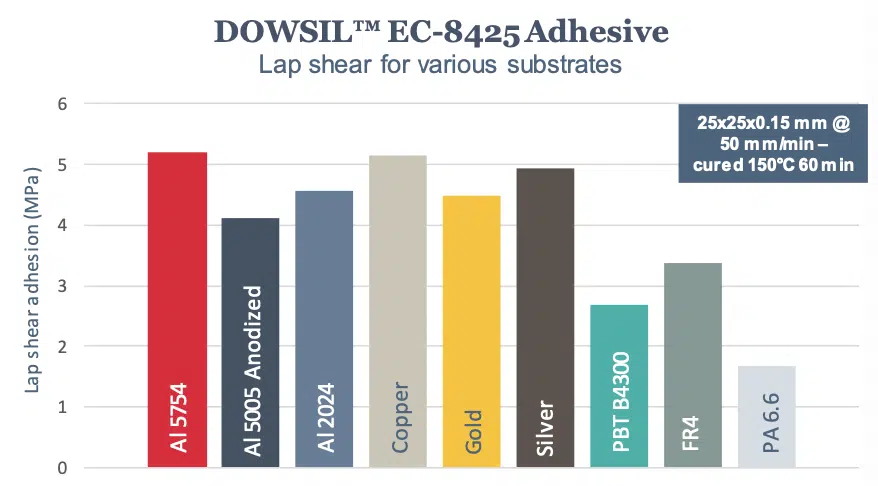

• Adhesion on wide range of substrate

• Enhanced adhesion on typical conductive substrat

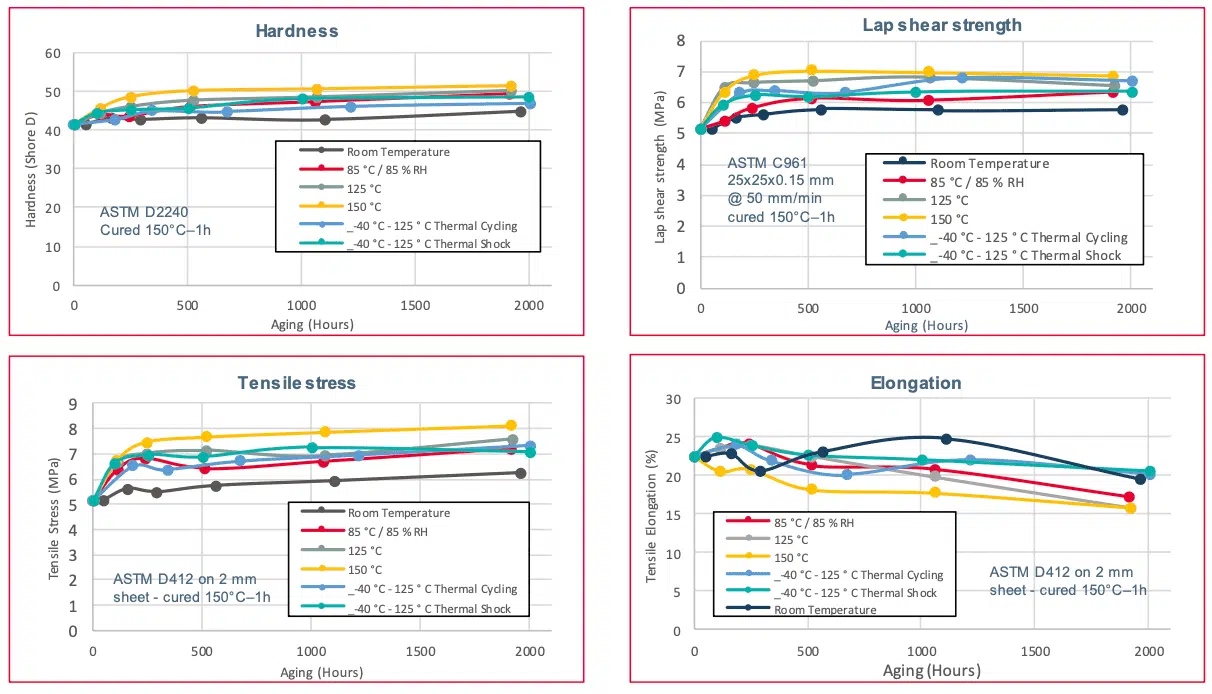

Adhesive reliability

- Stable physical properties under various ageing conditions

Shielding effectiveness – Influence of aging

- Oxidation of conductive filler influence shielding performance in sheet configuration

- Fully exposed aging (slab) does not represent real fully/partially confined configuration (FIPG) or embedded connection

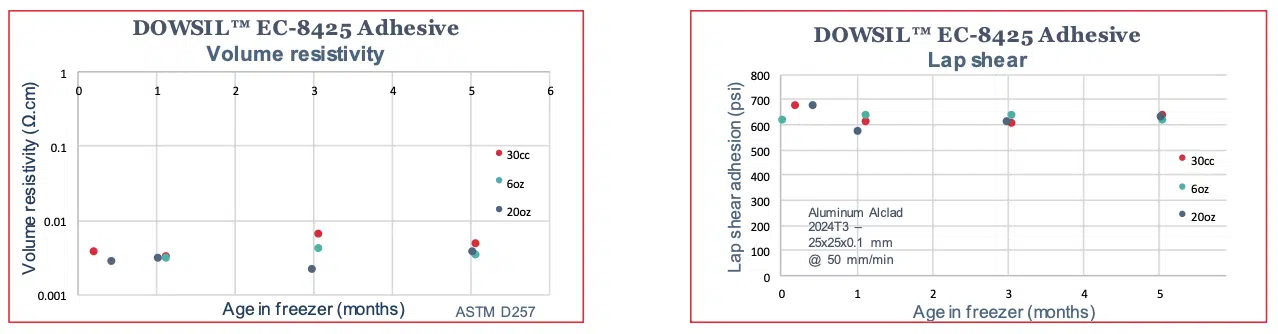

Adhesive shelf life

- Expected shelf life:minimum 6 months Freezer storage (<-10°C)

- Stable properties under freezer condition (-10°C) up to 5 months (study ongoing)

- Stable properties under refrigerated condition (+3°C) up to minimum 5 weeks

Packaging Homogeneity

- Homogeneous material vs position in the package

- No filler segregation inside the packaging

- Influence of time (settling) together with shelf life

- To eliminate risk of voids → Cartridges need to be stored vertical position tip down

- Tip up or in horizontal position may lead to plunger backward movement due to material weight

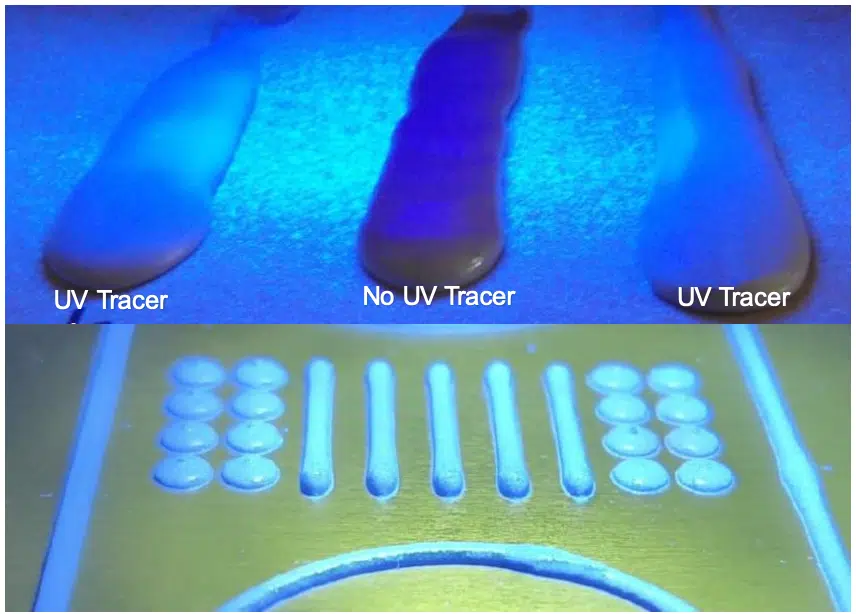

UV Indicator

365 nm Optimum inspection wavelength

For more information download here the DOWSIL™ EC-8425 Electrically Conductive Adhesive guide.