Encapsulants and Gels Selection Guide

Minimizing Stress to Maximize Reliability with Proven Silicone Encapsulants and Gels

Why Choose a Silicone Encapsulant or Gel versus a Conformal Coating?

Encapsulants offer better protection and faster, simpler cure options than coatings when:

- PCB features and components are taller than 200 microns

- A PCB presents a more complicated landscape, or thin sensitive wires or solder joints

![]()

Why Choose Silicones versus Organic-Based Encapsulants and Gels?

As a class of materials, silicones generally offer demonstrable benefits over urethane and epoxy solutions, including:

- Maximum protection – especially from silicone gels – against mechanical stress caused by thermal cycling or mismatched coefficient of thermal expansion

- Extraordinary protection against shock and vibration

- Superior thermal stability for more reliable performance at sustained temperatures between -45°C and 200°C

- Greater hydro-stability and stronger resistance to chemicals and UV radiation

- Reduce or eliminate special precautions related to typical safe-handling of organics

- Cure schedule variation of silicones impose a significantly lower impact on end properties

- Simpler processing without the need for oven drying or concerns about exotherms

- Ease of repair when module rework is necessary

- A wide selection range of special features, targeting multiple functions like thermal management, improved processing efficiency and others

What’s Best for Your Application, an Encapsulant or a Gel?

DOWSIL™ encapsulants and gels offer many of the same benefits, including excellent dielectric protection, strong seals against environmental contaminants, and excellent thermal stability and stress relief ranging from good to outstanding. Yet each material class offers distinguishing advantages.

Easy Processing

Most encapsulants and gels in our portfolio are two-part addition cure silicones that, as a class of materials, offer several processing advantages over organic materials. Silicones can help to reduce or eliminate special handling precautions required for organics related to their toxicity. Unlike urethanes, they do not require the costly use of ovens to thoroughly dry components before processing. Unlike epoxies, silicones impose no concerns about exotherms.

Dow Performance Silicones’ portfolio of encapsulants and gels offers a wide variety of viscosities before cure, allowing either shorter cycle times or longer, more controlled flow according to your needs. Our broad selection also offers flexible options for simple, roomtemperature cure or accelerated heat curing for enhanced productivity.

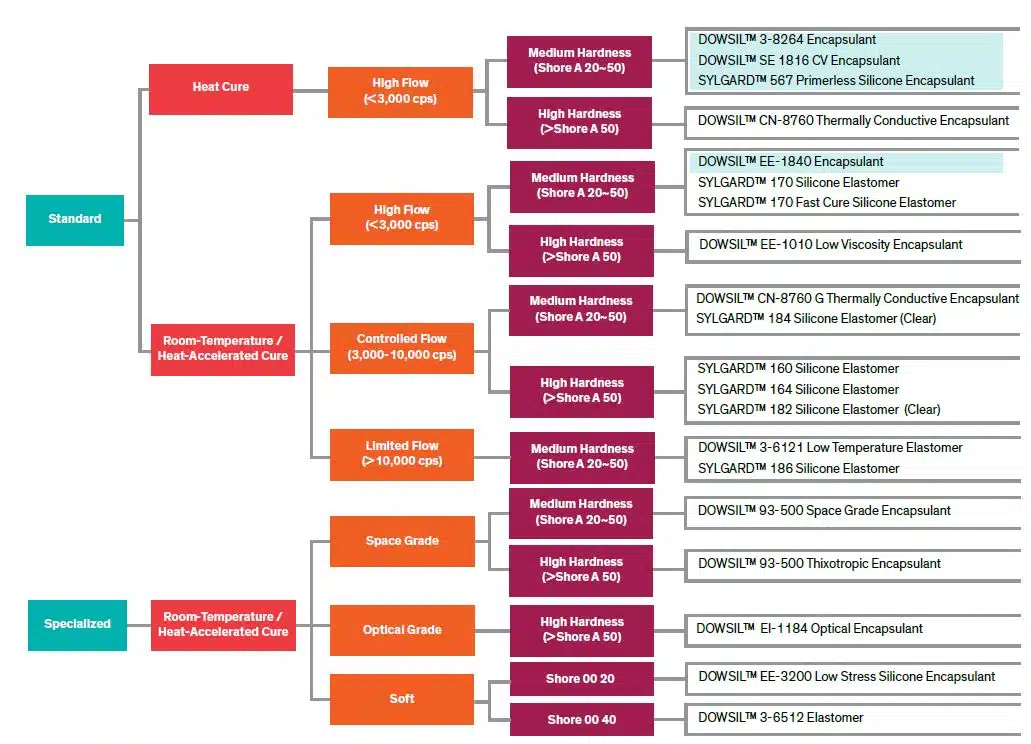

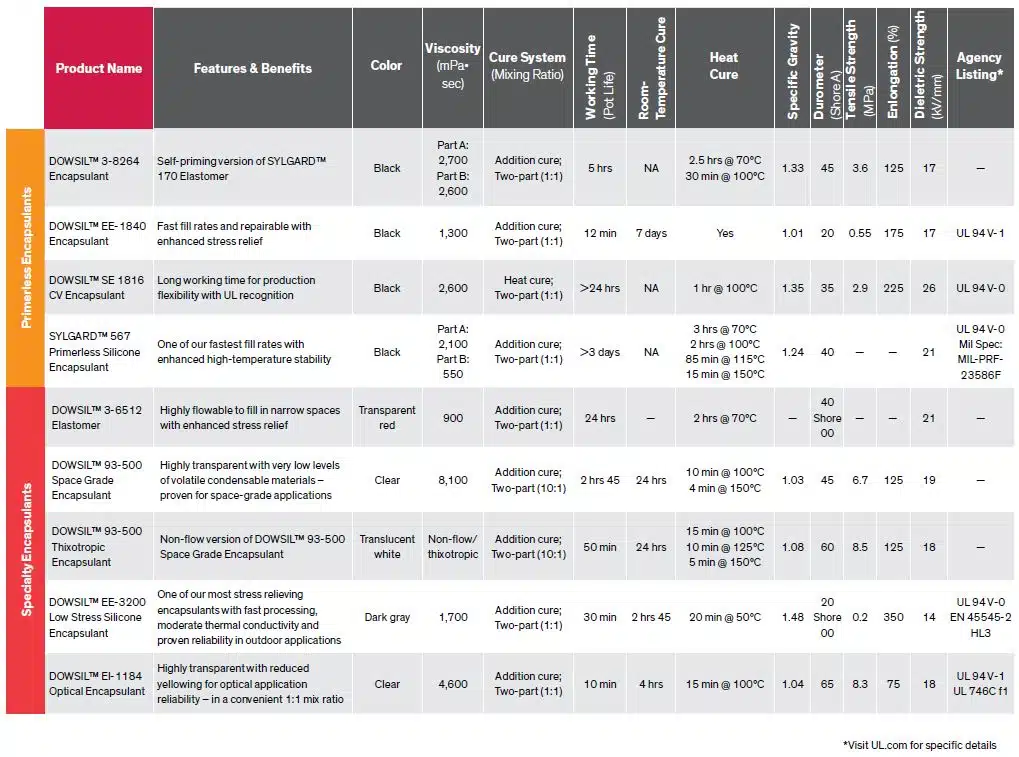

Choosing an Encapsulant

Encapsulants from Dow Performance Silicones generally fall into three categories: standard, primerless self-adhering, and specialty grades. Standard encapsulants require a priming step if strong adhesion is needed for extra protection. In contrast, self-priming encapsulants adhere to many common surfaces when heated to temperatures above 100°C during the cure process. With hardness ranging from Shore 00 20 to Shore A 65, encapsulants from either category offer a versatile selection of proven solutions for any application. Our specialty grades offer unique properties and benefits, such as thermal conductivity, high transparency, or compliance with military specifications.

This product selection tree will help you quickly narrow your search for an optimal encapsulant for your application. Further details and properties of each product can be found in the product table starting.

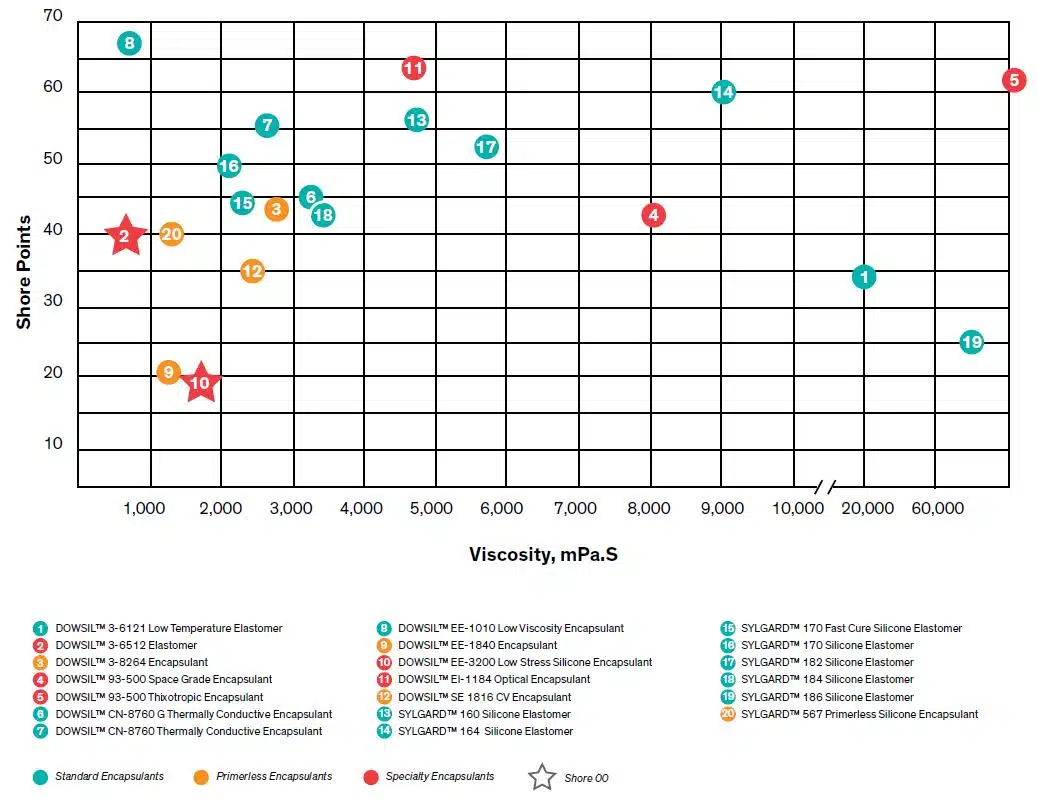

Encapsulants Viscosity/Hardness

Standard Encapsulants

Primerless and Specialty Encapsulants

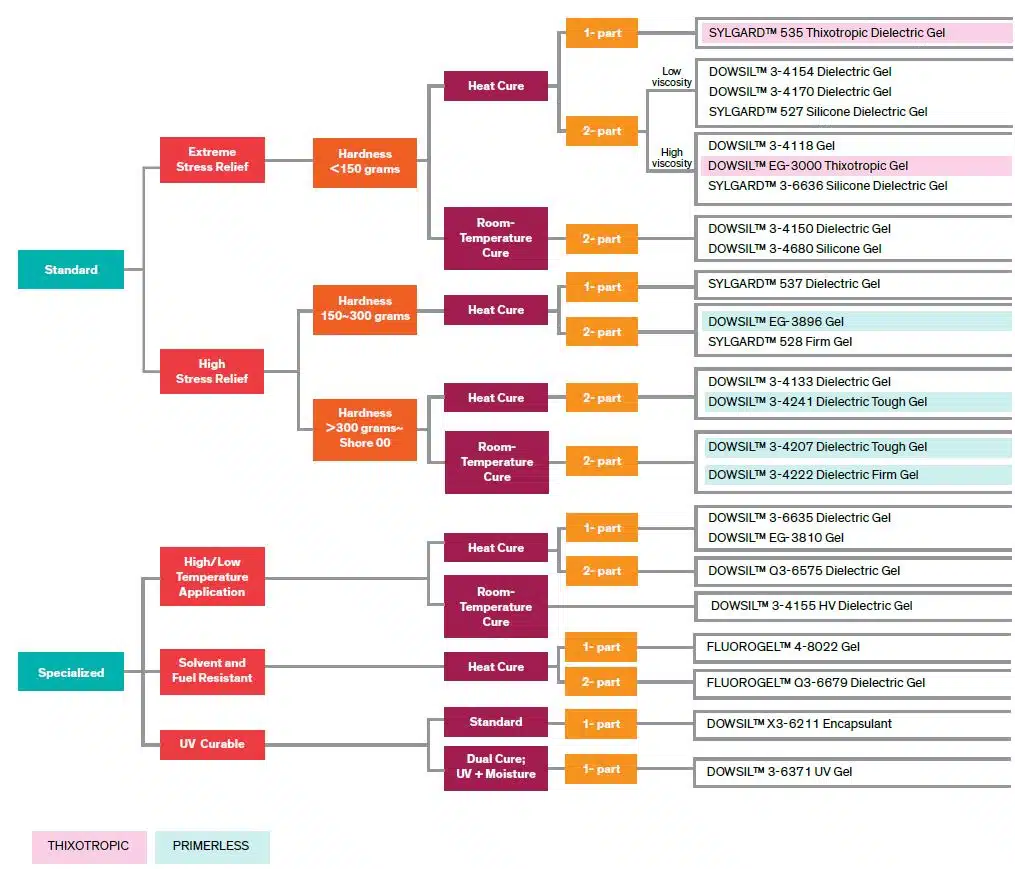

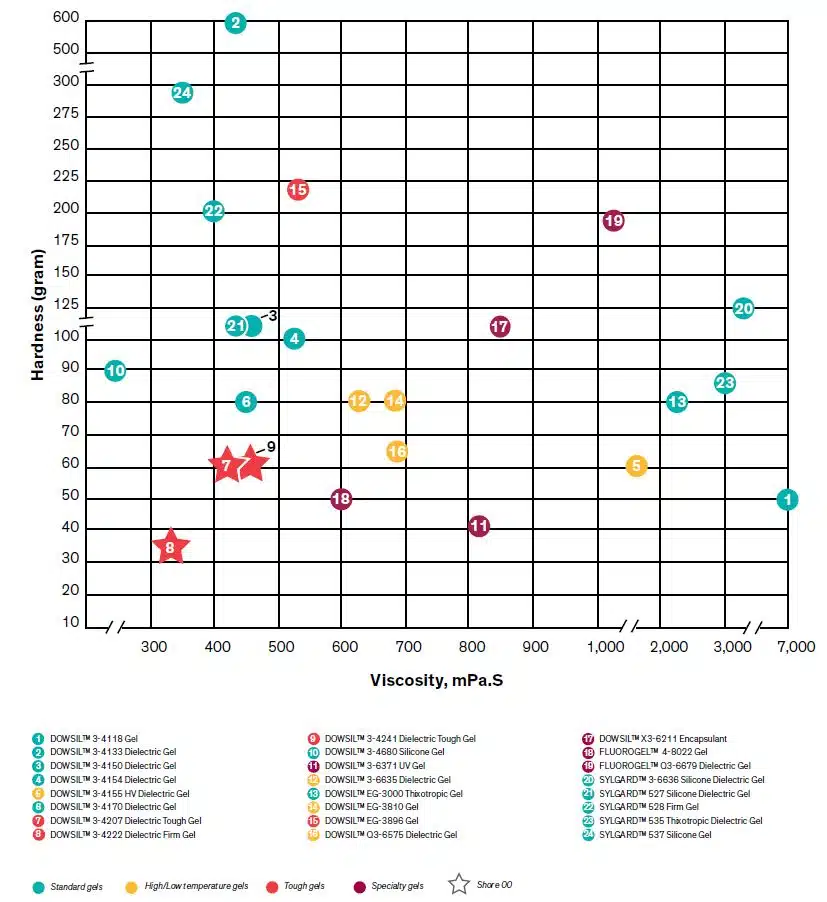

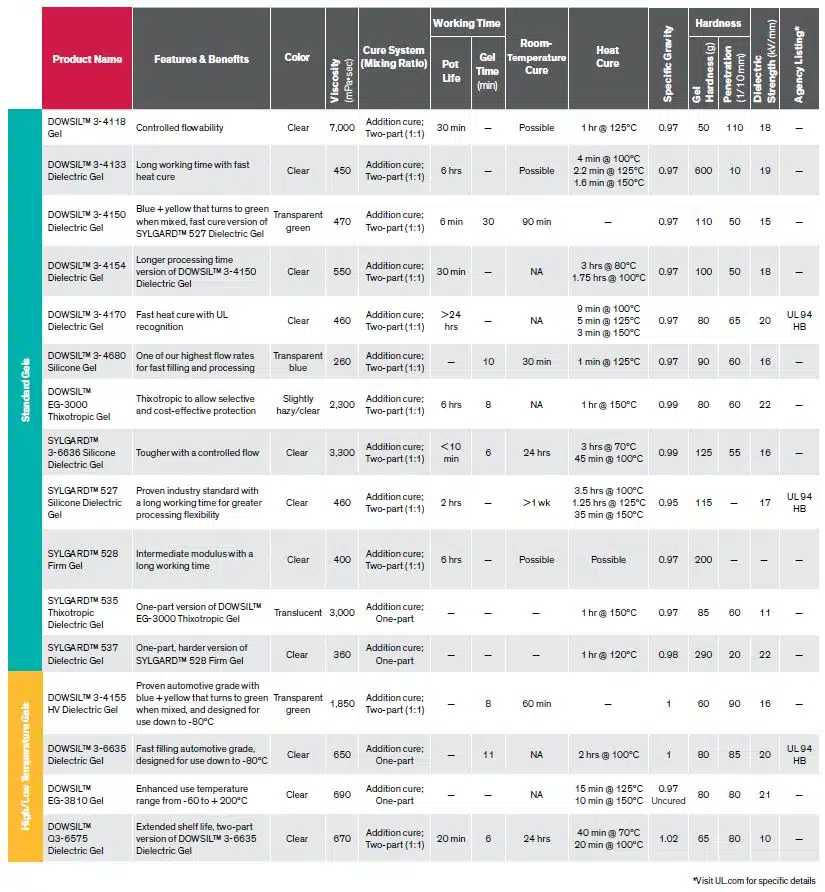

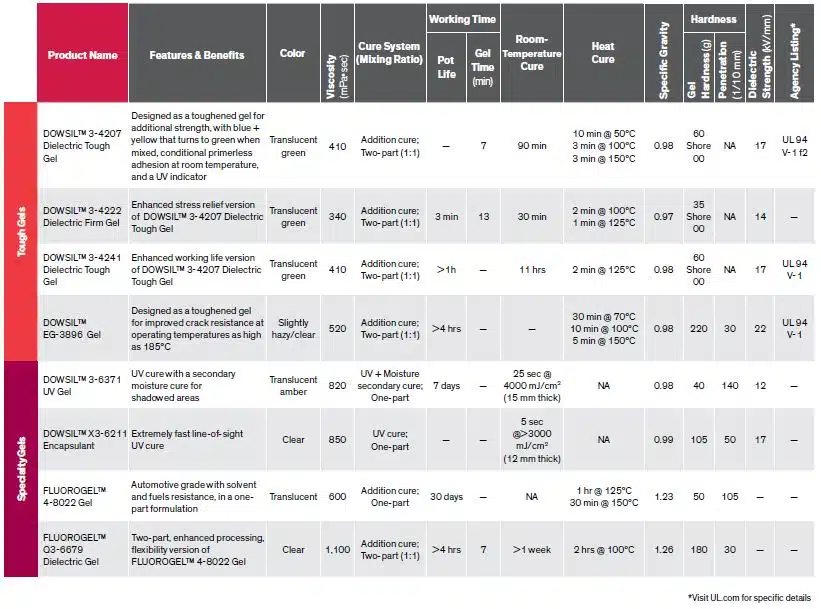

Choosing a Gel

Offering the ultimate in stress relief, most gels also exhibit a tacky surface that adheres naturally to common surfaces, without the need for primers. Dow Performance Silicones’ broad selection of gels are organized into four families: standard, low-temperature, toughened, and specialty. Product specification is typically determined by the application’s need for stress relief, viscosity, or cure

time versus working time.

This product selection tree will help you quickly narrow your search for an optimal gel for your application. Further details and properties of each product can be found in the product table.

Gels Viscosity/Hardness

Standard and High/Low Temperature Gels

Tough and Specialty Gels

Learn More

We bring more than just an industry-leading portfolio of advanced silicone-based materials. As your dedicated innovation leader, we bring proven process and application expertise, a network of technical experts, a reliable global supply base, and world-class customer service. Contact Us

![]()