Designing the future

The market for plug-in hybrid and battery-powered electric vehicles (xEV) is on track to grow exponentially in the coming years, fueled by tumbling lithium-ion battery prices, favorable government policies, and aggressive plans from automakers to ramp up production. But realizing that potential will depend on a number of factors, including the industry’s ability to meet consumer expectations for reliability, performance, and value.

This will challenge battery makers to design for the large- volume production of lithium battery packs that are smaller, lighter, and less expensive. These higher-energy-density packs will be capable of delivering more power, longer, through better thermal control.

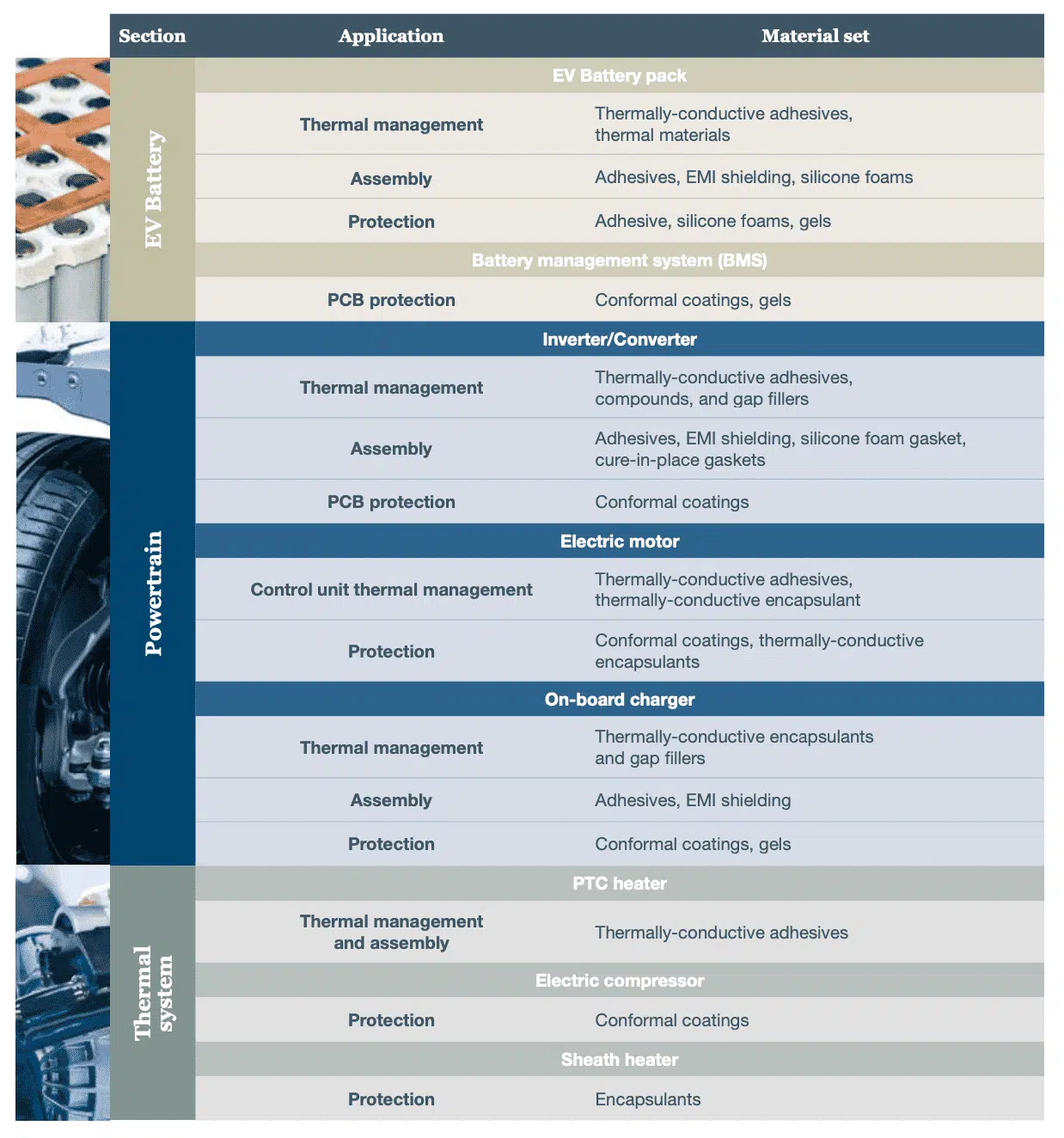

Manufacturers and designers of other xEV components – including battery management systems, power control

units, DC/DC converters, and electric motors – face many

of the same thermal management, assembly, and protection challenges. We engineer new, innovative materials to help you create new, energy-efficient products. Let’s find solutions. With excitement. With focus. With ingenuity. Together.

Silicone advantages

The silicone properties enabling Dow materials to excel in

a wide range of electronics and automotive electronics and applications could prove invaluable in addressing challenges associated with designing, and producing large volumes

of lithium battery systems and other components, for the electric vehicles of tomorrow. Some of silicone’s inherent properties addressing these challenges are:

- Very low thermal resistance

- Flow, wetting, adhesion, and cure properties that can help speed and simplify processing

- Excellent thermal stability – wide operating temperature range

- Reliable performance under harsh conditions – resistance to thermal shock, oxidation, moisture, and chemicals

- Excellent electrical insulation (dielectric strength)

- Excellent stress relief

- Silicone foams enable light weighting

Materials innovation for thermal management

Thermally-conductive silicone materials from Dow have properties that can help you reduce operating temperatures, and extend the life and performance of batteries and other electronics in electric vehicles.

• Thermal gap fillers are soft, compressible, two-part silicone, high thermal-conductivity materials specifically formulated to process easily, and to effectively dissipate heat from critical automotive parts, such as battery packs or module assemblies, and other high-heat applications.

• Thermally-conductive silicone adhesives are used for coupling the battery pack to the cooling plate.

• Non-curing, thermally-conductive silicone compounds, with a possible applied temperature range of -40°C to 150°C, are used for conducting heat in ADAS modules.

Proven solutions

Silicone adhesives, conformal coatings and encapsulants, foams, and thermal-management solutions have already demonstrated decades of proven performance under the harshest automotive conditions. They are resistant to shock, oxidation and moisture, and maintain their mechanical and chemical properties across operating temperatures from -40oC to 200oC.

• Thermal-management materials – From engineered elastomers designed for heat-resistant sealing and gasketing, to silicone gels and encapsulants for potting electronic circuitry in the battery pack’s power- management system – thermal-management materials from Dow are consistently reliable.

• Adhesives – Used in a variety of applications,

including staking large capacitors for vibration control, extra support for large components on circuit boards, electromagnetic shielding, and housing sealing, DOWSIL self-priming adhesives form long-lasting bonds without the need for mechanical fastening and clamping. In addition, many are re-workable to allow for easier module repair. They are typically solventless solutions that minimize the need for special storage, handling, or ventilation.

• Thermally-conductive silicone gels and encapsulants are flowable materials that facilitate high-volume processes in automated production, and can be used as an alternative to pre-cured pads, to provide lightweight thermal coupling between cells and modules.

• Foams – Our silicone foams are designed for efficiency in processing. The two-part, RTV foams are dispensed directly on the part surface. Foams can be a lightweight alternative to traditional encapsulant and sealant options.

• Conformal coatings – Silicone conformal coatings offer an extraordinarily broad range of durometers, as well as extremely low modulus options. That means they deliver better stress relief on delicate electronics during thermal cycling. DOWSIL conformal coatings come in a range of viscosities to help you meet all of your processing and application demands.