MOLYKOTE® P-1042 Adhesive Grease Paste

High load-carrying capability with greater washout resistance for enhanced productivity. An outstanding resistance to washout by water and metal-machining emulsions.

MOLYKOTE® P-1042 Adhesive Grease Paste was initially developed for industrial lathe chucks, which require constant clamping force in harsh environments.

Because as manufacturers use more aggressive cooling fluids in metal machinery and clamping mechanisms – such as lathe chucks – highly washout-resistant lubricants with reliable tribological performance are a requirement to reduce downtime and minimize relubrication cycles. MOLYKOTE® P-1042 Adhesive Grease Paste is a light-colored grease-paste fortified with solid lubricants, designed for sliding surfaces exposed to high-pressure loadings and subjected to the influence of water or metal-machining emulsions. With a patented formula specifically designed to properly lubricate clamping mechanisms, MOLYKOTE® P-1042 Paste enables manufacturers to deliver consistent clamping force on lathe chucks. Additionally, MOLYKOTE® P-1042 Paste does not experience hardening issues during service.

A direct response to market needs and trends

Extended durability and maintenance schedules deliver productivity. Lubricants must retain their lubricating performance under greater production and environmental stresses.

MOLYKOTE® P-1042 Adhesive Grease Paste:

- Has a patented formula specifically designed to:

- Provide superior high load-carrying capability

- Properly lubricate clamping mechanisms

- Exhibits superior tackiness on metal and metallic surfaces for longer-term performance

- Offers resistance to washout by water and steam – designed to tolerate humid environments while under high temperatures

- Does not experience hardening issues during service

Balanced for clamping tools

The use of more aggressive cooling fluids in metal machinery requires the use of lubricants that are highly resistant to those fluids while retaining tribological performance.

MOLYKOTE® P-1042 Adhesive Grease Paste:

- Has a patented formula specifically designed to properly lubricate clamping mechanisms such as lathe chucks

- Offers resistance to washout by water and by modern cooling fluids applied on the tool, providing a constant level of desired clamping force

- Enables manufacturers of lathe chucks to supply a clamping unit with constant performance in terms of desired clamping force, reduced downtime and lower relubrication cycles

- Does not experience hardening issues during service

Additional potential in harsh metal/metal applications

MOLYKOTE® P-1042 Adhesive Grease Paste offers:

- High load-carrying capacity

- Superior tackiness for excellent adhesion to metallic surfaces

- Outstanding resistance to washout by water and metalmachining emulsions

- High-temperature resistance

- Tribo-corrosion avoidance

- Stick-slip prevention

- Excellent protection against galling

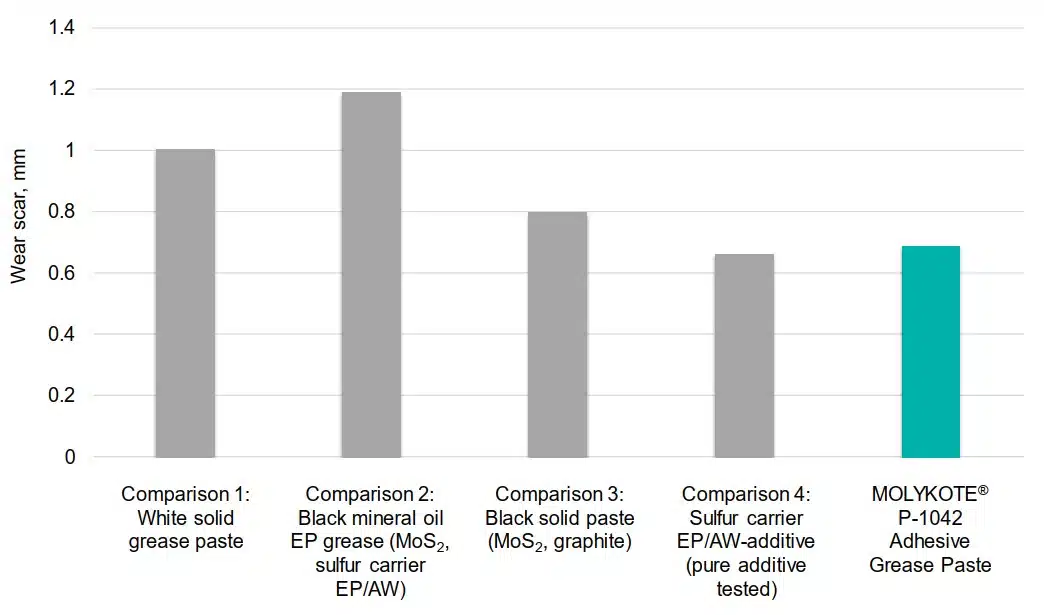

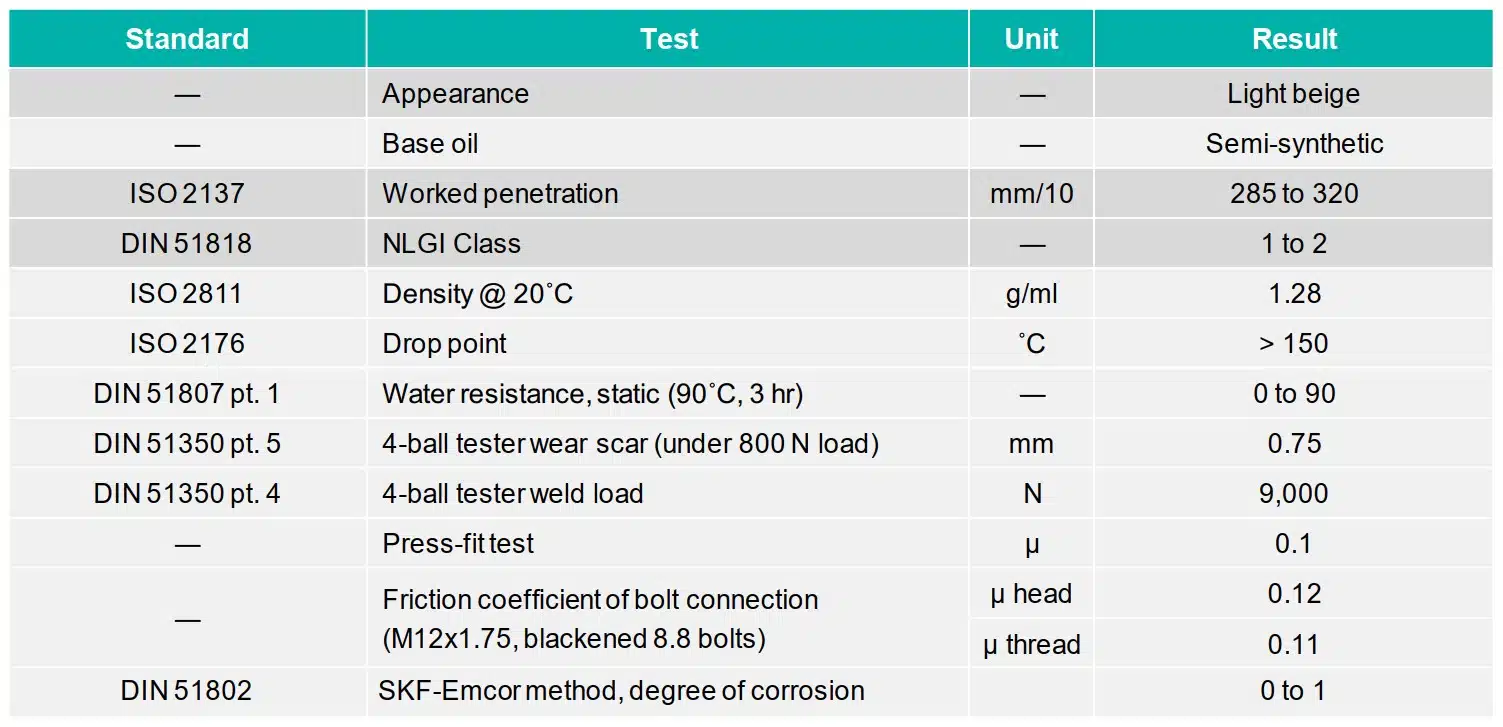

Load-carrying capacity

- 4-ball test machine

- DIN 51350 pt. 4

Anti-wear performance

- 4-ball test machine

- DIN 51350 pt. 5

- 1 hr @ 800 N

Corrosion protection and water resistance

Emcor corrosion protection test

DIN 51802, 7 days, distilled water

Rating: 0 (no corrosion)

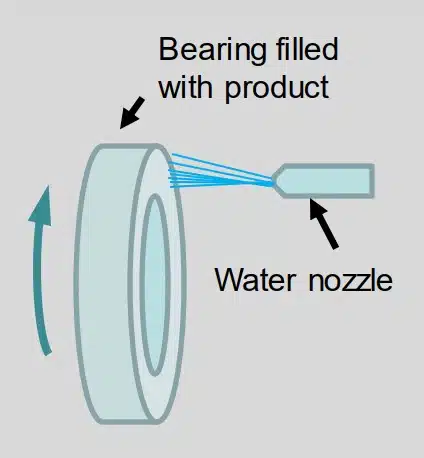

Water washout test

ASTM D1264,

1 hr @ 80°C

< 5 wt%

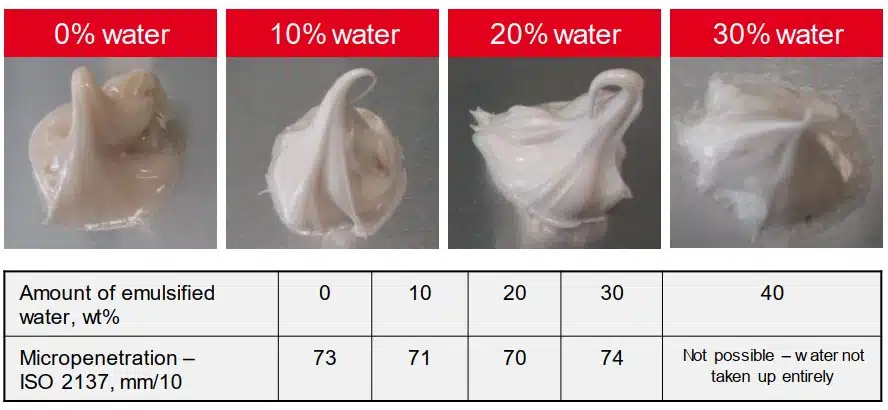

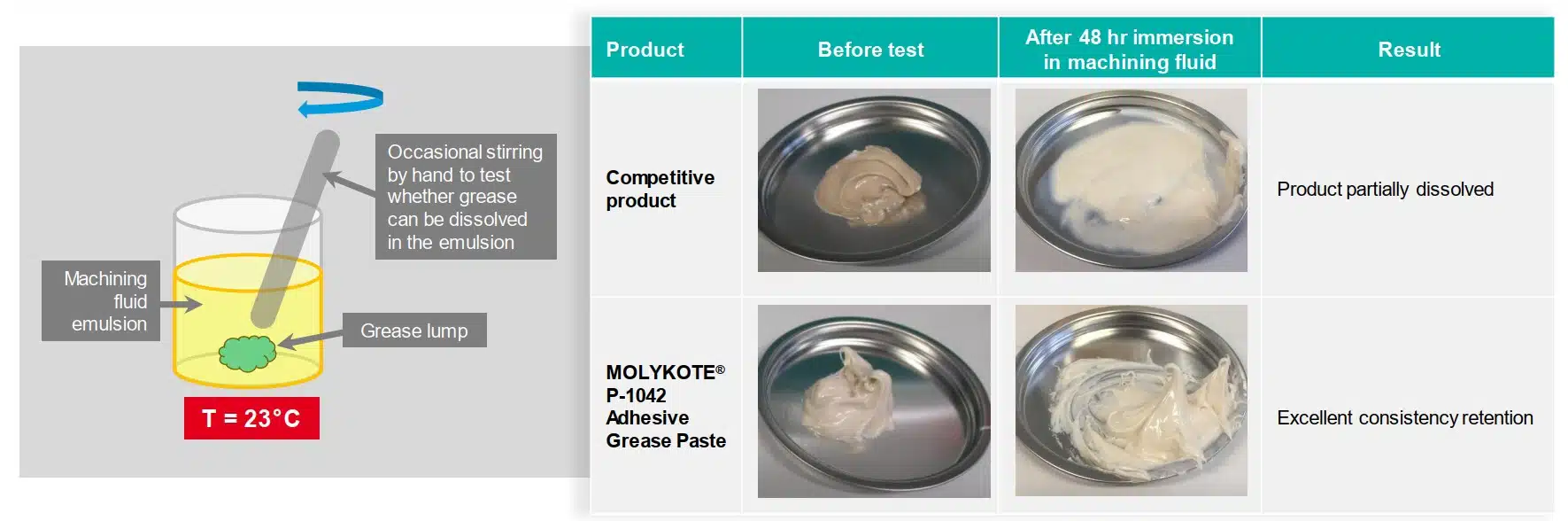

Water emulsion test

Able to absorb up to 30 wt% of water without loss of consistency

Static machining fluid compatibility test

Grease submerged in machining fluid emulsion at 23°C and occasionally stirred by hand to test whether it can be dissolved in the emulsion.

Technical data

Summary

Key features

- High load-carrying capacity

- Strong adhesion to metal surfaces

- Outstanding resistance to washout by water and by metal-machining emulsions

- Avoids tribo-corrosion

- Excellent protection against galling

Benefits to customers

- In clamping tools: Provides desired, sustained level of clamping force with reduced downtime and relubrication cycles

- In metal-to-metal applications under high load: Provides extended durability, including in hot, humid or wet environments