High-temperature resistance and microsealing property; optimized for coil coating

Responding to market needs and trends toward reduced emissions

As emission standards become more stringent, manufacturers face tough lubrication challenges. MOLYKOTE®D-6900 Anti-Friction Coating provides excellent lubrication and high-temperature resistance, and it delivers a micro sealing property.

In addition,MOLYKOTE®D-6900 Coating can be coil-coated at a desired film thickness of 16-20 µm,allowing OEMs to produce metal gaskets, such as exhaust manifold gaskets (EMGs) that can help them achieve emission reduction targets and meet EURO 6 specifications.

Excellent heat resistance

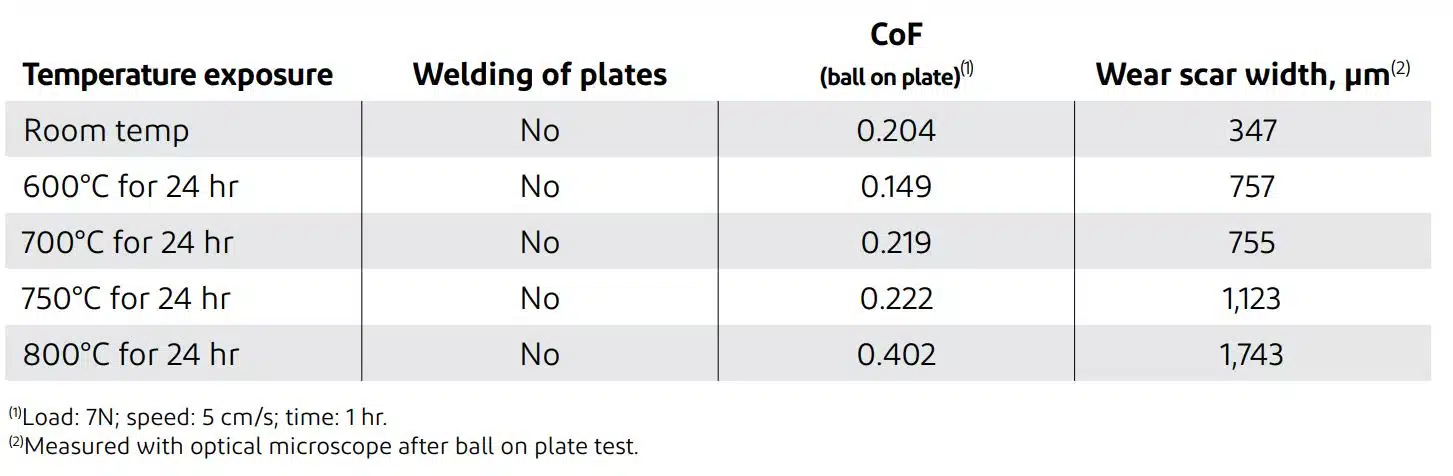

Ball on plate test: Similar wear scar widths at 600°C and 700°C indicate resistance of MOLYKOTE® D-6900 AFC up to 700°C in the absence of oxygen

Good acid and coolant resistance

Meet emission specifications MOLYKOTE®D-6900 Anti-Friction Coating offers:

- Micro Sealing property

- High-temperature welding prevention

- Excellent heat resistance

- Good acid and coolant resistance

Globally available, MOLYKOTE®D-6900 Anti-Friction Coating – an NMP/NEP-free AFC – is optimized for coil coating. Exhaust manifold gaskets coated with MOLYKOTE®D-6900 Coating fulfill EURO 6 emission specifications, even at 600°C. Laboratory tests indicate full functionality up to 700°C, as shown in the table at right.

MOLYKOTE®D-6900 Coating prevents welding of metal/metal combinations at high temperatures and can be used in sliding contact of metal/metal combinations with slow to moderately fast movements and high loads.

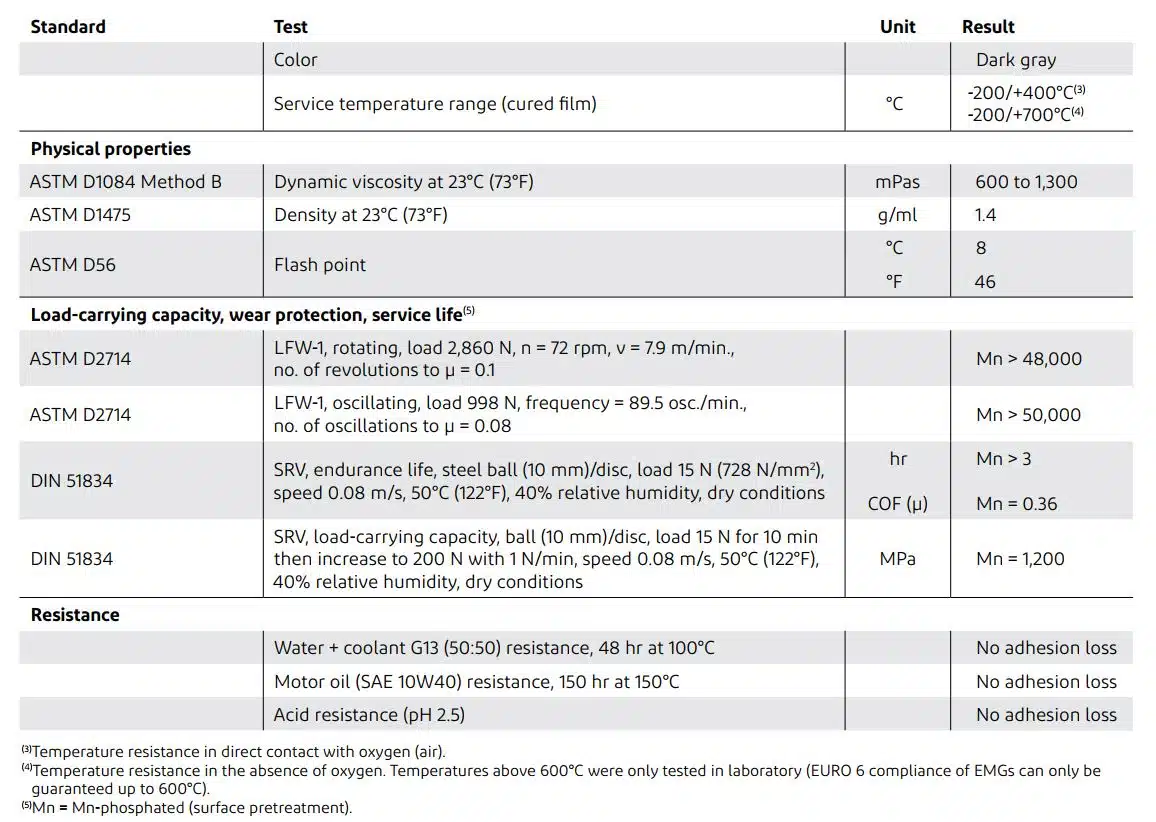

Typical properties

Features

- Excellent lubrication

- Good acid resistance

- Good solvent resistance

- High load-carrying capacity

- Excellent adhesion to metal

- Low coefficient of friction

- High resistance to motor oil and coolant

- Excellent heat resistance

- Suitable for coil coating

- NEP/NMP-free

Composition

- Solid lubricants

- Organic binders

- Organic solvents

Applications

- Metal gaskets with high-temperature-resistance property(e.g.,exhaust manifold gaskets). Coating offers micro sealing property(fulfilling EURO 6 emission specifications up to 600°C)and prevents welding of metal/metal combinations at high temperatures. (NOTE: Temperatures above 600°C have not yet been tested.)

- Sliding contact of metal/metal combinations with slow tomoderately fast movements and high loads.

How to use

Surface preparation

First,thoroughly clean and degrease the surface that will be coated with MOLYKOTE®D-6900 Anti-Friction Coating.Phosphating or sandblasting (100/180 grit–80/130 μm)increases the adhesion and service life.

How to apply

Stir MOLYKOTE®D-6900 Anti-Friction Coating thoroughly before applying by coil coating or screen printing. Recommended dry film thickness: 10to 20 µm (mean value).

Curing

Recommended curing conditions: 30 minutes at 200°C (392°F).However,curingtimedependssubstrate material, size, mass,coating thickness and type of curing system.

Dilution

Viscosity of MOLYKOTE®D-6900 Anti-Friction Coating can be decreased with MOLYKOTE® L-13 Thinner.

Coverage

1Kg of MOLYKOTE®D-6900 Anti-Friction Coating can cover up to 17m2.This calculation is based on a15 μm thick MOLYKOTE®D-6900 Anti-Friction Coating dry film and does not take into account the losses generated during the application process.