Direct response to market needs & trends

Threaded connections in high-temperature-exposed applications like turbines or turbochargers require health-friendly lubrication to avoid seizing and to provide proper tightening torque.

MOLYKOTE® P-3700 Anti-Seize Paste

- Provides controlled friction during assembly

- Makes threaded connections simple to release after long periods of time at elevated temperatures

- Is environmentally friendly and health-friendly – no hazard labeling and precautionary statements

- Is free of intentional chromium ingredients

- Significantly reduces formation of hexavalent chromium when used on alloys with high chromium content at T >300°C

- Is free of any intentional calcium-based and magnesium-based ingredients

Performance advantages

- Significantly reduces formation of hexavalent chromium when used on chromium containing alloys at >300°C

- Wide service-temperature range: -30°C to 900°C

- Excellent heat resistance: Fully functional anti-seizing property up to 900°C; higher temperatures were not tested

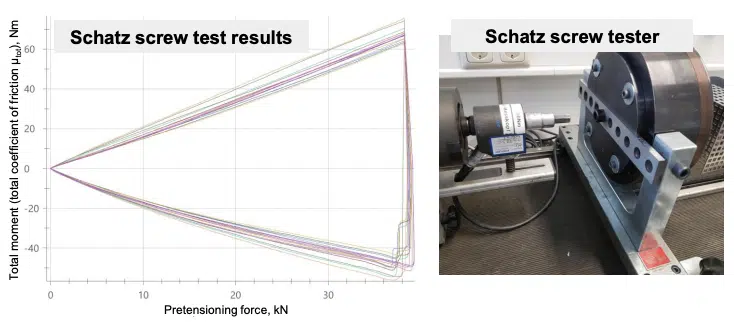

- Provides controlled friction during assembly, supporting exact tensioning

- Very good load-carrying capacity: 4-ball weld load of ~3,000 N

Reliable, safe operation of gas & steam turbines, turbochargers

Sustainability features

- Provides durable, decades-long performance, enabling maintenance after long periods of time at elevated temperatures to minimize material usage and waste

- Equipped with a friendly EHS profile (hazardous label-free) while still providing high performance under stress

- Prevents formation of hazardous substances, even in high-temperature applications

Technical information

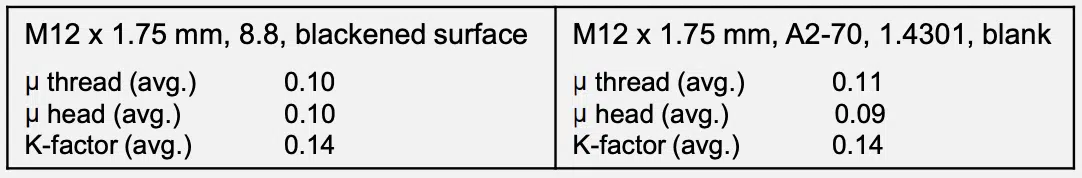

Screw testing

MOLYKOTE® P-3700 Anti-Seize Paste provides repeatable constant forces over multiple tightenings (5), independent of screw type.

New MOLYKOTE® P-3700 Anti-Seize Paste successfully suppresses yellowish hexavalent chromium formation at high temperatures while still offering fully functional antiseizing property.

P-3700 was designed primarily for gas/steam turbine applications. Here temperatures above 900 °C are very unlikely respectively do not exist. Higher temperatures have not been tested.

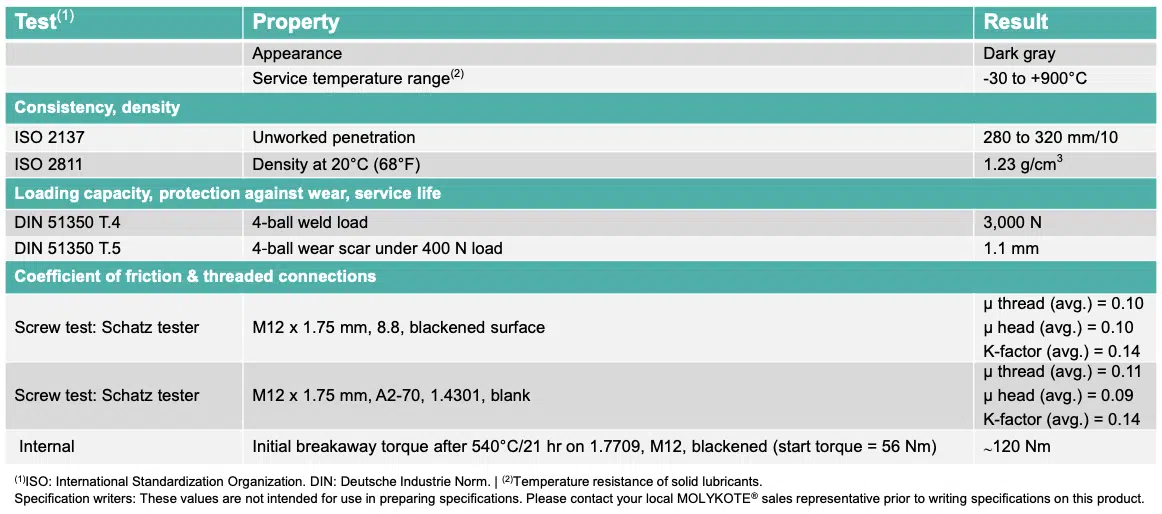

Preliminary technical data

Product summary

Key features

- Excellent anti-seize property, even after exposure up to 900°C

- Controlled friction during assembly, supporting exact tensioning

- High-purity paste

Benefits to customers

- Significantly reduces Cr(VI) formation when used on alloys with high chromium content at T >300°C

- Threaded connections are simple to release after long periods of time at elevated temperatures

- Environmentally friendly and health-friendly – currently free of hazards

- Global availability

Key properties

Provides controlled friction during assembly. Threaded connections simple to release after long period times at elevated temperatures. Environmental and health friendly – no hazard labeling and precautionary statements. No Cr(VI) formation issue when used on alloys with high chromium content at T > 500°C.

Applications

Suitable for screws, nuts and bolts found in industrial equipment exposed to elevated temperatures.

Performance benefits

- Applicable for high temperature (900°C) applications.

- Provides controlled friction on assembly supporting exact tensioning.

- Excellent anti-seize properties: Allows screws to be removed easily, even after long-term exposure at high temperatures.

- High purity paste (impurity sulfur, calcium and total halogen content regularly monitored).

- Free of intentional calcium ingredients.

- Suggested for alloys with high chromium content and stainless steel.

- Environmentally friendly and health-friendly – no hazard labeling and precautionary statements.

Click here to access the sell sheet for MOLYKOTE® P-3700.

Click here to access the presentation distribution for MOLYKOTE® P-3700.

https://www.dupont.com/