Application-matched technology for global Tier 1 supplier

To ensure smooth, reliable and quiet operation of sliding sunroofs and panoramic roofs in all climates worldwide, an international Tier 1 automotive supplier relies on an application-matched MOLYKOTE® specialty polyalphaolefin (PAO) lubricant. For many years, the performance of MOLYKOTE® brand Smart LubricationTM solutions has been proven in meeting requirements of numerous global and regional vehicle OEM customers, helping to maximize the comfort, convenience and safety of sliding-roof operation.

Translucent MOLYKOTE® PAO lubricant resists dirt buildup to provide added cleanliness and extended service life on sliding-roof guides.

NOTE: The same PAO lubricant technology used on sliding roofs for international markets is available for North American production as MOLYKOTE® Grease.

Customer

A market-leading Tier 1 automotive supplier with extensive global design, engineering and manufacturing capabilities produces innovative sliding sunroofs and panoramic roofs for many OEM brands, meeting requirements to maximize value-added comfort, convenience and safety.

Challenge

To meet performance specifications of many global and regional vehicle OEM customers, this Tier 1 supplier needed an effective, application-matched lubricant that outperformed available options at low temperatures and ensured safer and more reliable opening and closing of its sliding-roof designs.

Solution

Translucent MOLYKOTE® PAO lubricant resists dirt buildup to provide added cleanliness and extended service life on sliding-roof guides.

The sunroof manufacturer collaborated with MOLYKOTE® – and the brand’s trusted expertise, problem-solving capabilities and broad technical support – to develop an advanced specialty PAO lubricant for use on sliding-roof guides to ensure smooth, reliable and quiet operation across a wide temperature range.

The opportunity

In developing early designs of tilt-up and sliding sunroofs for its home market and possible export, this automotive component manufacturer demonstrated a strong commitment to ensuring the highest-quality technology. White lithium greases were well-known, trusted and relatively economical lubricants for applications with sliding surfaces under heavy loads. However, none of the available options exactly met all of the performance specifications set by the sunroof design and engineering teams.

Trust in the MOLYKOTE® brand – and our specialty lubrication expertise, problem-solving capabilities for specific applications, broad technical support and ability to meet global supply requirements – led this global Tier 1 supplier to seek our help.

The Sunroof Guide Lubrication Challenge

An application-matched lubrication technology that could deliver consistently low friction was needed to ensure proper opening and closing forces across a range of sliding-roof designs. Low-temperature performance was a critical design parameter. And other key requirements added to the development challenge: The Smart LubricationTM solution also needed to address priorities such as a clean appearance, reduced noise, safety for vehicle occupants, compatibility with plastic materials, durability for extended service, and design flexibility for larger and more complex sliding roofs in the future.

Close collaboration between the sunroof design engineers and MOLYKOTE® application engineering and technical support (AETS) specialists – in our development and testing labs as well as in sunroof production plants for different markets – was essential.

The solution about Sunroof Guide Lubrication

The specific MOLYKOTE® PAO grease first developed for basic sunroof designs has grown in step with the manufacturer. Starting in the manufacturer’s home market and then expanding into other geographies, this MOLYKOTE® brand Smart LubricationTM solution is now maximizing functionality and comfort in all types of sunroofs, including popular panoramic roofs.

For more than two decades, as sliding roofs became an integral part of today’s vehicles in many regions, the MOLYKOTE® synthetic PAO lubricant has delivered key advantages and benefits:

- Superior performance with excellent lubrication and noise-damping capabilities

- Enhanced comfort with reduced noise, judder and vibration during sliding-roof opening and closing

- Consistent smoothness and reliability at temperatures from -45°C to 120°C (-49°F to 248°F)

- Increased safety by promoting a faster response to potential obstructions

- Good lightweighting potential with less friction and wear on different metals and resins

- Added cleanliness with low bleed, less oil separation and resistance to dirt buildup

- Extended service life with resistance to water washout, evaporation and corrosion

The same key advantages and benefits are available in MOLYKOTE® Grease, a specialty PAO lubricant for sliding-roof designs manufactured in North America.

Comparative performance testing

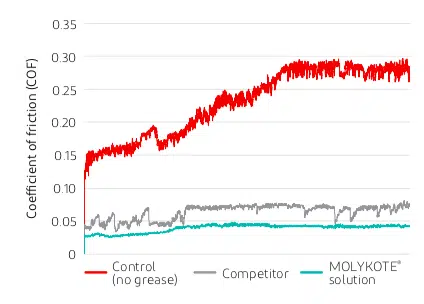

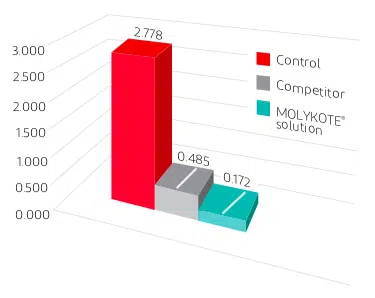

Figure 1. Coefficient of friction (COF) between TPEE and PP at ambient temperature, comparing the MOLYKOTE® solution, a competitive material and a control with no lubricant

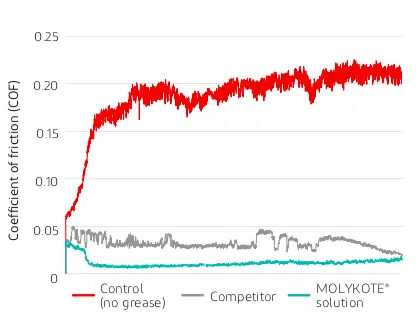

Figure 2. Coefficient of friction (COF) between TPEE and PP at 85°C, comparing the MOLYKOTE® solution, a competitive material and a control with no lubricant

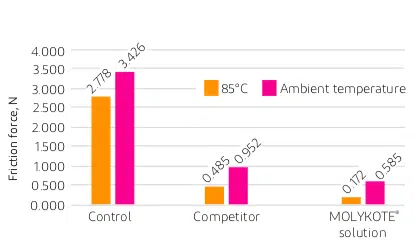

Figure 3. Average friction force between TPEE and PP, comparing the MOLYKOTE® solution and a competitive material against a control with no lubricant

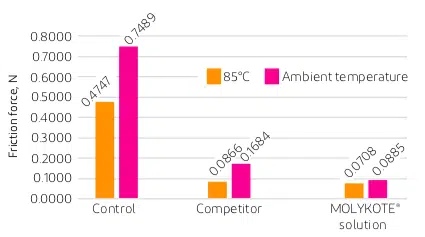

Figure 4. Standard deviation of friction force between TPEE and PP, comparing the MOLYKOTE® solution and a competitive material against a control with no lubricant

Figure 5. Mean friction force at 85°C, comparing the MOLYKOTE® solution, a competitive material and a control with no lubricant

Specialty PAO grease for North America

For high-performance lubrication of sunroofs and panoramic roofs manufactured in North America, MOLYKOTE® Grease offers the same consistently low friction as the proven, effective PAO lubricant technology used in international sliding-roof markets. This market-specific lubricant – a similar formulation of polyalphaolefin (PAO) oil thickened with lithium soap – ensures improved supply security, availability and cost. MOLYKOTE® Grease delivers the same key advantages and benefits of the globally proven Smart LubricationTM solution for meeting vehicle OEM performance specifications for all types of sliding-roof designs.

Typical properties

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local MOLYKOTE® Sales Application Engineer or MOLYKOTE® Customer Service before writing specifications on this product.

|

Test method |

Property |

MOLYKOTE® Grease |

|

Appearance |

White |

|

|

JIS K 2220 |

Penetration (worked 60 strokes) |

280 |

|

Service temperature range |

-45 to 120°C |

|

|

Dropping point |

210°C |

|

|

JIS K 2220 |

Bleed (24 hours at 100°C) |

2.4% |

|

JIS K 2220 |

Evaporation (22 hours at 99°C) |

0.2% |

|

Copper corrosion (24 hours at 100°C) |

1b |

|

|

Water washout (1 hour at 38°C) |

3.1% |

|

|

ASTM D2266 |

Four-ball wear scar |

0.58 mm |

|

JIS K 2220 |

Low-temperature torque (-40°C) – Starting torque |

90 mN•m 30 mN•m |

1ASTM: American Society for Testing and Materials; JIS: Japanese Industrial Standard.

Learn more about Sunroof Guide Lubrication: Contact us

To learn more about using MOLYKOTE® Grease for guide lubrication on sunroofs and panoramic roofs – or about driving vehicle design innovation with other high-performance specialty lubricants – contact your MOLYKOTE® technical representative.