Proper tightening and corrosion prevention help to avoid bolt failure on wind turbines.

Help improve assembly quality, safety and reliability with proper tightening. Prevent corrosion, avoid bolt failure and reduce service costs. Use Molykote® brand Smart Lubrication™ solutions for

strong threaded connections on:

- Nacelle frame joints

- Front and rear main journal bearings

- Pitch bearing fasten bolts

- Gearbox, drives and cooler units

- Yaw bearing fasten bolts

- Tower segment flange bolts

- Foundation anchor bolts

Safe, reliable wind turbines depend on strong threaded connections

Frequent problems with threaded connections:

- Tightening difficulties and thread damage

- Inconsistent or loose clamping force

- Broken bolts and base parts, such as flanges or plates

- Difficult disassembly and destroyed threads

Good lubricants for bolts and fasteners can help solve problems and increase reliability by reducing the effects of root causes, including:

- Seizure and abrasive wear

- Uneven coefficient of friction

- Fretting corrosion

- Embrittlement failures of substrates due to use of low-melting-point metals, such as lead, tin and copper

- Stress corrosion cracking

Good lubrication can help reduce torque resistance, prevent damage and improve clamping force on thousands of differentsized threaded connections on wind turbines.

Investigate our solutions for threaded connections

Molykote® 1000 and Molykote® G-Rapid Plus pastes

Tighten all assembly bolts to required tension with correct torque: Thread roughness creates uneven friction and incorrect bolt tightening during installation. Lubricate threads with Molykote brand pastes to achieve a low and consistent coefficient of friction, thus helping to ensure proper tightening and tension on all wind turbine assembly bolts.

Protect threaded connections for longer service life: Bolts and fasteners on equipment joints must stay invulnerable in heat, cold, pollution, rain, snow and even salt fog. Apply Molykote brand pastes to help provide threaded bolts with increased, long-lasting protection from corrosion and seizure.

Help to allow easier disassembly of threaded connections: Corrosion, adhesion and seizure make disassembly difficult after long outdoor service. Use Molykote brand pastes for bolt lubrication, protection from fretting corrosion and easy disassembly without damage.

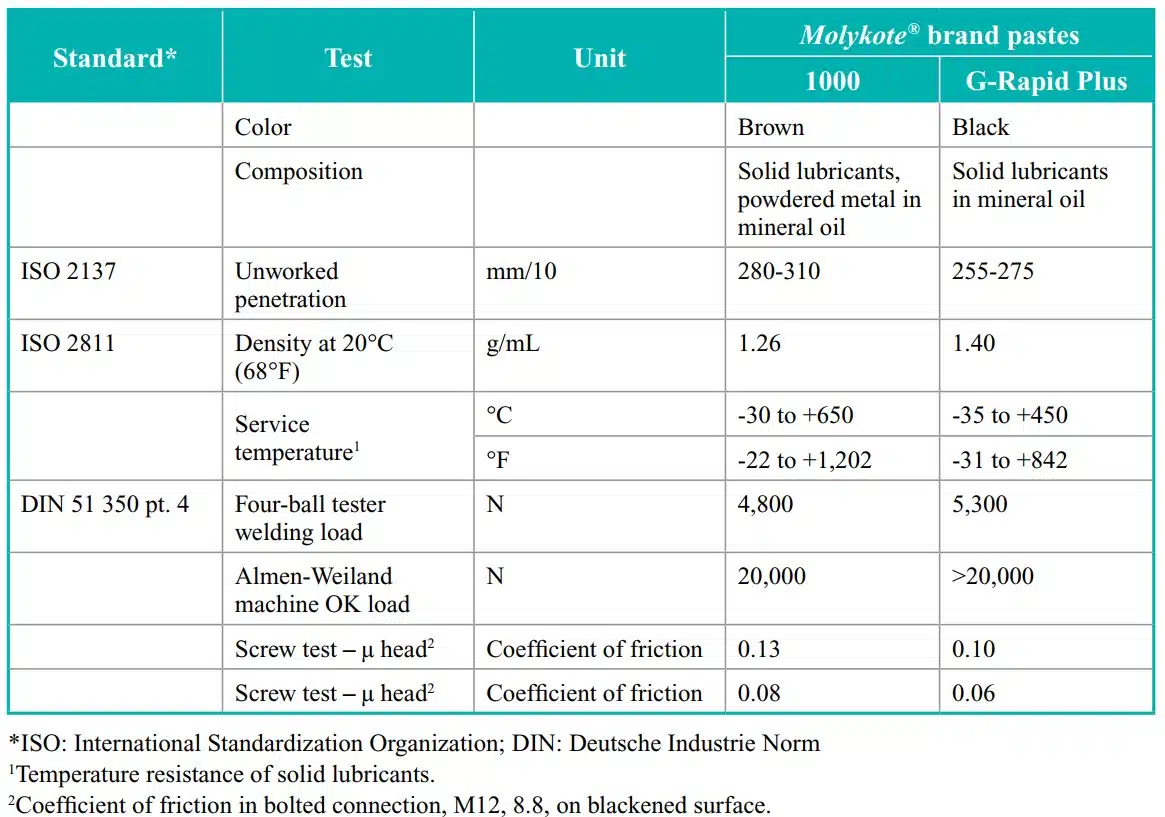

Typical Properties

Proper Lubricant Use

Molykote 1000 and Molykote G-Rapid Plus pastes are easy to use:

- Clean the thread and bolt with a brush, if needed.

- Stir the paste before applying.

- Spread an adequate amount of paste on the thread and up to its root to obtain a good seal. Cover all surfaces, including washers, without waste.

- Do not mix with other greases or oils; this can alter the paste’s properties.

Product Packaging

Molykote 1000 and Molykote G-Rapid Plus pastes are available in different standard container sizes. Contact us for details.