Krytox™ Technology Improves Steam Turbine Governor Control and Reliability

The Problem

Turbine cam shaft or valve lift bar anti-friction bearings, bushings, and gears using conventional lubricants wear, fail, or lock up over time. This causes excessive clearance, rough response, and potential seizing of the governor control, resulting in:

Operational Issues

- Turbine downtime

- Loss of steam feed control

Maintenance Issues

- Increased maintenance effort and cost

- Frequent re-lubrication

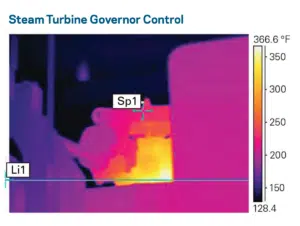

- Employee exposure to extreme component temperatures

- Failed bearings

- Oxidation of the conventional lubricant

- Increased turnaround time to clean, break down, and replace components

The Solution: Lubricants for Steam Turbine.

Krytox™ lubrication technology for turbine governors has been demonstrated to provide the best available equipment performance and lowest available life cycle cost. Krytox™ grease will not oxidize or break down. The benefits include:

Operational Benefits

- Improved turbine uptime

- Improved turbine control

- Reduced operating expense

Maintenance Benefits

- Extended component life

- Extended re-lubrication interval

- Safer work environment

- Reduced effort and cost

Chemours Benefits

- Demonstrated in field use for over 7 years

- Ongoing support to deliver performance and savings

- Krytox™ grease is formulated to lubricate and protect turbine governor cams, anti-friction bearings, bushings, linkages, and gears

- Krytox™ grease takes the heat without breaking down

- Krytox™ grease protects components from vibration and fretting wear

OEM Specifications

Krytox™ lubricant is specified for use by Siemens Westinghouse for mechanical components requiring lubrication in high temperature environments on steam turbine, gas turbine, and generator systems. Refer to Siemens Specifications M-Spec 53701Y6, M-Spec 537001TT, and M-Spec 53701VH.

Demonstrated Solutions

For over 20 years, Krytox™ lubrication technology has provided state-ofthe-art performance for mechanical systems under harsh conditions. From gearboxes, bearings, and chains—to seals, actuators, valves, and more—Krytox™ lubricants serve the specialized needs of:

- Pulp and paper mills, and converting plants

- Automotive components

- Military and commercial aircraft

- Chemical plants

- Power plants

- Turbine generators and other critical industrial applications.

And that is all the needed information about the new Lubricants for Steam Turbine If you have any doubt, you always can contact us and we will help you.