MOLYKOTE® G-8101 Grease is a perfluoropolyether (PFPE)- based grease thickened with polytetrafluoroethylene (PTFE); it is useful for reducing wear in many plastic-on-plastic applications.

Applications

MOLYKOTE® G- 8101 Grease can be used broadly under harsh conditions, such as high temperatures, corrosive, solvents, liquefied natural gasses, high vacuum, etc. Can be used in cleanroom equipment and semiconductor manufacturing equipment where the vaporization of the lubricating material is undesirable.

Features & benefits

- Compatible with most plastics

- Excellent stability at high temperatures

- Superior resistance to chemicals and solvents

- Minimal deterioration due to oxidation; appropriate forlong- term lubrication

- Low vapor pressure (base oil)

Composition

- Perfluoropolyether

- Fluorinated polymer

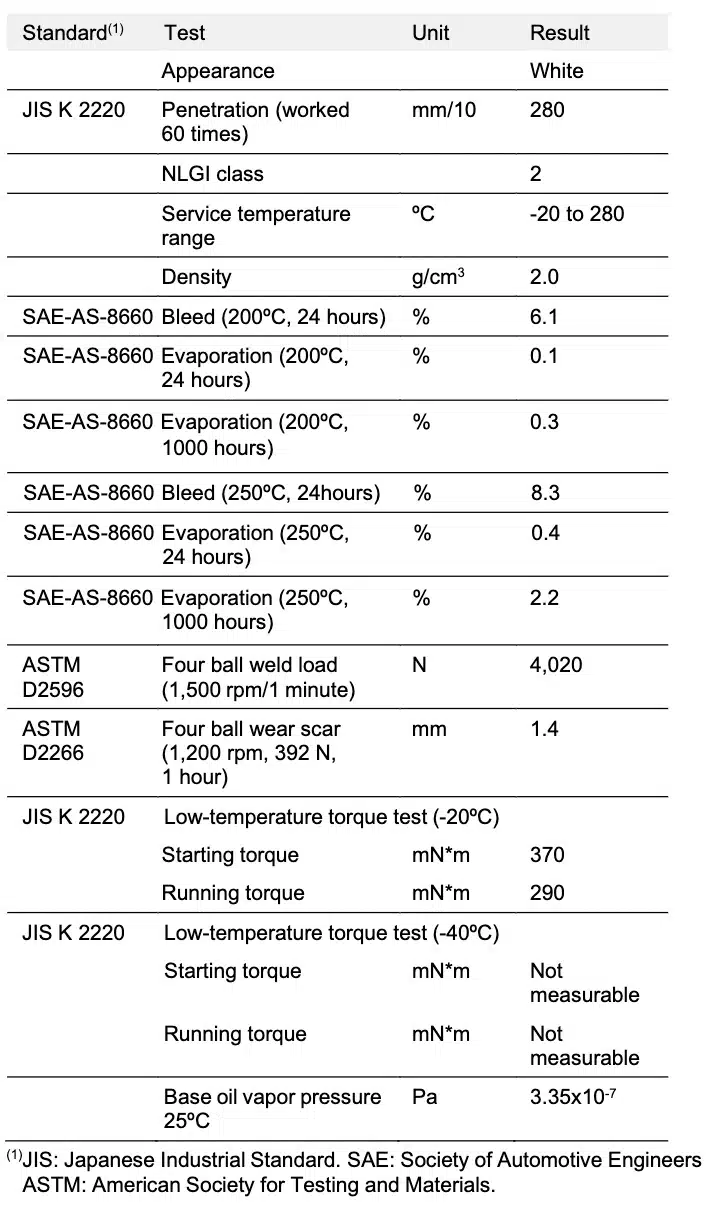

Typical properties

* Specification writers: These values are not intended for use in preparing specifications. Please contact your local MOLYKOTE® sales representative prior to writing specifications on this product.

Potential Applications

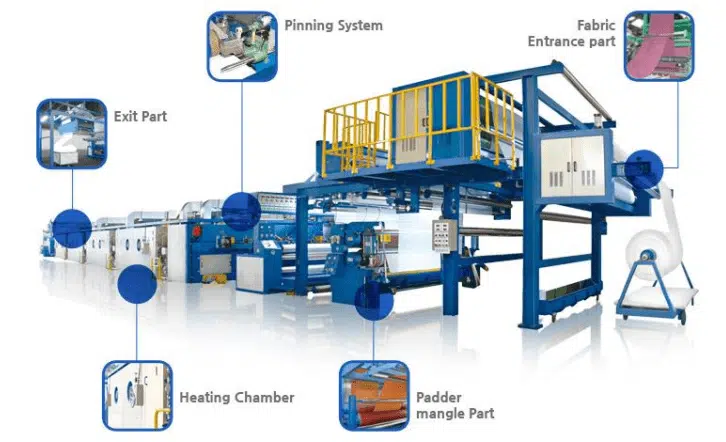

- High temperature bearing of textile stenter chains, drying cylinder; auto painting line; corrugated roll bearings in corrugators.

- Mold metal moving parts (guide pin, ejector pin, slider part) for high temperature. Engineering plastic (PEI, PAI, PTFE, PSF, PPSU…).

- MRO application in Q&G segment for valve sealing and bearings in corrosive, solvents conditions (due to high viscosity).