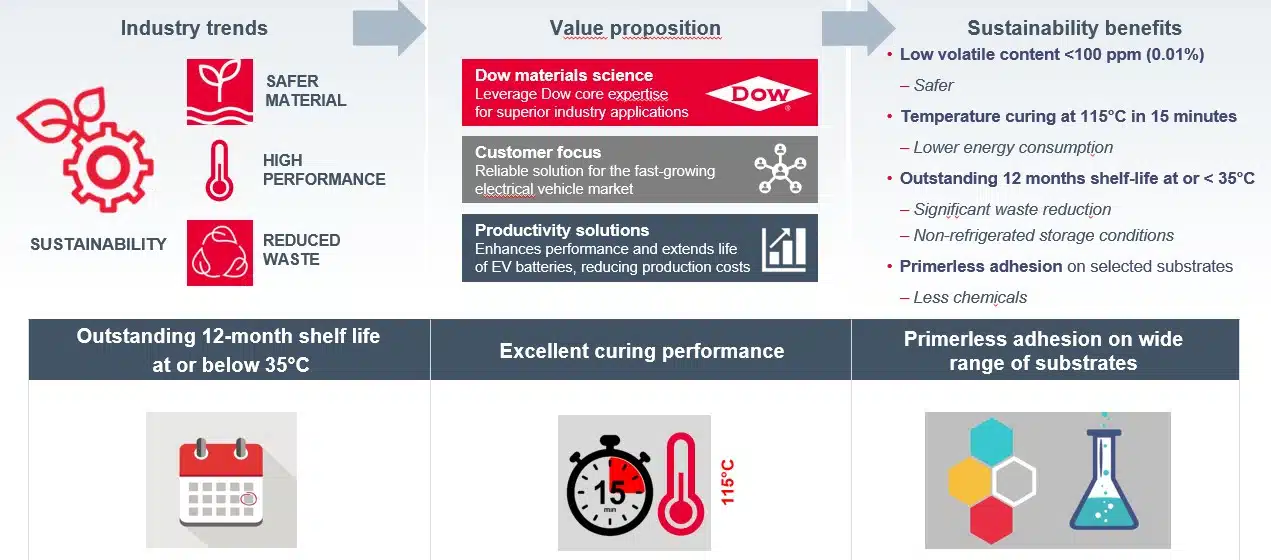

Thermally-conductive products: DOWSIL™ TC-2035 CV Adhesive

This new adhesive is a high thermally-conductive product with low temperature, fast cure and outstanding room-temperature shelf-life stability for automotive electronic assembly applications. This technology enables low-carbon mobility.

Key benefits:

- High thermal conductivity 3.3 W/m.K

- Low bond line thickness

- High elongation at break ~50%

- Easy dispensing

- Temperature curing at 115°C/15 minutes

- Primerless adhesion on selected substrates

- Long-shelf life of 12 months at or below 35°C

- Low volatile content < 100 ppm

Automotive applications:

- ADAS (Advanced Driver Assistance Systems)

- ECU Assembly

- Power electronics

- Converter/inverter

- OBC

Material properties comparison

| Property | DOWSIL™ TC-2035 CV Adhesive |

DOWSIL™ TC-2035 Adhesive |

Benefits |

| Color | Reddish brown | Reddish brown | |

| Thermal conductivity (W/mK) | 3.3 | 3.0 | High thermal conductivity |

| Specific gravity – cured | 3.00 | 03.07 | |

| Initial extrusion rate (g/min) | Part A: 33 Part B: 52 |

Part A: 43 Part B: 58 |

High dispense rate – higher throughput |

| Shelf life (months) | 12 | 6 | Lower scrap |

| Storage condition | ≤ 35°C | ≤ 25°C | Lower scrap and energy consumption |

| Pot life (hour) | 3.5 | 5 | Easier processing |

| Durometer (Shore D) | 33 | 38 | |

| Tensile strength (MPa) | 3.7 | 3.1 | Higher reliability |

| Elongation (%) | 50 | 55 | Flexible joints, less material needed |

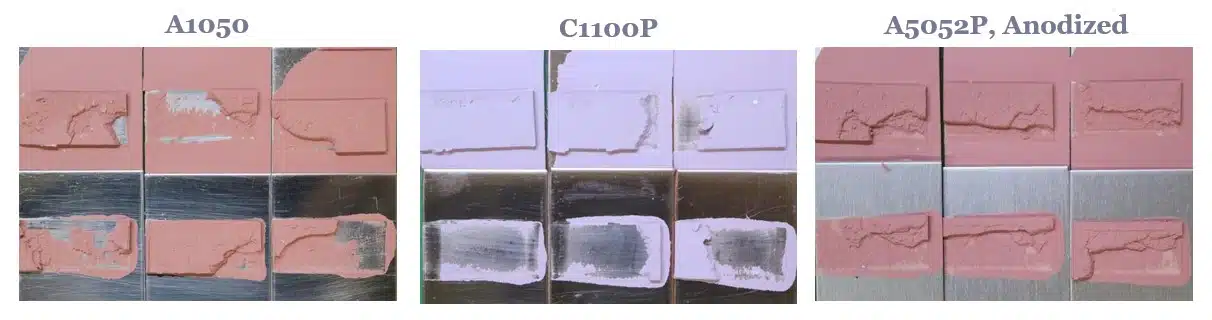

| Adhesion failure mode (%) | ≥90% Cohesive *Al – A5052P, Anodized |

≥90% Cohesive *Al – A1050P |

Good primerless adhesion |

| Lap shear adhesion (MPa) | 2.9; *Al – A5052P, Anodized | 2.6; *Al – A1050P | Stronger adhesion |

| Cure condition | 15 minutes at 115°C | 30 minutes at 125°C | Faster processing, lower energy consumption |

DOWSIL™ TC-2035 CV Adhesive

Table 1

| Test | Property |

| CTM1 0176 B | Two-part |

| CTM1 0176 B | Color: Part A – White Part B – Reddish-brown |

| CTM 0022 B | Density: Part A and Part B – 3.0 g/cm3 |

| Mix ratio – 1:1 | |

| Heat cure time at 115°C – 15 minutes | |

| Pot life at 25°C – 3.5 hours |

Table 2

| Test | Property | Result |

| CTM 0793 | Hardness, Shore D | 33 |

| CTM 1094 C | Viscosity at 1 (1/s) Part A Part B |

350 Pa.s 290 Pa.s |

| CTM 1094 N | Viscosity at 1 (1/s) mixed | 345 Pa.s |

| CTM 1393 | Minimum bond line thickness | ≤ 95 μm |

| CTM 0137 | Tensile strength | 3.7 MPa |

| CTM 0137 | Elongation | 50% |

| CTM 0243 A | Adhesion – Lap shear; Al anondized A5052P Failure mode–cohesive |

2.9 MPa ≥ 90% |

| CTM 0114 | Dielectric strength at 1 mm | 22 kV/mm |

| CTM 1163 | Thermal conductivity by transient method | 3.3 W/mK |

| DIN2 51007 | Heat capacity, volumetric at 25°C Heat capacity at 25°C |

2.63 MJ/m3K 0.88 J/gK |

| ASTM3 E 831 | Linear CTE (by TMA -50 to 200°C) | 93.6 ppm/K |

Properties of DOWSIL™ TC-2035 CV Adhesive

Thermal and electrical properties

- Thermal conductivity: 3.3 W/mK

- Dielectric strength: 22 kV/mm

- Heat capacity at 25°C: 0.88 J/gK

- Linear CTE (-50 to 200°C): 93.6 ppm/K

Primerless adhesion on select substrates

DOWSIL™ TC-2035 CV Adhesive achieves cohesive failure on most common aluminum substrates without the use of any primer.

Coefficient of Thermal Expansion (CTE)

Silicone curing mechanism

Addition-cure material

- Low cure initiation temperature with onset between 74.6 and 77.2°C and peak at 77.9 to 80.6°C

- No cure by-products

- Minimal shrinkage

![]()

Pot life and curing profile

| Pot life profile | |||||

| Initial | 120 minutes |

180 minutes |

210 minutes |

240 minutes | |

| 1 (1/s) Pa-s |

323 | 372 | 460 | 566 | 741 |

| Viscosity change | 15% | 42% | 75% | 130% | |

Stable viscosity

- Viscosity of DOWSIL™ TC-2035 CV Adhesive remains completely stable throughout its shelf life

- Almost non-existent sedimentation or separation

High purity material

| Total D4-D6 content below 100 ppm | |||

| (Unit: µg/g) | D4 | D5 | D6 |

| Batch 1 | 18.90 | 5.40 | 2.40 |

| Batch 2 | 20.20 | 5.50 | 2.50 |

| Average | 19.50 | 5.45 | 2.45 |

| Ionic species below 5 ppm | |||

| Element | DOWSIL™ TC-2035 CV Adhesive (1) |

DOWSIL™ TC-2035 CV Adhesive (2) |

DOWSIL™ TC-2035 CV Adhesive (3) |

| Cation measurement results | |||

| Sodium | <2.64 | <2.64 | <2.64 |

| Potassium | <1.13 | <1.13 | <1.13 |

| Anion measurement results | |||

| Fluorine | <0.32 | <0.32 | <0.32 |

| Chlorine | <3.33 | <3.33 | <3.33 |

| Bromine | <0.58 | <0.58 | <0.58 |

Processing

- Minimum BLT ≤ 95 µm

- Mixing ratio 1:1

- Cure profile 15 minutes at 115°C

- Pot life 3 to 4 hours at 25°C

- Fast dispensing

- Extrusion rate Part A: 33 g/min

- Extrusion rate Part B: 52 g/min

Mixing ratio tolerence

| Properties | Range | Initial mixing ratio A/B=100/100 |

Initial mixing ratio A/B=115/100 |

Initial mixing ratio A/B=100/115 |

|

Viscosity of mixture

|

1700 ± 500 Pa·s | 1734 | 1629 | 1555 |

| 330 Pa·s ± 150 Pa·s | 348 | 338 | 332 | |

| 150 +- 40 Pa·s | 152 | 151 | 150 | |

| Change of viscosity (2 hr) | under 20% increase | 3 | 7 | 3 |

| Thermal conductivity | 3.4 W/mK +/- 0.3 W/mK | 3.4 | 3.3 | 3.3 |

| Tensile strength | 2.9 MPa -0.7/+ 1.5 MPa | 3.6 | 3.1 | 3.8 |

| Tensile properties elongation at break |

55% – 10 /+ 25% | 47 | 56 | 49 |

| Linear strain limit | 5% +- 0.5% | 5.2 | 5.0 | 5.0 |

| Curing parameters | ||||

| Specific density | 3.00 +/- 0.1 g/cm³ | 2.99 | 2.99 | 2.99 |

| Shore hardness | 28 +/- 10 Shore D | 38 | 33 | 37 |

| Tensile lap shear strength | A5052P 2.3 N/mm² – 0.5 /+ 0.9 N/mm² |

03.04 | 2.56 | 3.15 |

Overview DOWSIL™ TC-2035 CV Adhesive