- Monday to Friday: 8:30 am – 5:00 pm

Electrolube ER 2188 is a UL approved, general purpose, two-part potting and encapsulating compound.

ER2188 is a UL approved, general-purpose, two-part potting and encapsulating compound. The system utilises a hardener free of DDM or other aromatic amines. The flame retardant technology used is of a ‘clean’ type leading to relatively low toxicity fumes and low smoke emission.

Sedimentation of the resin has been minimised by careful attention to the formulation. However, any sediment which may have occurred over long periods of time must be dispersed before removing any material from the container. This dispersion can be carried out (if necessary) by stirring with a broad bladed spatula or gently rolling the can. Take care not to introduce excessive amounts of air during this operation or it may be necessary to re-evacuate the resin. Sedimentation will be accelerated by storage at high temperatures. Sedimentation found in resin packs forms no problem since the sediment is re-mixed when the pack is used.

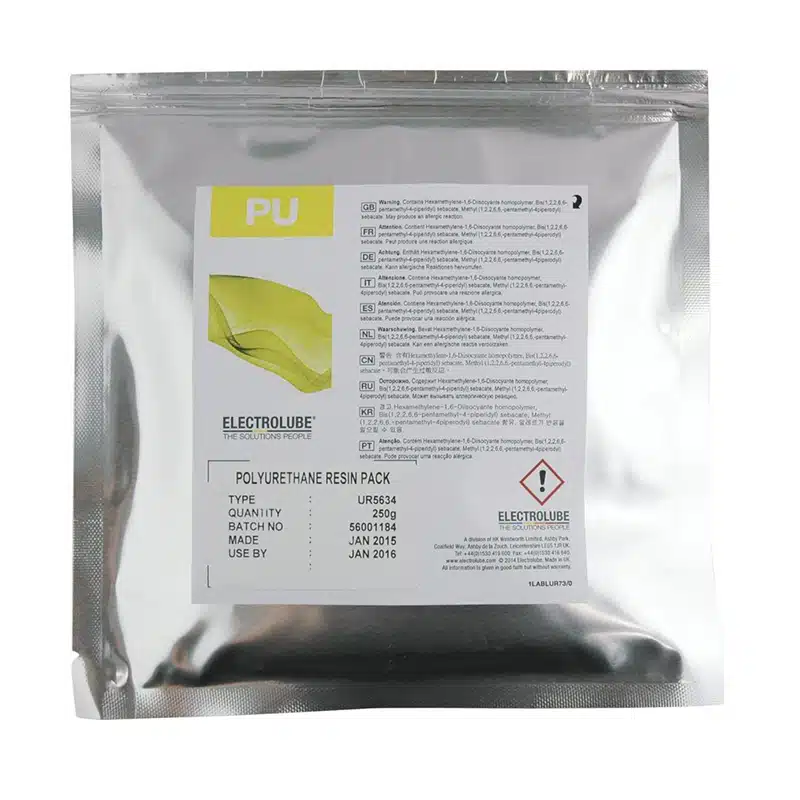

When in Resin pack form, the resin and hardener are mixed by removing the clip and moving the contents around inside the pack until thoroughly mixed. To remove the clip, remove both end caps, grip each end of the pack and pull apart gently. By using the removed clip, take special care to push unmixed material from the corners of the pack. Mixing normally takes from two to four minutes depending on the skill of the operator and the size of the pack. Both the resin and hardener are evacuated prior to packing so the system is ready for use immediately after mixing. The corner may be cut from the pack so that it may be used as a simple dispenser.

When mixing, care must be taken to avoid the introduction of excessive amounts of air. Automatic mixing equipment is available which will not only mix both the resin and hardener accurately in the correct ratio but do this without introducing air. Containers of Part A (Resin) and Part B (Hardener) should be kept sealed at all times when not in use to prevent the ingress of moisture. Bulk material must be thoroughly mixed before use. Incomplete mixing will result in erratic or partial curing.

It is far easier for machines & containers to be cleaned before the resin has been allowed to cure. Electrolube’s RRS is suitable for cleaning machines and containers and cured resin may be slowly softened and removed by soaking in our RRS.

Do not heat cure large volumes immediately. Allow these to gel at room temperature and post-cure at high temperature if required (refer to liquid properties for details). Small volumes (250ml) may be heat cured immediately.

When storing under very cold conditions, the hardener may crystallise. If this occurs, simply warm (40°C) the container gently until all crystals have re-melted.

Always refer to the Health & Safety data sheet before use. These can be downloaded from www.electrolube.com

To request any type of technical sheet or safety sheet.

With more than 200 sales professionals into the marketplace, we offer the most compelling local presence in your native language.

Please send us your request to receive customized support by your local dealer, either for specific products or special requirements.